Radial/axial 360° along-way wellbore wax deposition evaluation method and imaging method

An imaging method and evaluation method technology, applied to measuring devices, using ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of inability to provide wax deposition data, low calculation accuracy, and difficulty in controlling the accuracy of results, etc., to achieve The parameter setting process is simple and easy, the visualization effect is good, and the display result is intuitive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

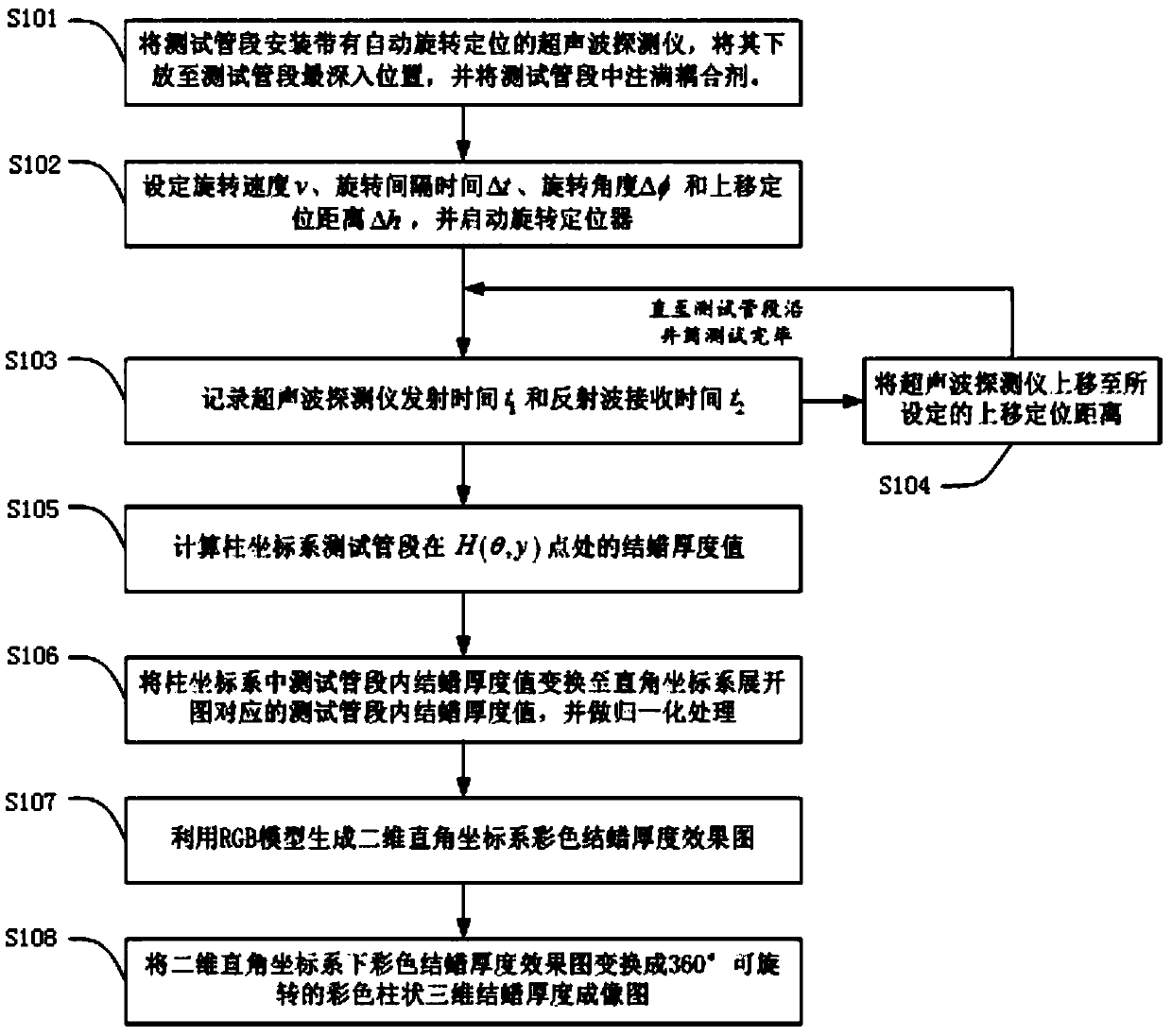

[0048] The present invention will be further described below in conjunction with the accompanying drawings.

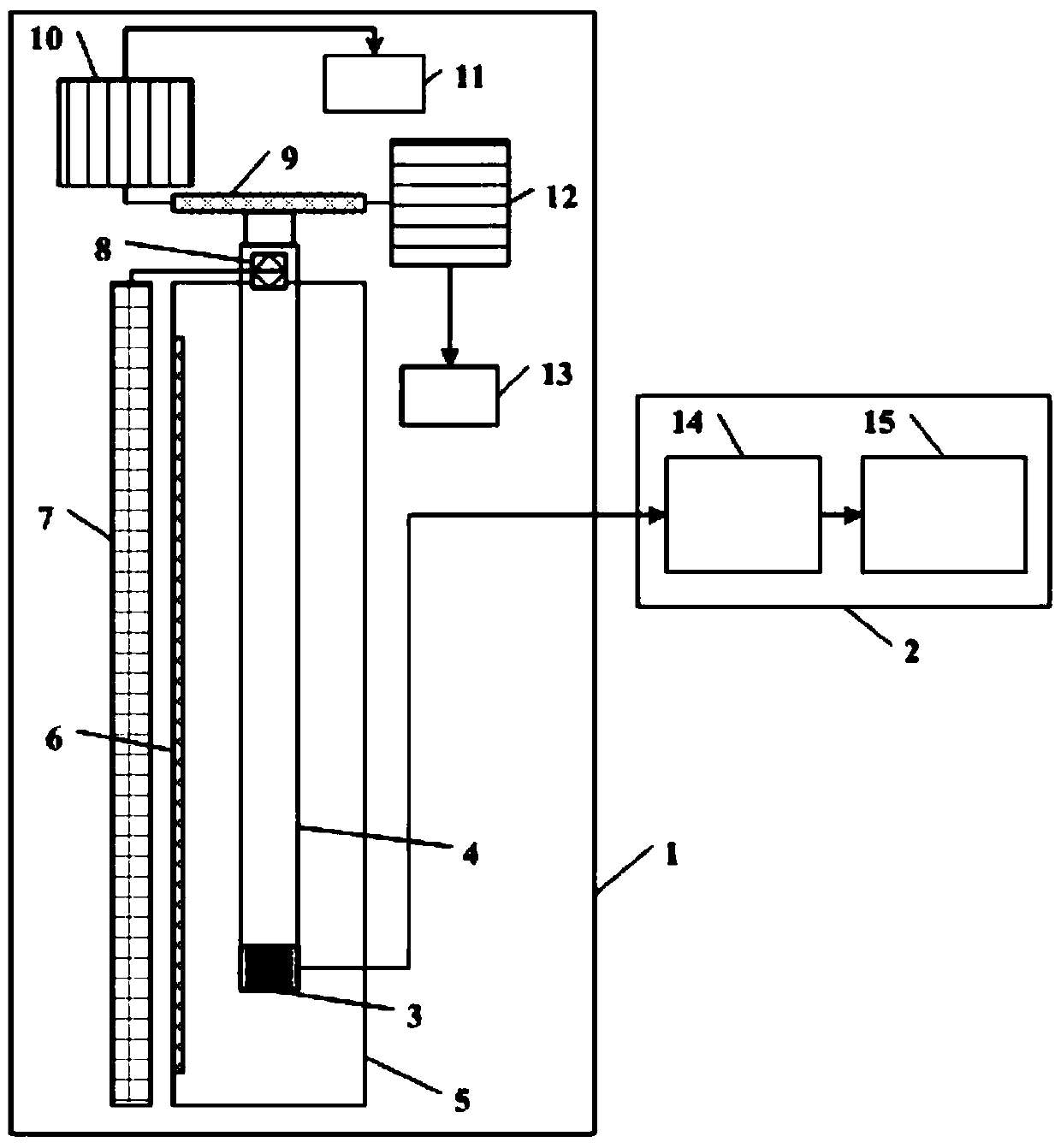

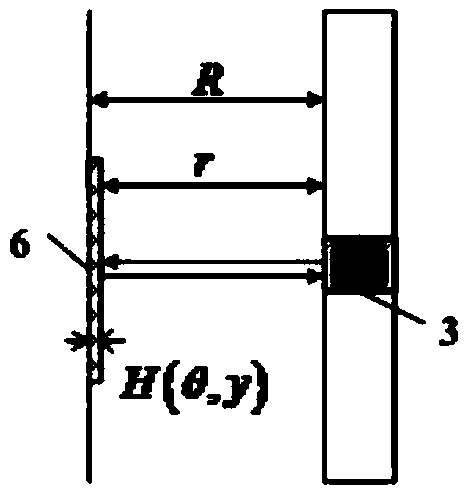

[0049] as attached figure 1 As shown, a radial / axial 360° along-way wellbore wax measurement and imaging device includes an ultrasonic detector measurement unit 1 and a measurement data imaging processing unit 2 for measuring the wax deposition layer 6 on the oil pipe 5 in the wellbore The distribution of wax deposition thickness along the radial and axial directions.

[0050] The ultrasonic probe measuring unit 1 includes a rotating test rod 4 extending into the oil pipe 5 to be tested, an ultrasonic probe 3 arranged at the lower end of the rotating test rod 4, and a rotating mechanism 9 arranged at the upper end of the rotating test rod 4 ; The ultrasonic detector 3 is used to measure the ultrasonic emission time t 1 and the reflected wave receiving time t 2 , so that the measurement data processing system 14 in the measurement data imaging processing unit 2 deter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com