Finished product ammonium nitrate aqueous solution pH value controlling method and device thereof

A control device and control method technology, applied in the direction of explosives, etc., can solve problems such as explosions, achieve low consumption, low production costs, and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

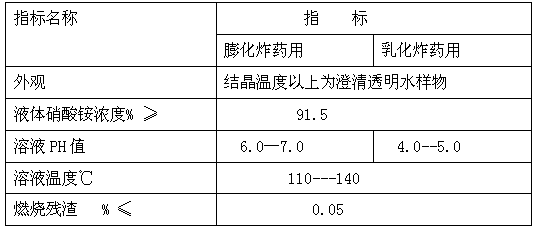

[0046] A kind of control method of finished product ammonium nitrate aqueous solution pH value, comprises the following steps:

[0047] (1) First open the vent valve on the top of the storage tank to communicate with the atmosphere, keep the inside of the storage tank at normal pressure, transport the finished ammonium nitrate aqueous solution to the storage tank, and adjust the nitric acid in the storage tank through the heater installed at the bottom of the storage tank. The temperature of the ammonium aqueous solution is 110°C;

[0048](2) Open air compressor, make its outlet pressure be 0.1Mpa, compressed air enters in the ammonium nitrate aqueous solution by being located at the air distributor inside storage tank after drying, degreasing, it is stirred;

[0049] (3) Start the circulating delivery pump located at the outlet of the storage tank, and mix the ammonium nitrate aqueous solution for 10 minutes by self-circulation;

[0050] (4) Sampling and analyzing the PH val...

Embodiment 2

[0053] A kind of control method of finished product ammonium nitrate aqueous solution pH value, comprises the following steps:

[0054] (1) First open the vent valve on the top of the storage tank to communicate with the atmosphere, keep the inside of the storage tank at normal pressure, transport the finished ammonium nitrate aqueous solution to the storage tank, and adjust the nitric acid in the storage tank through the heater installed at the bottom of the storage tank. The temperature of the ammonium aqueous solution is 140°C;

[0055] (2) open air compressor, make its outlet pressure be 0.3Mpa, compressed air enters in the ammonium nitrate aqueous solution by being located at the air distributor inside storage tank after drying, degreasing, it is stirred;

[0056] (3) Start the circulating delivery pump located at the outlet of the storage tank, and mix the ammonium nitrate aqueous solution for 15 minutes by self-circulation;

[0057] (4) Sampling and analyzing the PH va...

Embodiment 3

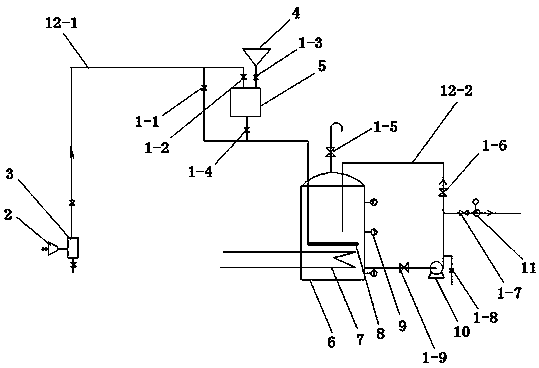

[0060] Such as figure 1 As shown, a control device for realizing the pH value of the above-mentioned finished ammonium nitrate aqueous solution includes a storage tank 6, and an air distributor 8 is arranged horizontally in the middle of the storage tank 6, and the air distributor 8 passes through the first pipeline 12-1 and is located in the storage tank. The air compressor 2 outside the tank 6 is connected, and the first pipeline 12-1 is connected with an acid-base tank 5 for adjusting the pH value; the outlet end at the bottom of the storage tank 6 is connected with a circulation delivery pump 10, and the outlet of the circulation delivery pump 10 The end communicates with the upper end of the storage tank 6 through the second pipeline 12-2, and the outlet end of the second pipeline 12-2 is located at the middle and upper part of the storage tank 6.

[0061] Further, in order to improve the cleanliness of the compressed air and avoid the impact on the ammonium nitrate aqueo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com