Manufacturing method of thermoplastic film

A thermoplastic film, thermal relaxation technology, applied in the field of thermoplastic film preparation, can solve problems such as delay, achieve the effect of eliminating strain and improving dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0296] [Cellulose Acylate Resin]

[0297] In the production of cellulose acylate, sulfuric acid (7.8 parts by weight per 100 parts by weight of cellulose) was added as a catalyst, and carboxylic acid as a raw material of an acyl substituent was added, and acylation was performed at 40°C. By adjusting the type and amount of carboxylic acid added, the type and degree of substitution of the acyl group can be adjusted. After acylation, aging was performed at 40°C.

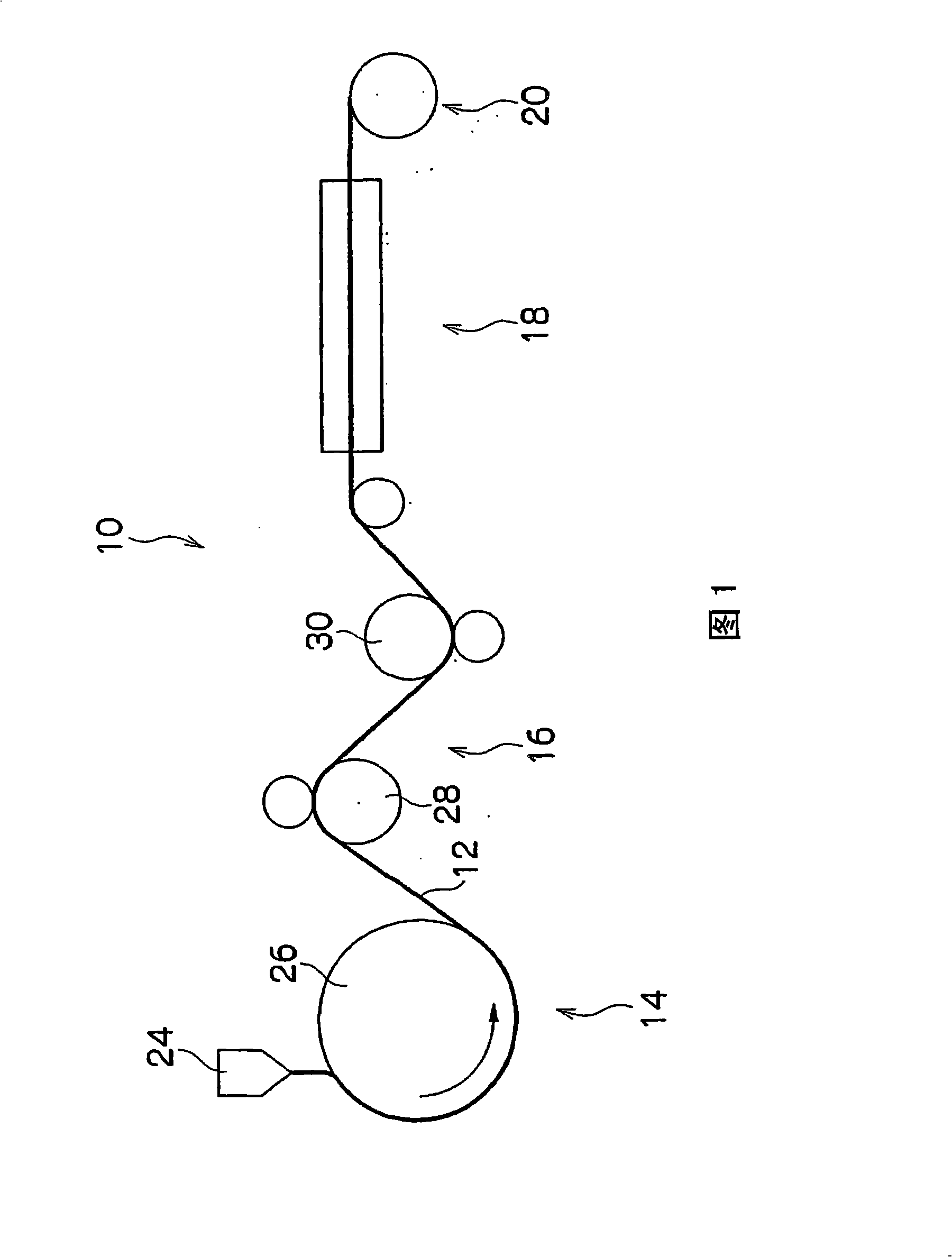

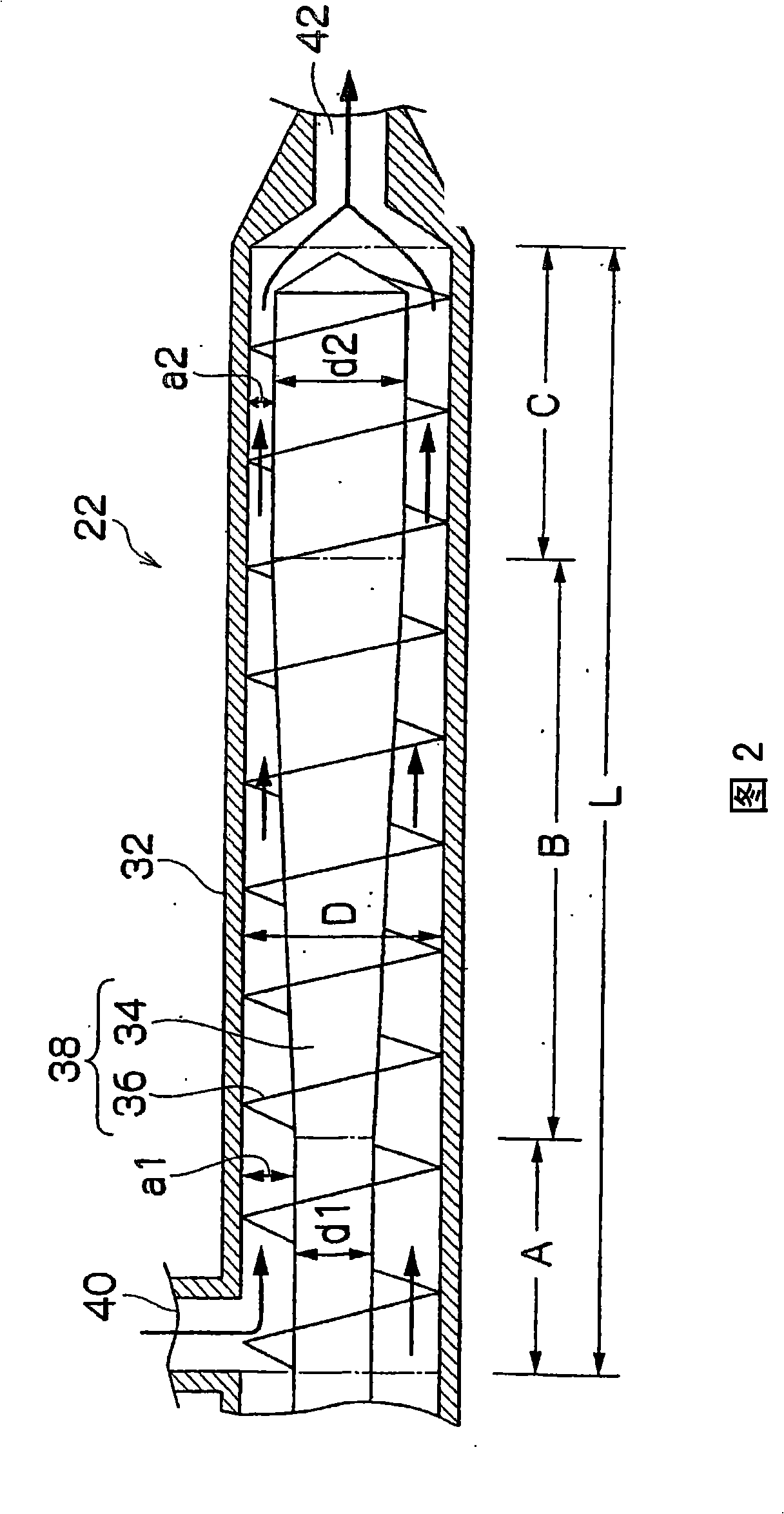

[0298] [melt film formation]

[0299] The cellulose acylate resin was formed into cylindrical pellets with a diameter of 3 mm and a length of 5 mm. In this operation, a plasticizer is selected from those described below, and kneaded into the pellets. The pellets were dried in a vacuum dryer at 110°C so that their moisture content was 0.1% or less, and after adjusting their temperature to Tg - 10°C, they were fed into a hopper. The plasticizer is selected from the following: TPP: triphenyl phosphate, BDP: biphenyl d...

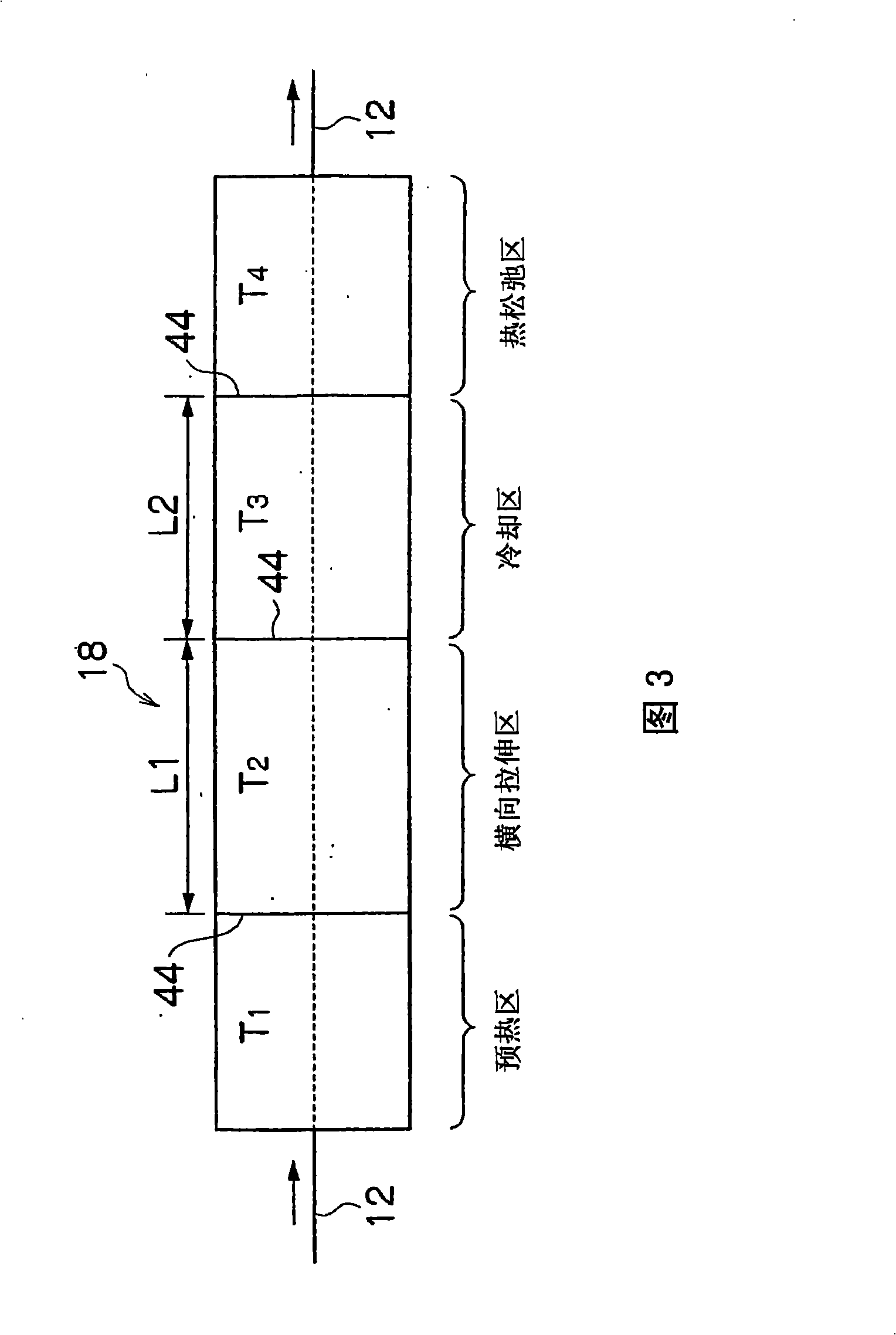

Embodiment 5

[0308]In Example 5, the temperature of the cooling zone is lower than that of the cooling zone in Example 1, and in Example 6, the temperature of the cooling zone is higher than that of the cooling zone in Example 1. Good results are always obtained even when the temperature in the cooling zone varies in the temperature range below Tg.

[0309] In Example 7, compared with those in Example 1, the degrees of substitution of the acyl groups were: A = 0.1 and B = 2.85. This confirms that even when the degree of substitution of the acyl group is varied in the ranges of 2.0≤A+B≤3.0, 0≤A≤2.0 and 1.2≤B≤2.9, in Re, Rth appear properties, percentage of dimensional change caused by heating Good results are also always obtained with respect to curved and arcuate bends. In Example 8, the degree of substitution of the acetyl group was: A=0.7, while the degrees of substitution of the propionyl, butyryl, pentanoyl and hexanoyl groups were each 0.5, and their sum was 2.0. This confirms that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com