Corridor pipe GIL (Gas Insulated Line) three-dimensional temperature field and expansion and shrinkage deformation calculation method based on workbench

A technology of three-dimensional temperature and calculation method, which is applied in calculation, computer-aided design, design optimization/simulation, etc., and can solve problems such as the temperature distribution of GIL pipelines that cannot be considered

Active Publication Date: 2018-05-18

XI AN JIAOTONG UNIV +3

View PDF4 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Moreover, the above two finite element methods cannot consider the temperature distribution of the GIL pipeline under the condition of wind speed

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

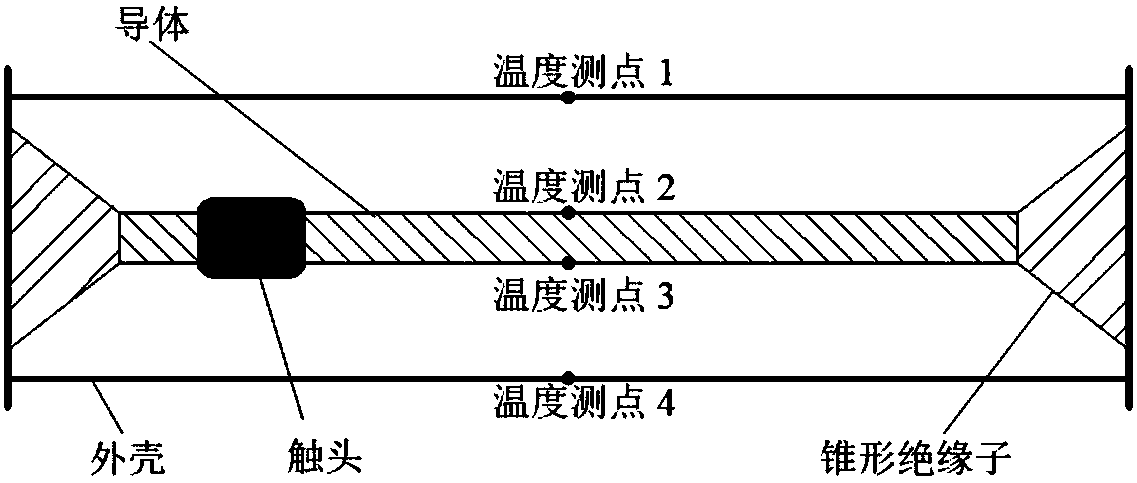

[0126] According to the method proposed by the present invention, the experiments of people such as Minaguchi are simulated and calculated, and the experimental model is as figure 2 Shown:

[0127] The conductor and shell size parameters are as follows:

[0128]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

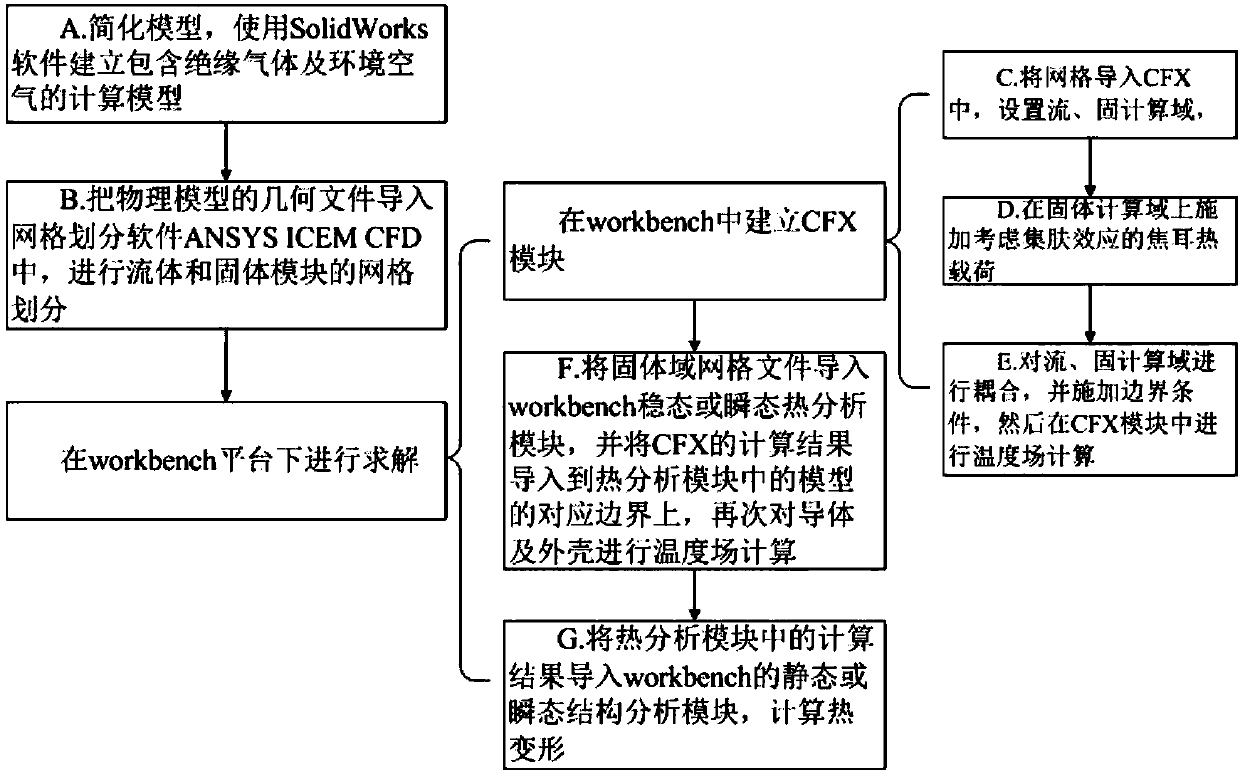

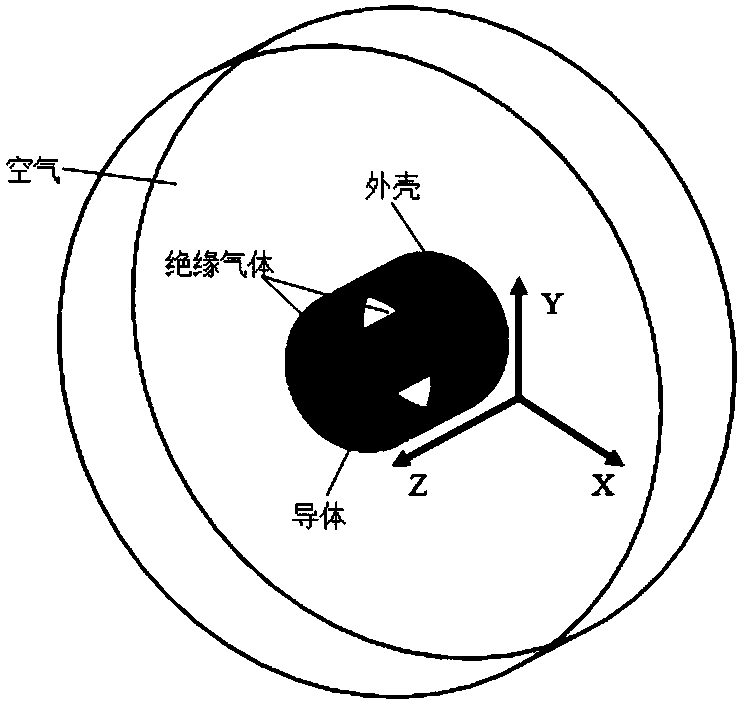

The invention discloses a corridor pipe GIL (Gas Insulated Line) three-dimensional temperature field and expansion and shrinkage deformation calculation method based on a workbench. According to the structural characteristics of corridor pipe GIL arrangement, an electrical heat multi-physics coupling calculation model under an integral GIL environment is established in the workbench, a GIL three-dimensional temperature field is obtained through calculation according to a corresponding operation working condition, and a finite element method is used for obtaining corresponding GIL expansion andshrinkage deformation data in the workbench. The calculation method can provide a basic reference for the selection and the screening of corridor pipe GIL elements, based on the operation basic parameters, the theoretical data of the temperature and the expansion and shrinkage deformation in a GIL operation process is calculated, and a technical support is provided for system operation state evaluation. According to the method, the temperature field of a gas insulation electric transmission line can be accurately calculated, in addition, applied load and boundary conditions can be changed forcarrying out simulation calculation on the gas insulation electric transmission line temperature field under various different operation conditions, meanwhile, the thermal deformation of the GIL pipeline can be calculated, and the method has a reference meaning for the structure design and operation condition of the gas insulation electric transmission line.

Description

technical field [0001] The invention relates to the technical field of UHV gas-insulated power transmission, in particular to a workbench-based three-dimensional temperature field and expansion-contraction deformation calculation method of a GIL. Background technique [0002] Gas insulated transmission line (GIL) has the advantages of high voltage level, large transmission capacity, low power loss, and small electromagnetic interference, and has great advantages in areas where traditional overhead lines are restricted, such as crossing straits, rivers and seas, etc. Therefore GIL will be widely used. [0003] During operation, due to Joule heat loss, the transmission line is always in a state of heating, resulting in an increase in line temperature. The temperature rise not only reduces the maximum current-carrying capacity of the line, but also affects the insulation performance of the internal non-conductive material when the temperature exceeds a certain limit, reduces t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G06F17/50

CPCG06F30/23G06F2113/16

Inventor 徐亮张高爽龙艳高建民李云龙王荣喜

Owner XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com