Precision online detecting method of rolling mill equipment

A detection method and rolling mill technology, applied in metal processing equipment, length measuring devices, metal rolling, etc., can solve the problem of inability to distinguish vertical equipment accuracy or rolling mill circumferential equipment accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

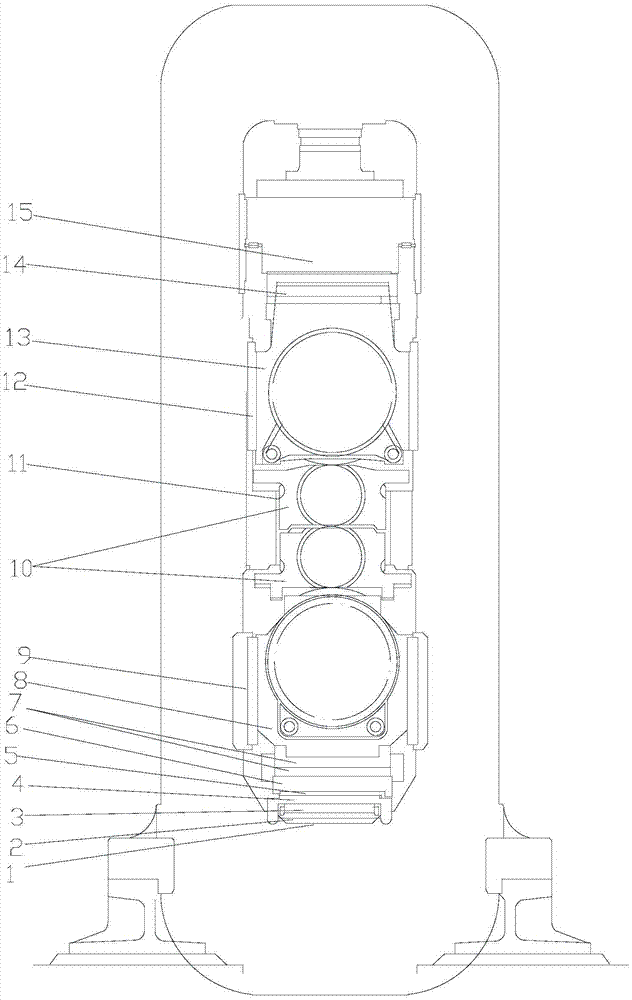

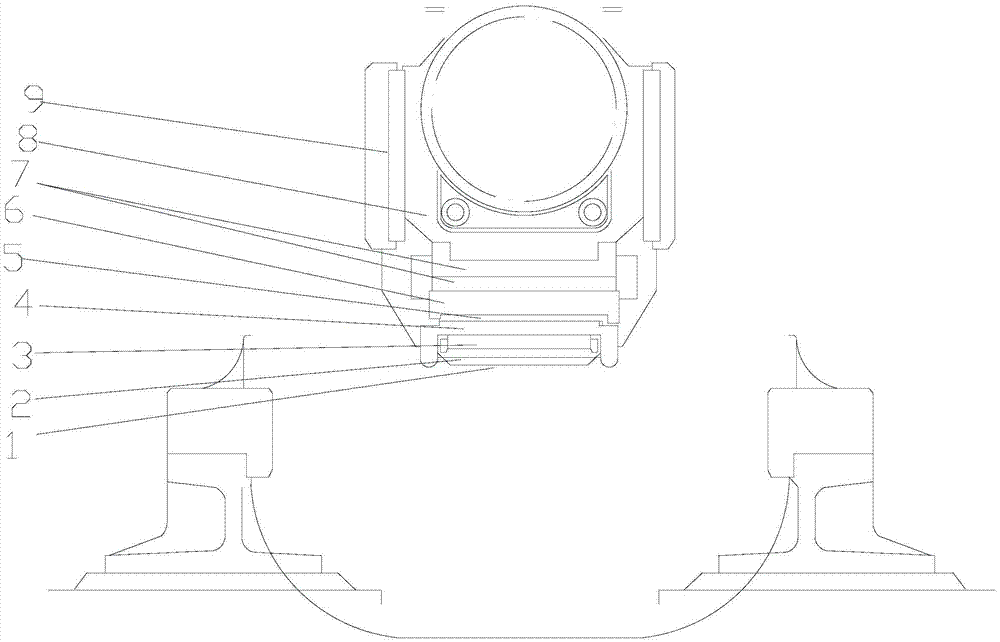

Image

Examples

Embodiment Construction

[0054] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

[0055] An online detection method for rolling mill equipment accuracy involved in the present invention includes the following steps

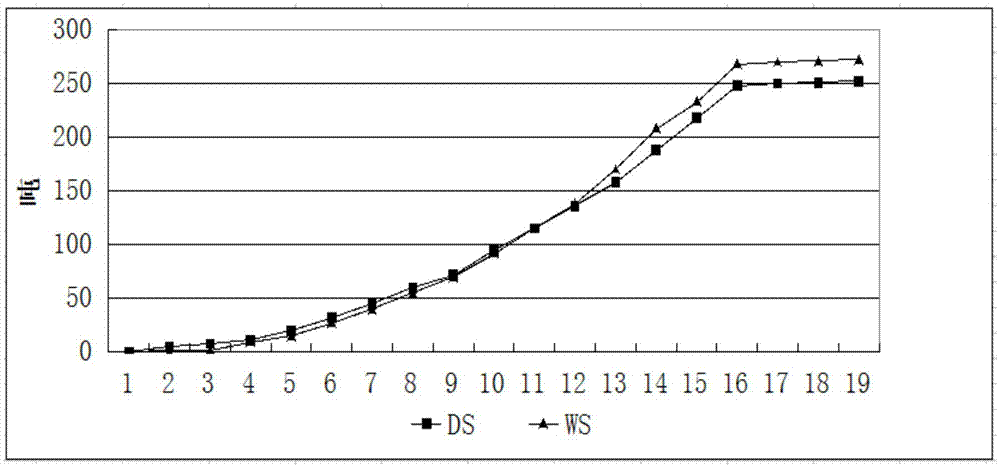

[0056] 1. After the roll gap is leveled, carry out the zero adjustment of the roll gap. The two sides (WS, DS) are simultaneously pressed down to the rolling force and 500t±10t. After two adjustments, the following two conditions are met at the same time:

[0057] a), the sum of the rolling forces on both sides is (F WS +F DS )=500t±10t,

[0058] b) The rolling ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap