Valve with ceramic disc

A valve assembly, flange technology, applied in the direction of lift valve, multi-way valve, valve device, etc., can solve problems such as increasing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The disc assembly of the instant disclosure is typically part of a valve. The valve provides a housing with at least one inlet and with at least one outlet. The valve according to the instant disclosure also provides a valve element.

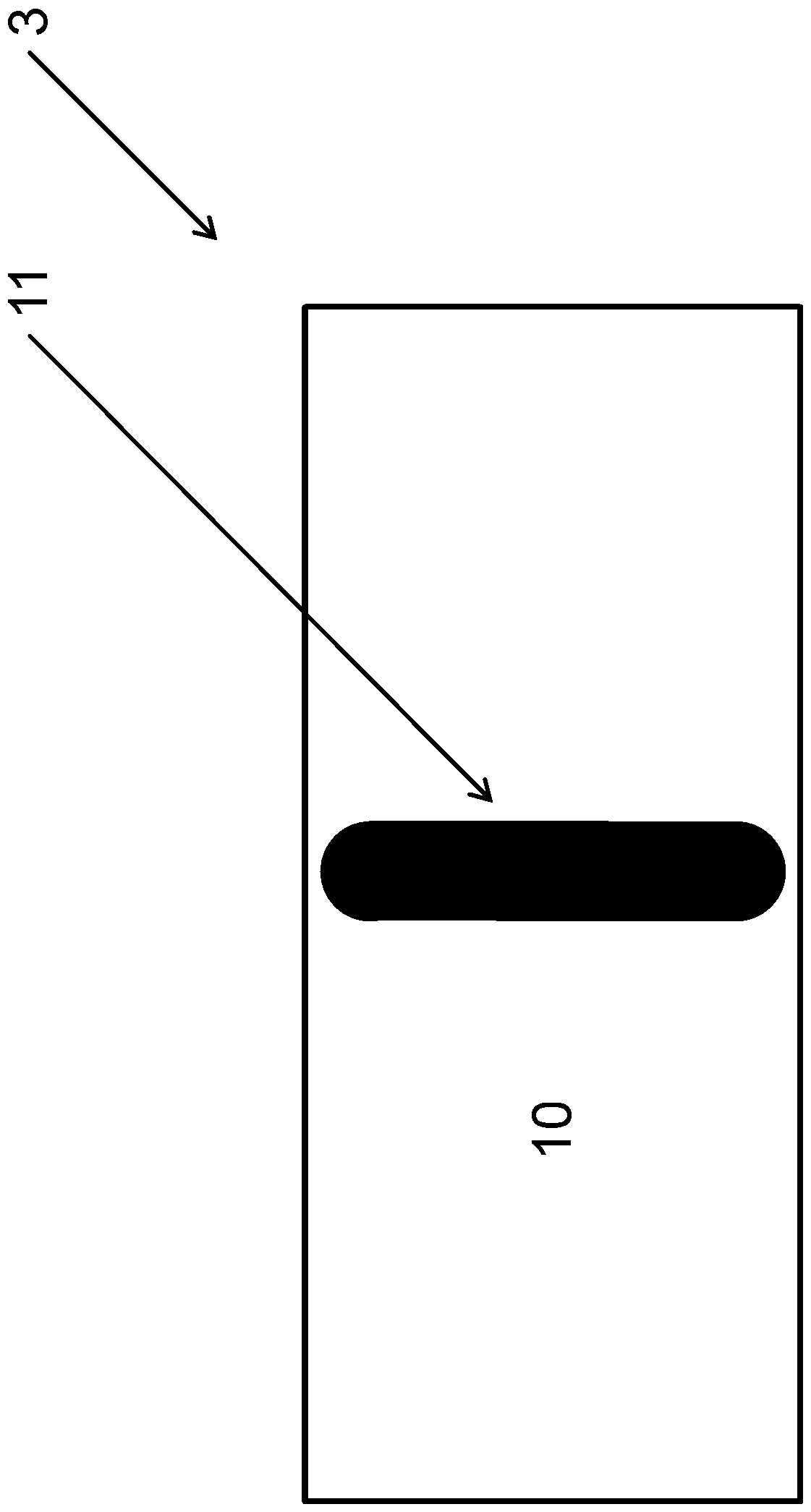

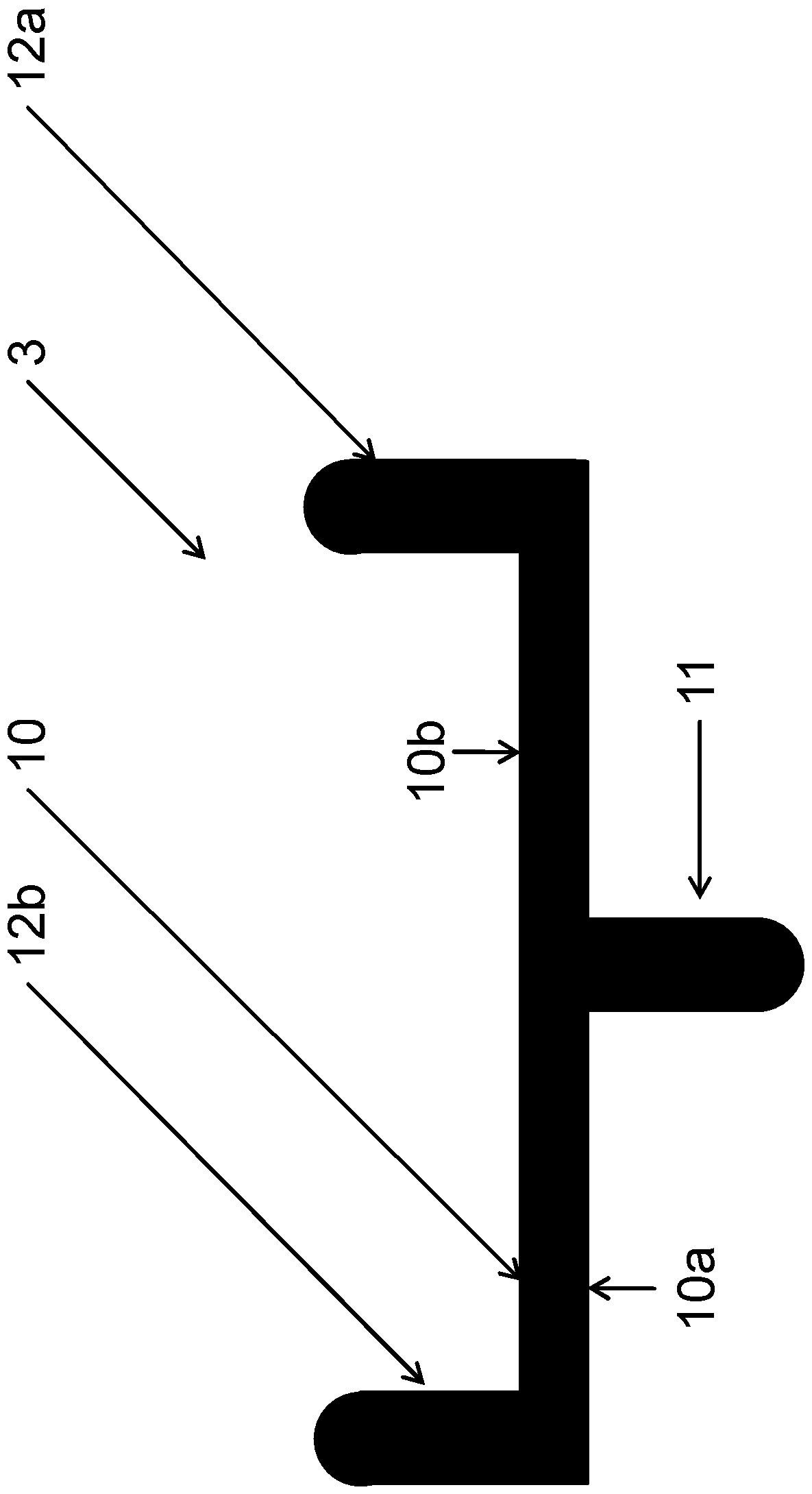

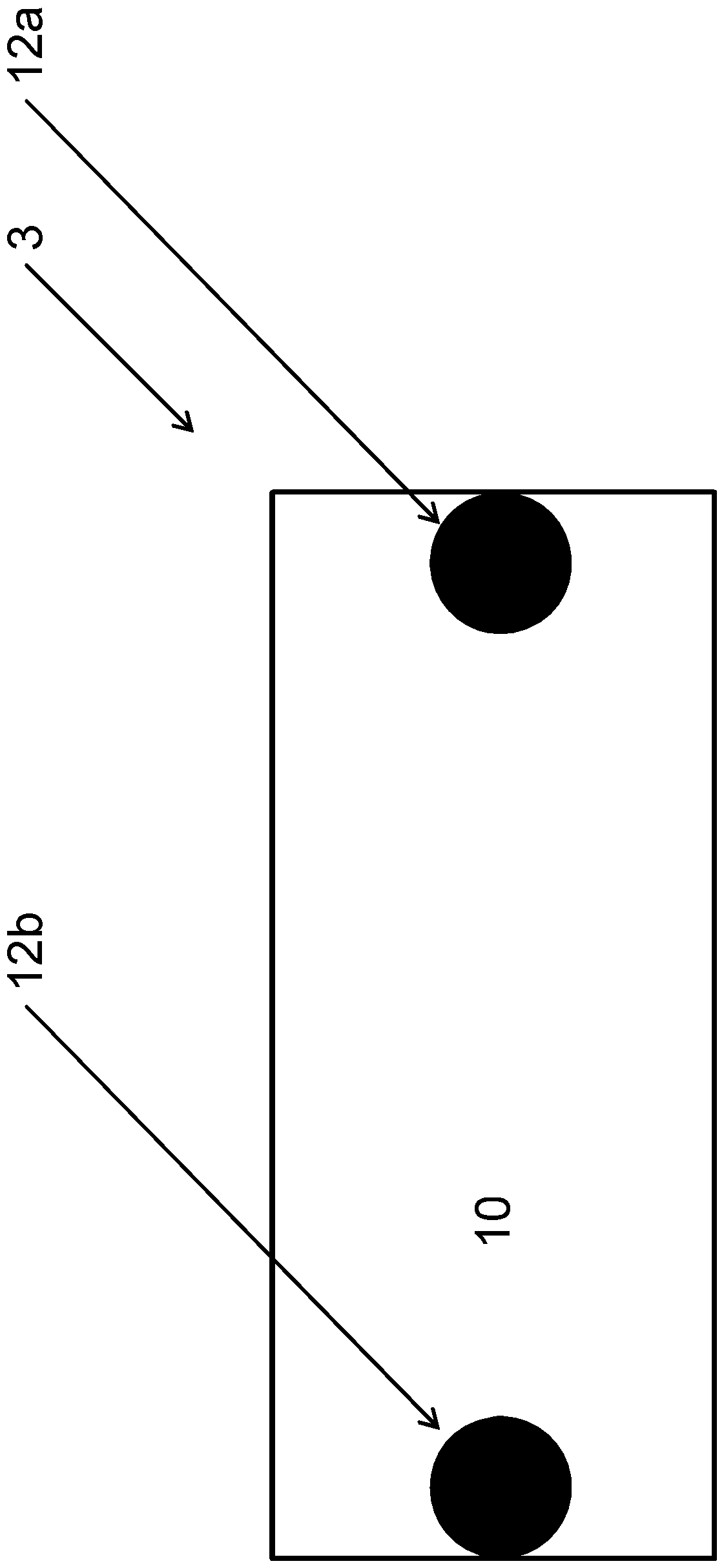

[0029] figure 1 The valve element of the valve is shown. For this purpose, the housing of the valve is provided with a flange 1 . The fixed disk 2 is arranged adjacent to the flange 1 . The fixed plate 2 is made of ceramics, preferably engineering ceramics, still more preferably aluminum oxide (Al 2 o 3 ) and / or silicon carbide (SiC) and / or zirconium dioxide (ZrO 2 ) and / or magnesium oxide (MgO). The skilled person selects a ceramic material such as alumina with a suitable level of purity such as 92%, 96% or 99%. Higher levels of purity confer advantages in terms of mechanical sealing, mechanical fragility and dielectric strength.

[0030] In alternative embodiments, the fixed disk 2 is made of a metallic material such as (stainl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com