A hydraulically loaded machine-fluid mixed flow test platform and its application

A hydraulic loading and testing platform technology, which is applied in vehicle testing, mechanical component testing, machine/structural component testing, etc., can solve the problems of manpower and material resources, long cycle time, high cost, etc., and achieve cost saving and low production cost , the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

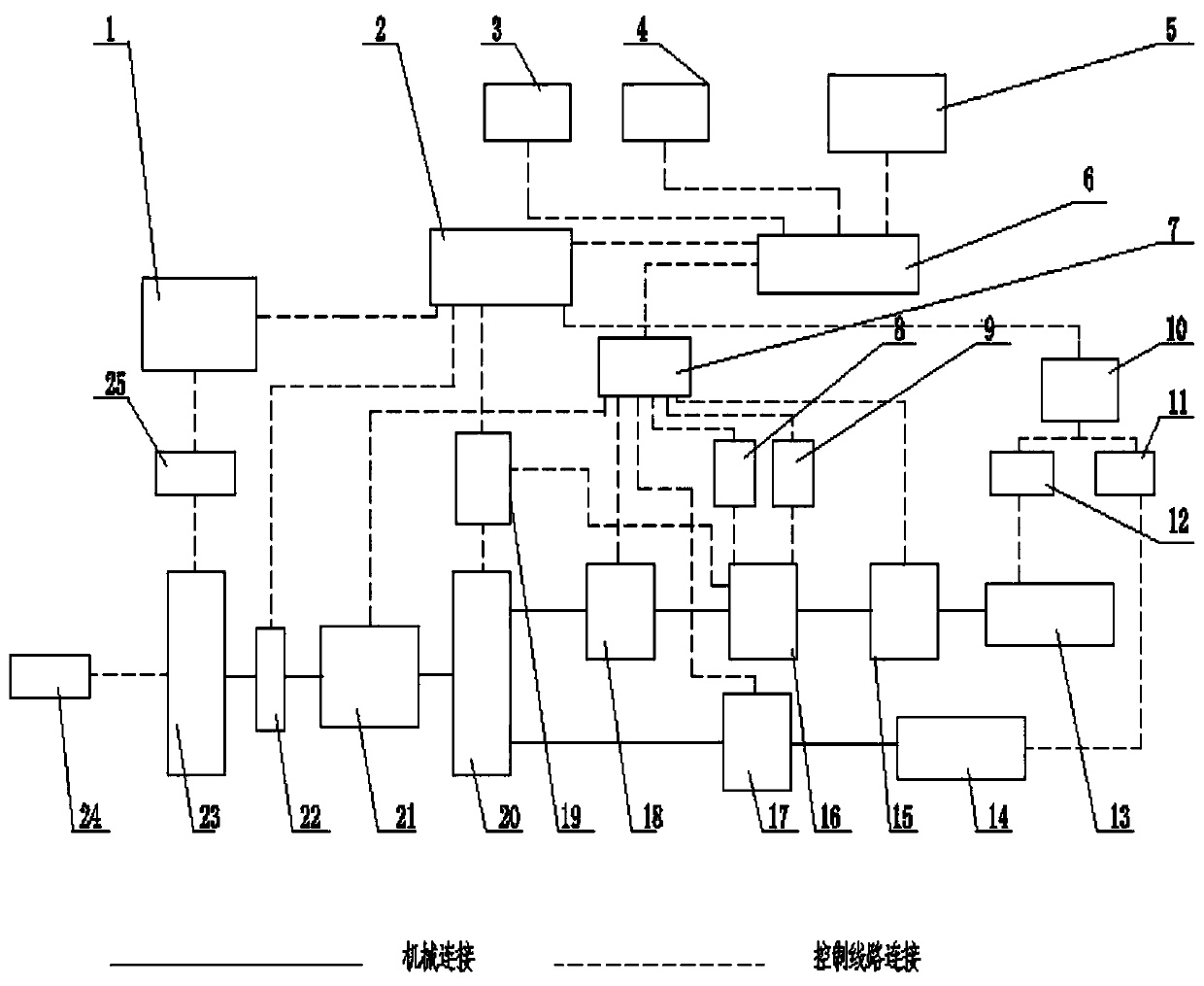

[0052] Such as Figure 1 to Figure 3 As shown, this embodiment provides a hydraulically loaded machine-fluid mixed flow test platform, which mainly includes two aspects: a mechanical part and a control part:

[0053] The mechanical part includes:

[0054] A hydraulic motor 23, an electromagnetic clutch 22, an input speed torque sensor 21, and a shunt mechanism 20 connected in sequence at the input end;

[0055] One output end of the shunt mechanism 20 is sequentially connected to the rotational speed torque sensor 17 of the mechanical transmission unit and the hydraulic loading system 14 at the output end of the mechanical transmission unit;

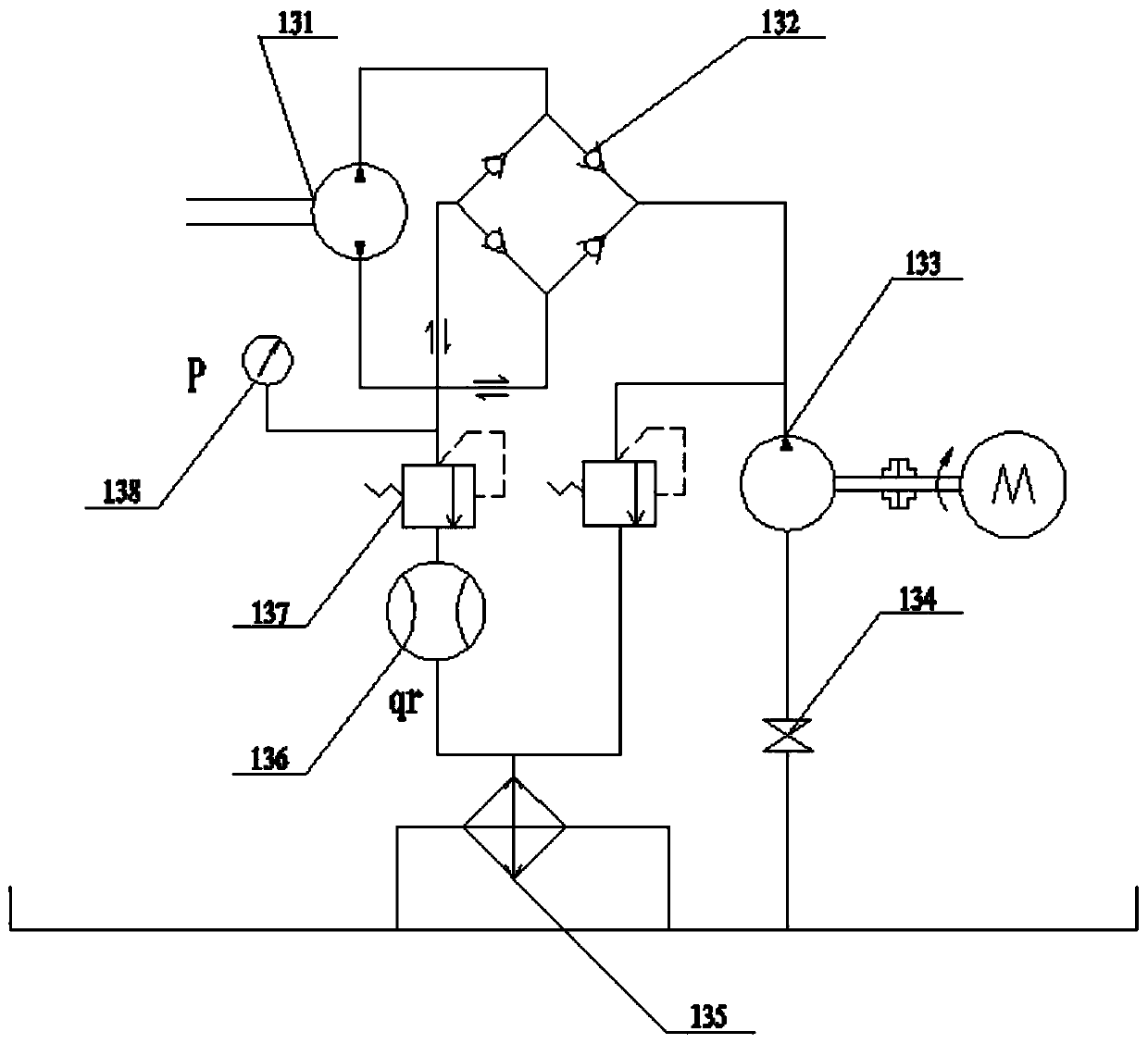

[0056] The other output end of the shunt mechanism 20 is sequentially connected to the speed torque sensor 18 at the input end of the hydraulic transmission unit, the tested hydraulic transmission unit 16, the speed torque sensor 15 at the output end of the hydraulic transmission unit, and the hydraulic loading system 13 at the output e...

Embodiment 2

[0067] Such as Figure 4 As shown, a working method of a hydraulically loaded machine-hydraulic mixed flow test platform uses the technical solution of Embodiment 1 to simulate the power change of the power demand field in the vehicle power transmission system. The specific operation process is as follows:

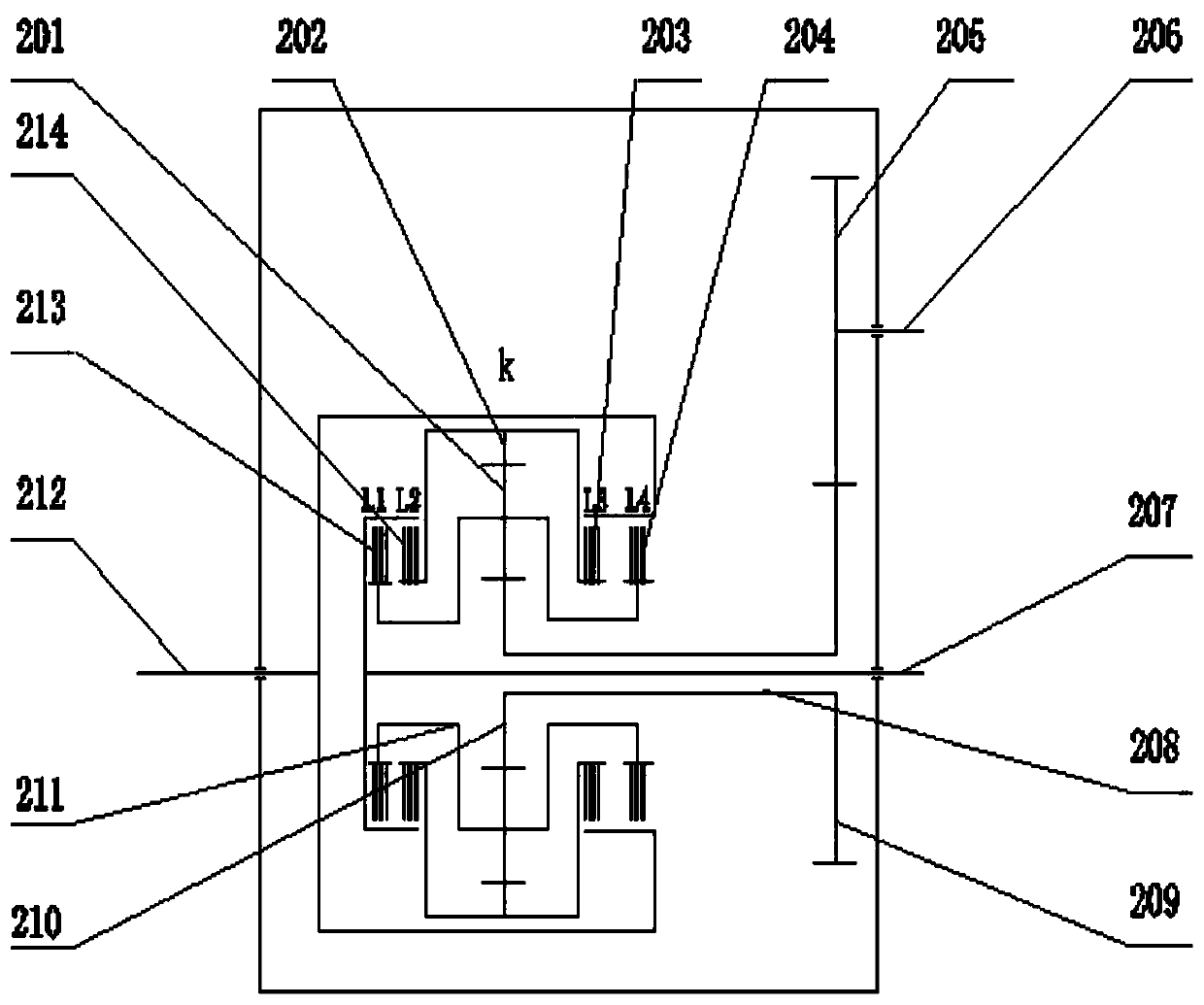

[0068] The operating modes of the four clutch engagement states in the diverter mechanism 20 are controlled by the diverter mechanism controller 19:

[0069] (1) The power transmission mode of the hydraulic transmission unit forward confluence

[0070] When the clutch L1213 and the clutch L3203 are engaged, the coupling shaft 207 of the mechanical transmission unit is connected to the ring gear 202 of the planetary gear system, and the coupling shaft 206 of the hydraulic transmission unit is always connected to the sun gear 210 of the planetary gear system through the fixed gear transmission formed by gear A205 and gear B209 , the input shaft 212 of the splitter mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com