Efficient steam boiler for gasification and combined combustion of pulverized coal

A technology for steam boilers and pulverized coal, which is applied in steam boilers, granular/powdered fuel gasification, steam generation, etc., can solve the problems of large operation and management workload, affecting high temperature flue gas burnout rate, and increasing equipment investment, etc. To achieve the effect of saving space, convenient load adjustment, high combustion efficiency and thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

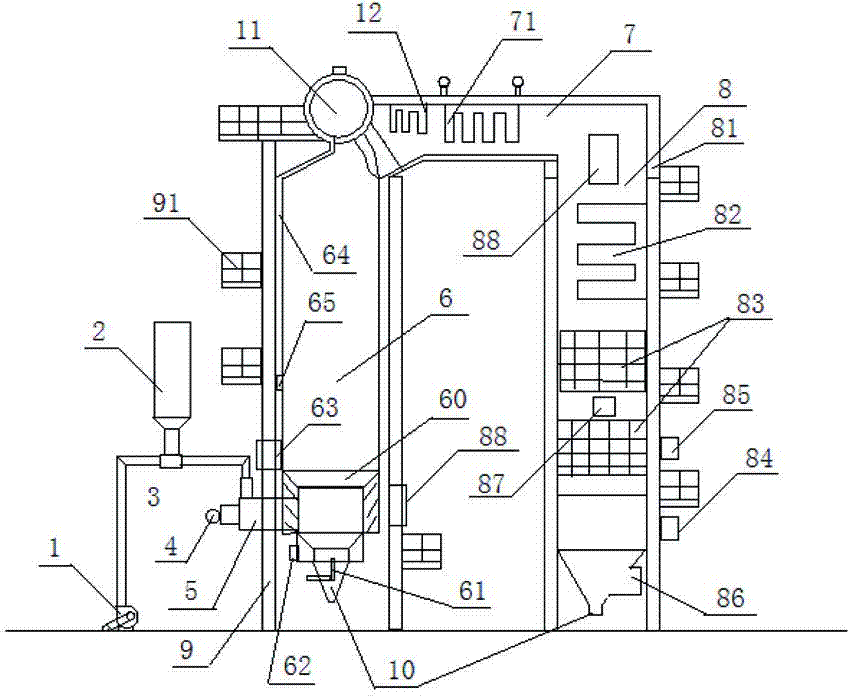

[0014] Such as figure 1 A high-efficiency pulverized coal gasification and pulverized coal composite combustion steam boiler shown includes a blower 1, a pulverized coal bin 2, a pulverized coal delivery pipeline 3, a burner 4, a gasification chamber 5, a furnace 6, a horizontal flue 7, Steam superheater 12, tail shaft 8, boiler pillar 9, the blower 1 is connected to the pulverized coal bin 2, and is connected to the gasification chamber 5 through the pulverized coal delivery pipeline 3, and the burner 4 is connected to the gasification chamber 5; The gasification chamber 5, the furnace 6, the horizontal flue 7, and the tail shaft 8 are connected in sequence, and are installed on the boiler pillar 9 to form a ∏ shape; an unburned belt 60 is arranged above the connection between the furnace 6 and the gasification chamber 5, and The bottom of the furnace 6 is provided with a jet air inlet 61 and a secondary air inlet 62, and a tertiary air inlet 63 is arranged at the outlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com