Solid particulate matter heat storage and release device, system and method

A solid particle heat storage and release technology, which is applied in the steam generation method using heat carrier, steam generation method, heat storage equipment, etc., can solve the problems of high cost, small application range, short service life, etc., and reduce construction costs , improve the efficiency of the whole plant, and simplify the effect of civil work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with specific embodiment, further illustrate the present invention.

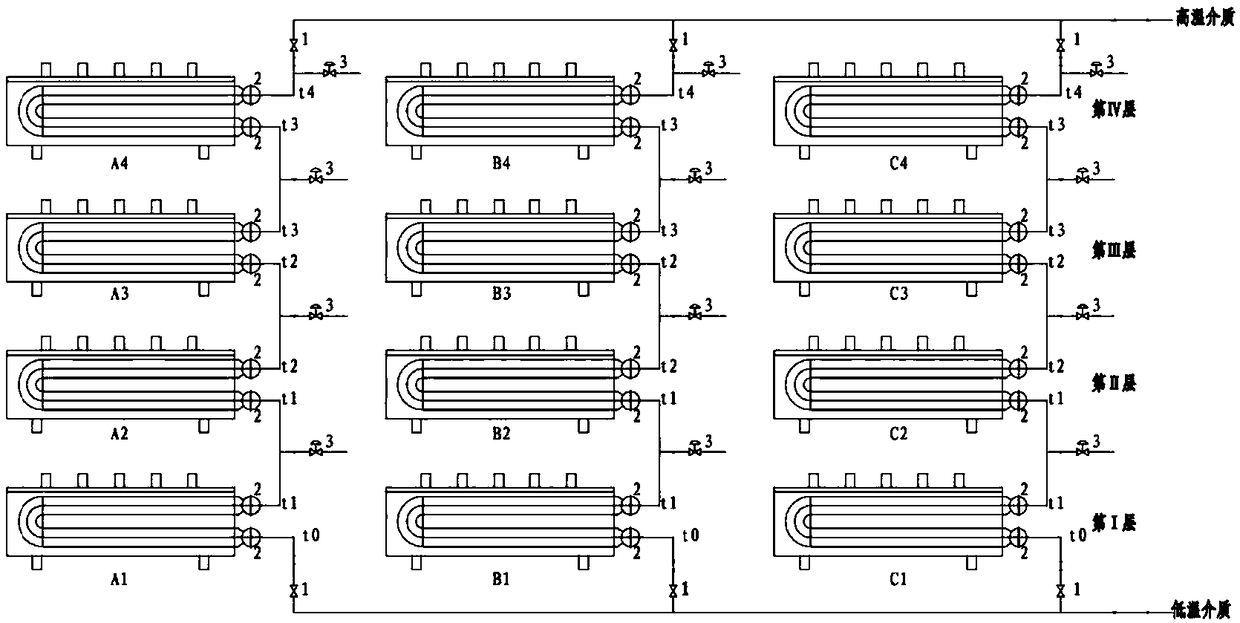

[0025] This embodiment provides a solid particle heat storage and release device, including a heat storage and exchange container, a heat exchange tube is buried inside the heat storage and exchange container, a heat storage medium is placed in the heat storage and exchange container and outside the heat exchange tube, and the heat exchange A heat exchange medium circulates inside the tube.

[0026] The heat storage and exchange container adopts a rectangular parallelepiped, cube, cylinder or similar space structure, and the shell material is made of carbon steel, stainless steel, alloy steel or other refractory materials.

[0027] The heat exchange tube adopts smooth tube or finned tube, and the material is carbon steel, stainless steel or alloy steel, which can be straight tube, bent tube, serpentine tube, U-shaped tube, etc.

[0028] The heat storage medium adopts solid partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com