Piezoelectric ceramic actuator steering engine servo mechanism and steering engine servo method

A technology of piezoelectric actuators and piezoelectric ceramics, applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve the problem of inability to realize aeroelastic servo control and response Frequency reduction and other issues, to achieve the effect of increasing control frequency, high response speed, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

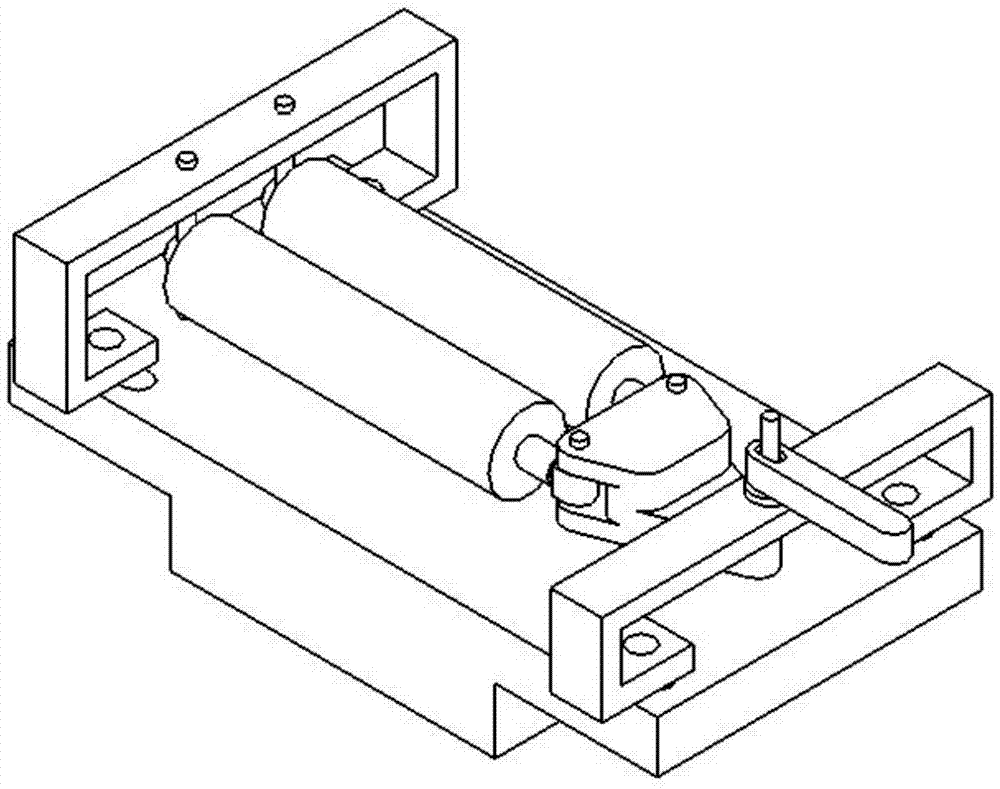

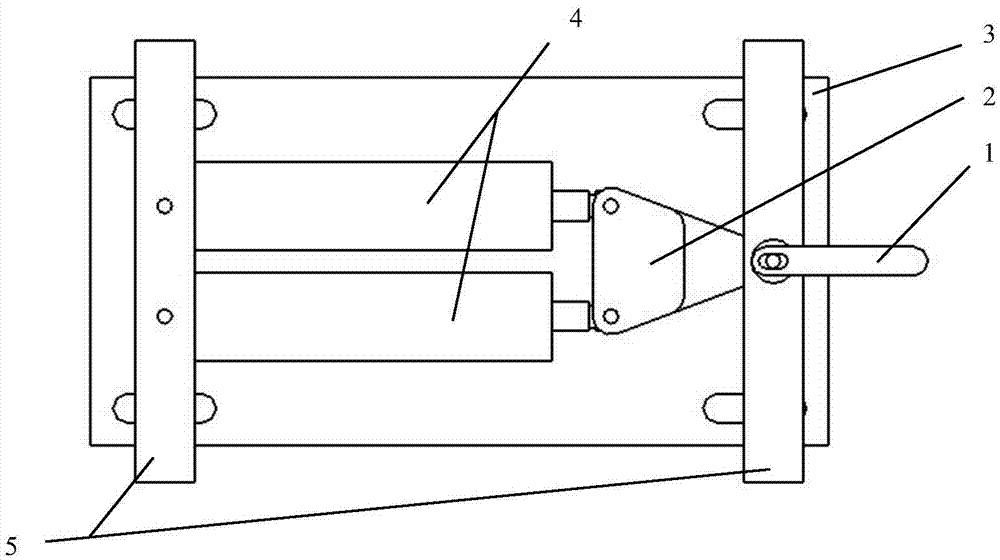

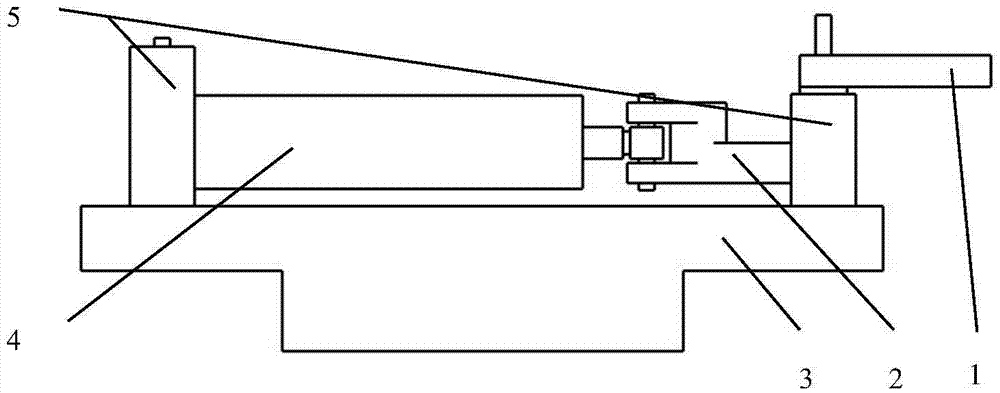

[0018] Aiming at the problem that the steering gear on the unmanned aerial vehicle in the prior art is difficult to achieve reasonable aeroelastic servo control, the inventor has conducted research; the inventor considers that piezoelectric ceramics are a function that can convert mechanical energy and electrical energy into each other Ceramic material. Piezoelectric ceramic materials have stable chemical properties and are not affected by moisture and other atmospheric conditions. Piezoelectric ceramics can be made into any shape and size, and the polarization direction can be freely selected, which has strong adaptability. Because the material is very hard, it has a great load-bearing capacity. Piezoelectric ceramics have been widely used in high-precision optoelectronic instruments, micro-robots and other fields, and their control accuracy reaches the nanometer level.

[0019] On the basis of considering the actuating frequency and output characteristics of the piezoelectr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com