A flue gas circulation incinerator and its incineration method

A technology of flue gas circulation and incinerator, applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problems of reducing the processing capacity of the incinerator, high investment cost of infrastructure, and insufficient combustion, so as to reduce energy loss and increase temperature , The effect of sufficient material combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

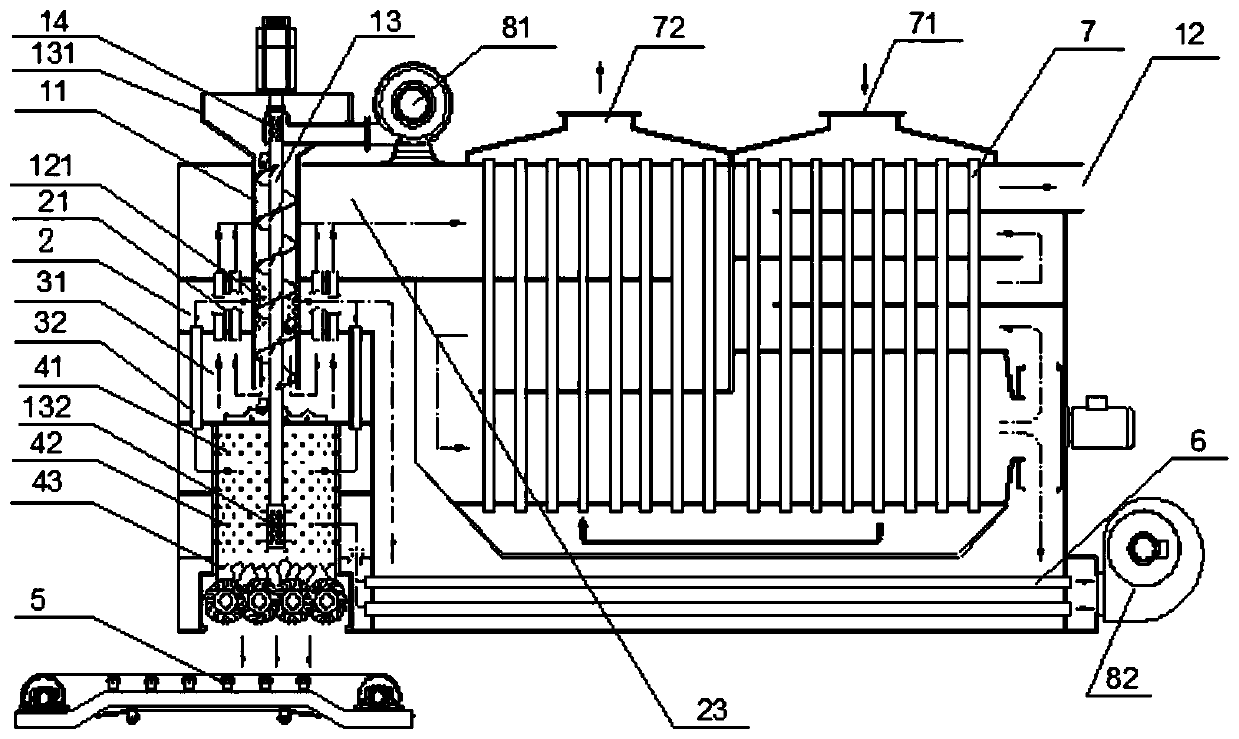

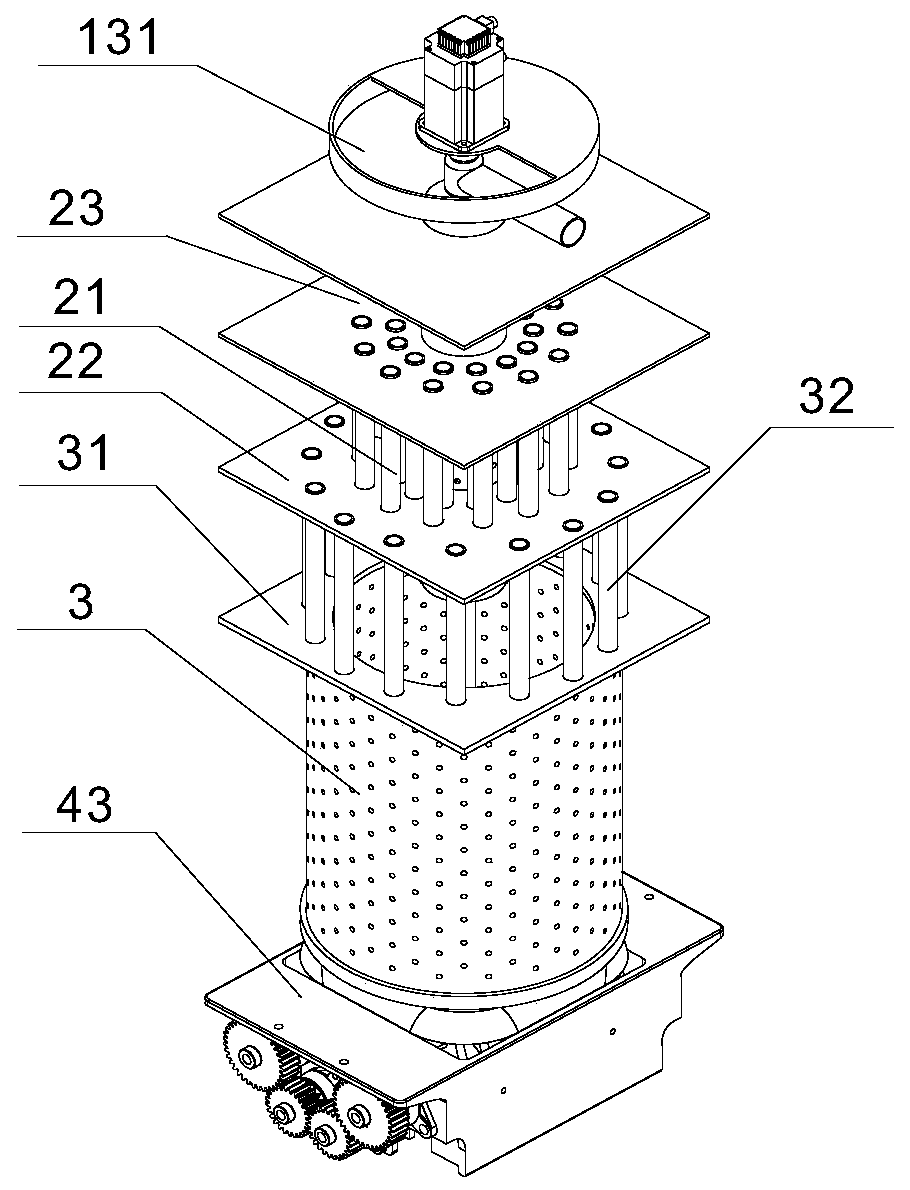

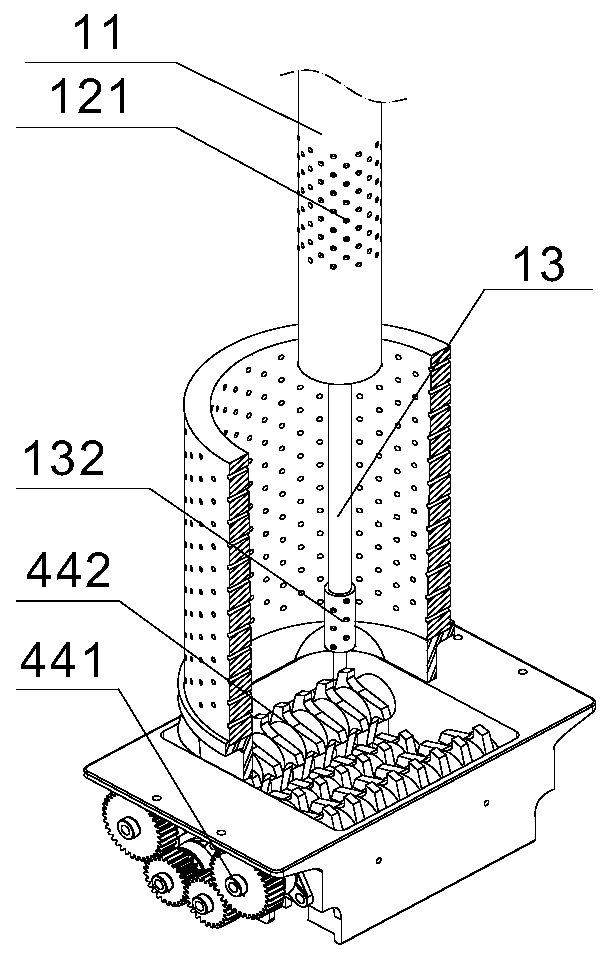

[0035] Such as Figure 1-Figure 4 As shown, the flue gas circulation incinerator provided by the present invention includes a feed system, a flue gas circulation system and a furnace 3 .

[0036]Wherein, the flue gas circulation system includes a first heat exchanger 2 , a second heat exchanger 7 and a third heat exchanger 6 . The first heat exchanger 2 and the feeding system are located on the upper part of the furnace 3, the feeding system is used to supply the dried material to the furnace 3; the first heat exchanger 2 is used to exchange between the flue gas generated by combustion and the circulating flue gas The heat and preheat the material in the feeding system. The feed system passes through the first heat exchanger 2, and the material in it is heated to 150-300°C, such as 200°C, 250°C, etc., through the first heat exchanger 2 during the process of falling into the furnace 3.

[0037] A third chamber 31 is also provided between the first heat exchanger 2 and the fur...

Embodiment 2

[0070] Such as Figure 5As shown, the flue gas circulation incinerator provided by the present invention includes a feed system, a flue gas circulation system and a furnace 3 .

[0071] Wherein, the flue gas circulation system includes a first heat exchanger 2 , a second heat exchanger 7 and a third heat exchanger 6 . The first heat exchanger 2 and the feeding system are located on the upper part of the furnace 3, the feeding system is used to supply the dried material to the furnace 3; the first heat exchanger 2 is used to exchange between the flue gas generated by combustion and the circulating flue gas of heat. The feed system passes through the first heat exchanger 2, and the material in it is heated to 150-300°C, such as 200°C, 250°C, etc., through the first heat exchanger 2 during the process of falling into the furnace 3.

[0072] The flue gas cooled by the first heat exchanger 2 enters the second heat exchanger 7 for further cooling, part of the flue gas leaves the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com