Electric refrigerating unit for refrigerated vehicle

A refrigeration unit and vehicle electric technology, applied in vehicle parts, heating/cooling equipment, air handling equipment, etc., can solve the technical difficulty of power switching, energy regulation and cooling capacity control, low efficiency, pollution emission, volume and Large quality and other issues, to achieve the effect of reliable and efficient energy regulation scheme, compact system, and high temperature control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

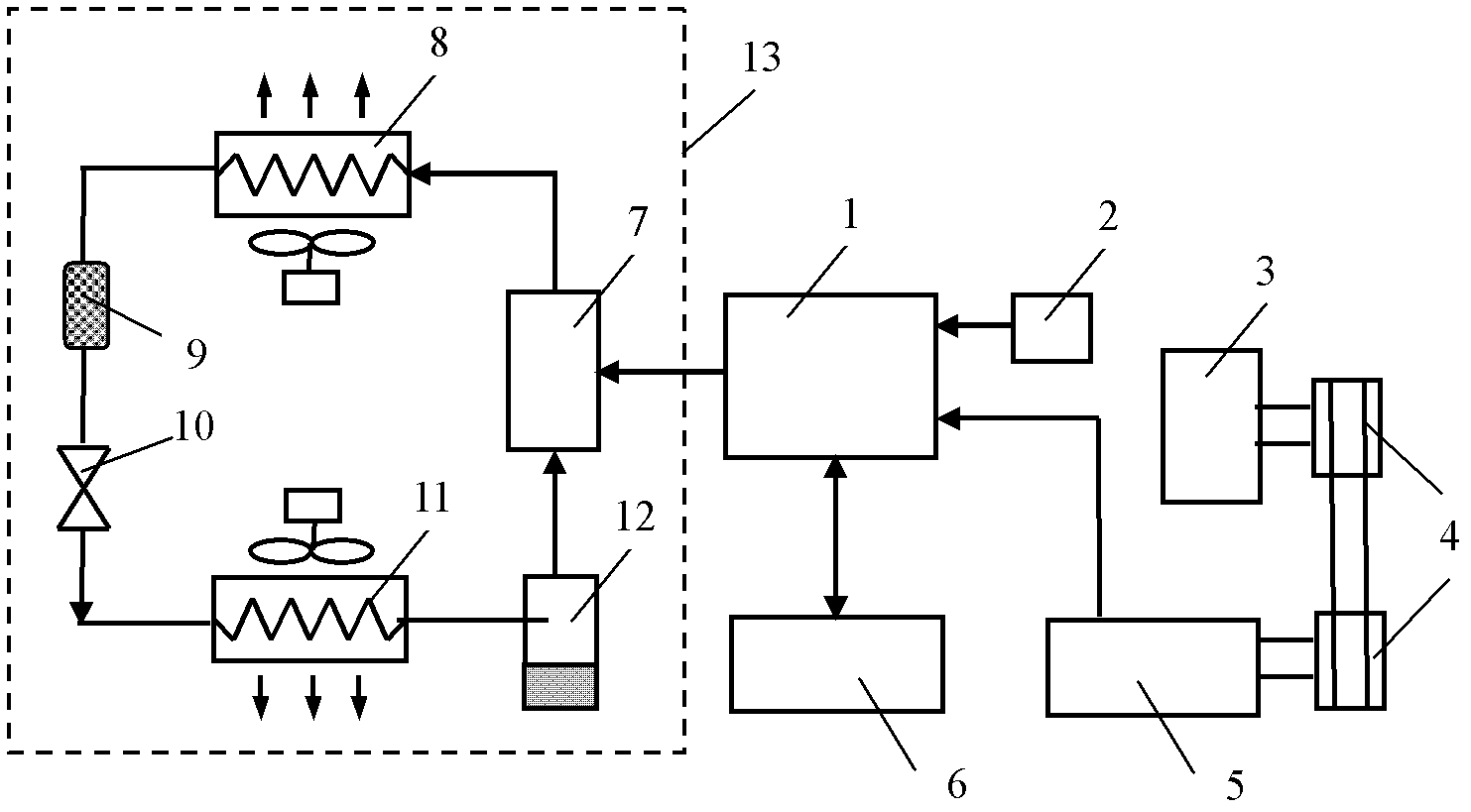

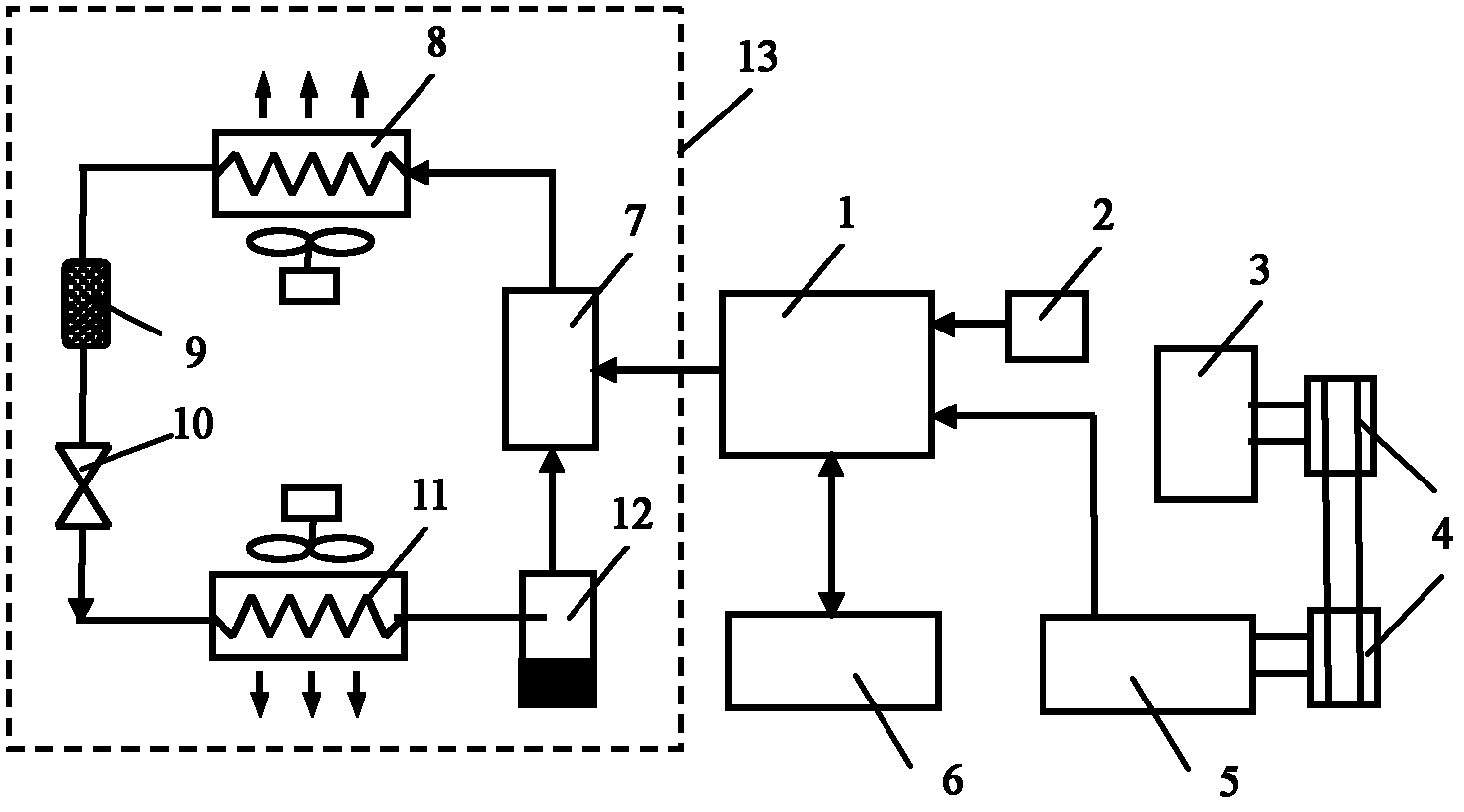

[0023] see figure 1 In this embodiment, the electric refrigerating unit for refrigerated vehicles is composed of an electric energy conversion drive system and a refrigeration cycle system 13 with the frequency conversion controller 1 as the core.

[0024] A fully enclosed variable frequency refrigeration compressor 7 is configured in the refrigeration cycle system 13, and the connection circuit of the refrigeration cycle system 13 is: the air outlet of the fully enclosed variable frequency refrigeration compressor 7 is connected to the inlet of the air-cooled condenser 8, and in the air-cooled condenser The outlet port of 8 is connected to dry filter 9, electronic expansion valve 10, evaporator 11, gas-liquid separator 12 in sequence, and then connected to the air inlet of refrigeration compressor 7; fully enclosed frequency conversion refrigeration compressor 7 is controlled by frequency conversion controller 1 output power drive;

[0025] The input end of the frequency con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com