A method for deoxygenating and finely desulfurizing coke oven gas

A coke oven gas and fine desulfurization technology, which is applied in separation methods, gas dedusting, chemical instruments and methods, etc., can solve the problems of blocked catalyst channels, catalyst bed overheating, catalyst deactivation, etc., and achieves convenient load adjustment and operation Good reliability and safety, high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

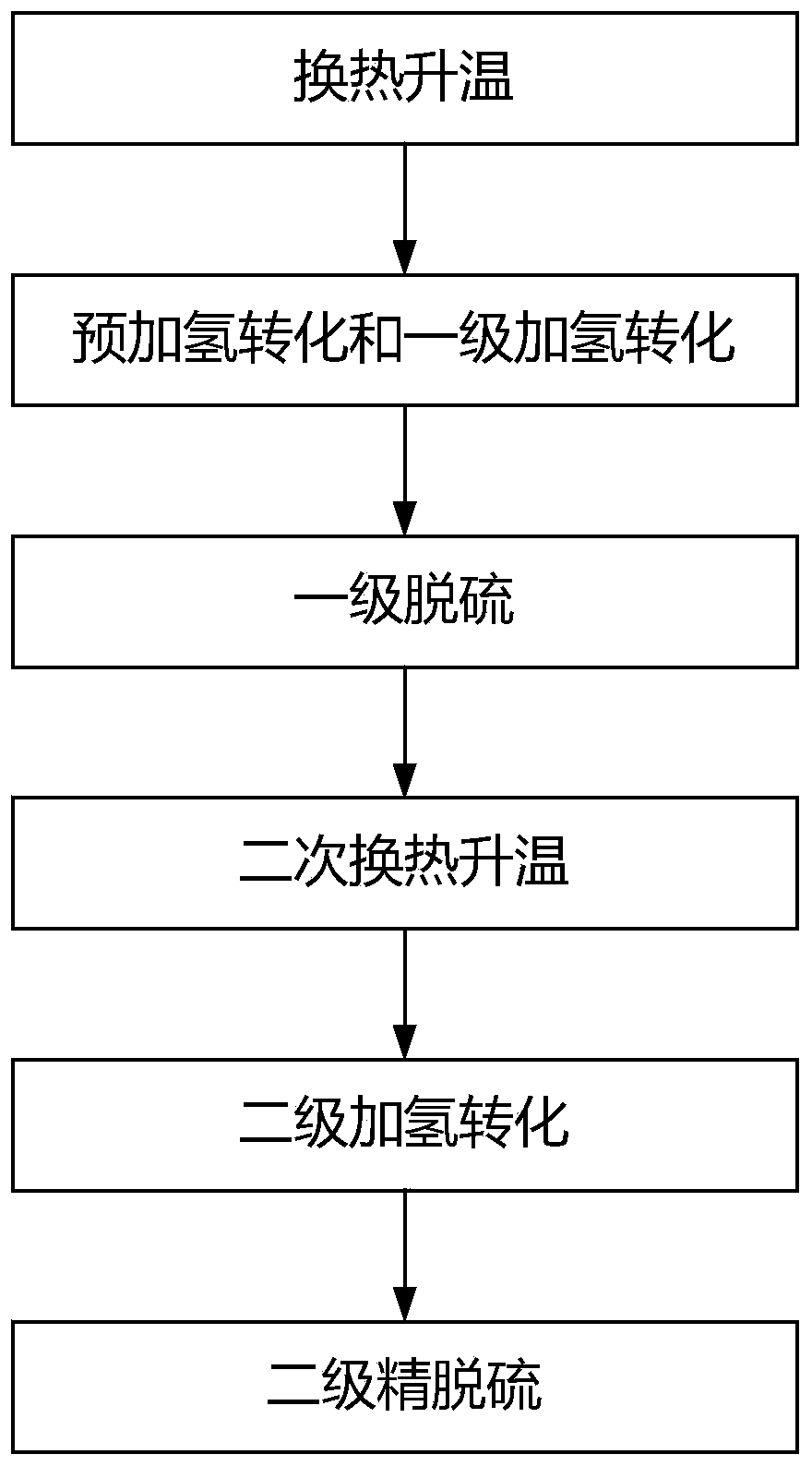

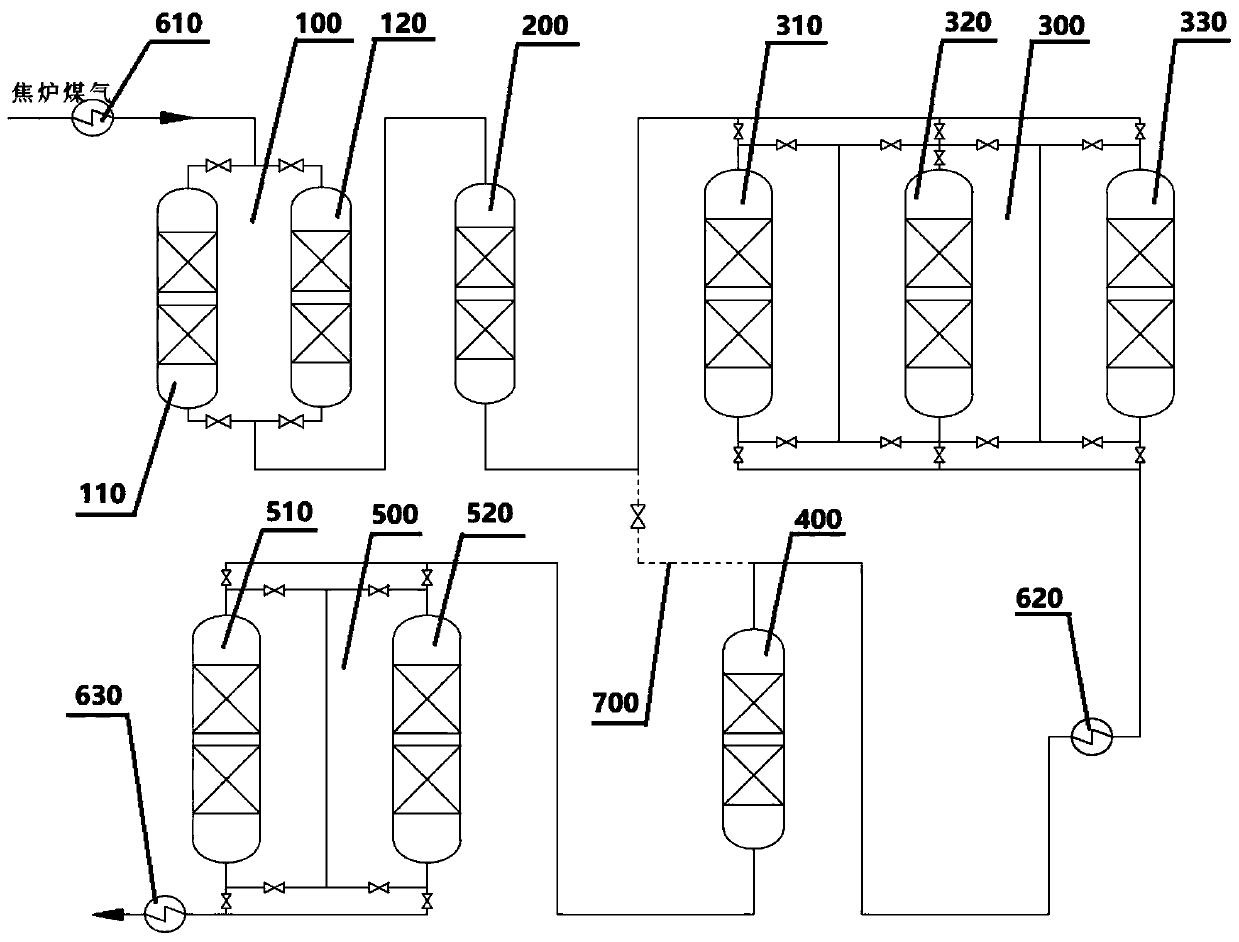

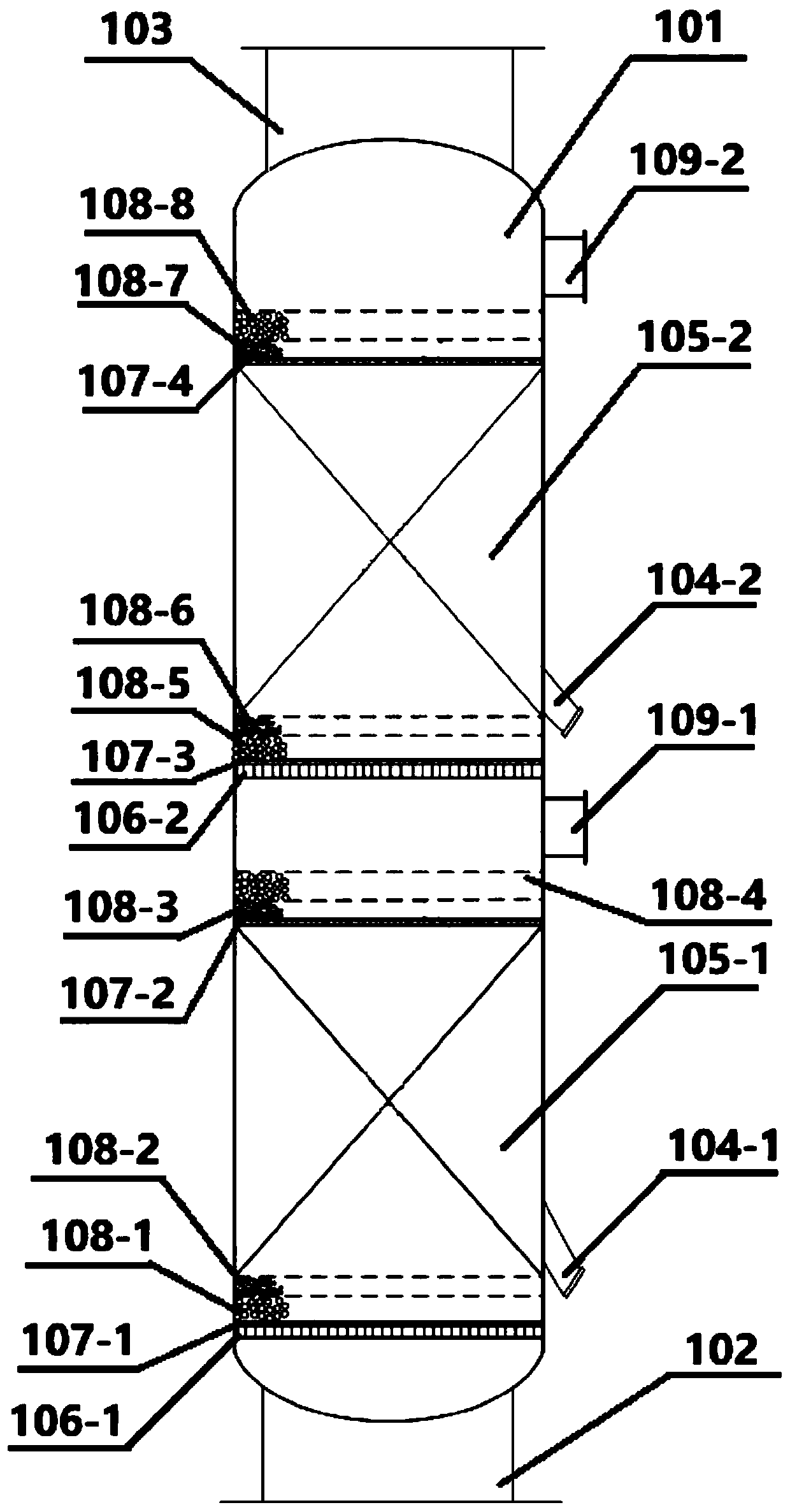

[0097] A method for deoxidizing and fine desulfurizing coke oven gas, comprising the following steps:

[0098] S0), initial purification of coke oven gas

[0099] The flow rate of coke oven gas before initial purification is 83052Nm 3 / h, the pressure is 0.005Mpa, and the temperature is 20°C; among the active ingredients, the volume fraction of methane is 20.8%, the volume fraction of hydrogen is 60.31%, the volume fraction of carbon monoxide is 8.9%, and the volume fraction of oxygen is 0.82 %, the volume fraction of carbon dioxide is 2.58%, and the content of tar and dust is 0.015g / Nm 3 , the content of hydrogen sulfide is 50mg / Nm 3 , the content of other sulfides is 155.2mg / Nm 3 .

[0100] The initial purification of coke oven gas includes the following steps:

[0101] S01), dust removal and detar

[0102] Use an electric tar catcher to dedust and detar the coke oven gas, so that the total amount of dust and tar in the coke oven gas is not higher than 3 mg / Nm 3 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com