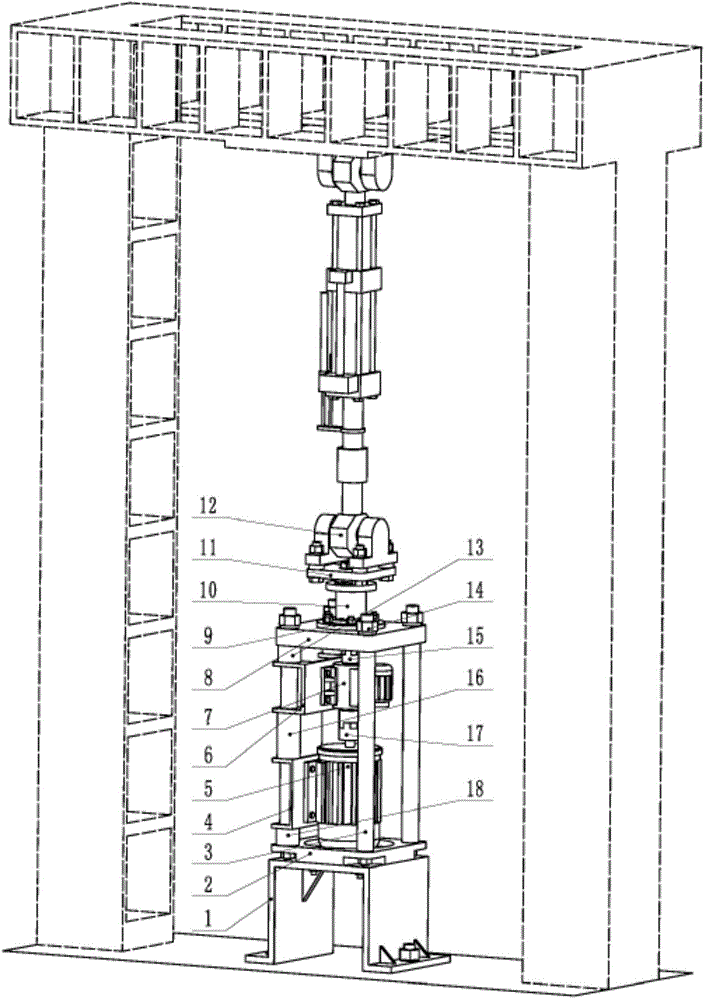

Ball screw servo loading test device based on hydraulic servo system

A technology of loading test device and hydraulic servo system, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of high price, long loading test device, inability to display and control the load in real time, etc., and achieve convenient load adjustment and simple structure. , the effect of easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

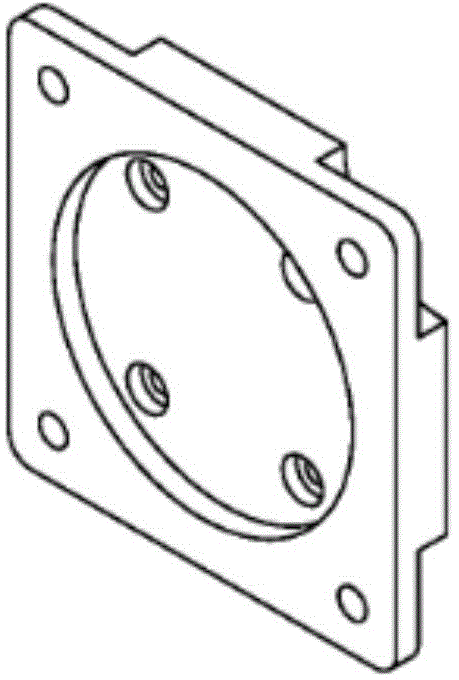

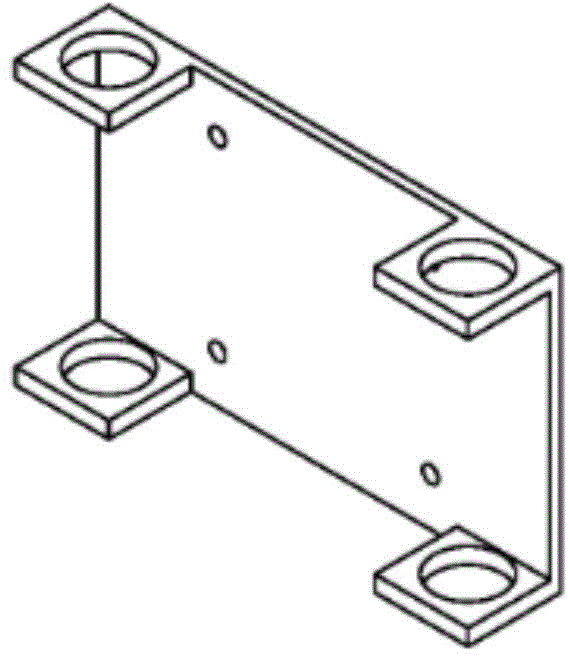

[0026] A ball screw servo loading test device based on a hydraulic servo system, comprising a floor base 1, a base plate 2 fixed on the floor base 1, a mounting seat 8 fixed on the top of the base plate 2 through a supporting steel pipe 3 in the vertical direction, and the base plate 2. There are four stepped holes in the middle and through holes at the four corners. The bottom plate 2 is fixed on the floor base 1 through the four stepped holes in the middle. The steel pipes 3 are installed vertically in the four corner through holes of the bottom plate 2 and fixed respectively, and are located above the bottom plate 2. The mounting base 8 is fixed on the other end of the four supporting steel pipes 3, and is fixed on the supporting steel pipes 3 by tightening the nuts 14. Above, the supporting steel pipe 3 plays the role of supporting the mounting seat 8, the structure of the motor fixing plate 4 is the same as that of the speed torque sensor fixing plate 6, and its holes are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com