High-efficiency gasification device suitable for multiple kinds of coal

A gasification device and multi-coal technology, which is applied in the direction of gasification device feeding tools, gasification process, granular/powdered fuel gasification, etc. Complicated and other issues, to achieve the effect of low cost, convenient load adjustment and high washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

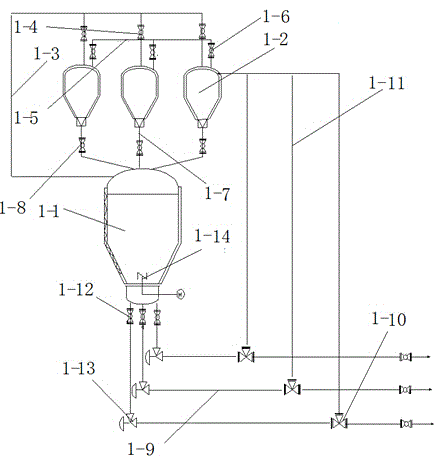

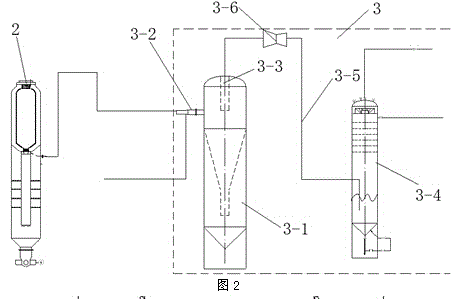

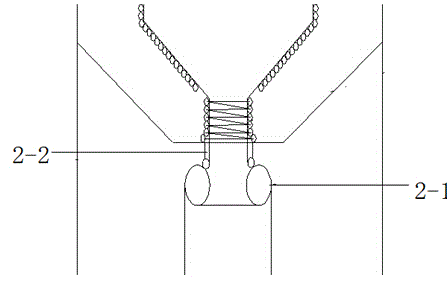

[0012] Embodiment of the present invention: the structure of the high-efficiency gasification device applicable to multiple coal types is as follows figure 1 As shown, it includes pulverized coal conveying equipment 1, gasifier 2 and synthesis gas purification equipment 3. The composition of pulverized coal conveying equipment 1 includes a feeding tank 1-1, and three pulverized coal lock hoppers 1 are arranged above the feeding tank 1-1. -2, each pulverized coal lock hopper 1-2 is connected to the top of the feeding tank 1-1 through the feeding pipe 1-7, and the feeding valve 1-8 is arranged on the feeding pipe 1-7, and each pulverized coal The lock hoppers 1-2 are connected to the feeding tank 1-1 through the tank body pressure equalizing pipe 1-3, and the tank body balancing valve 1-4 is arranged on the tank body pressure equalizing pipe 1-3, and three pulverized coal lock hoppers 1 There is a lock bucket pressure equalizing pipe 1-5 connected between -2, and a lock bucket p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com