Needle cap suitable for syringe

A needle cap and cap body technology, applied in the field of medical devices, can solve the problems of meaningless waste of medicine and affecting the treatment effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

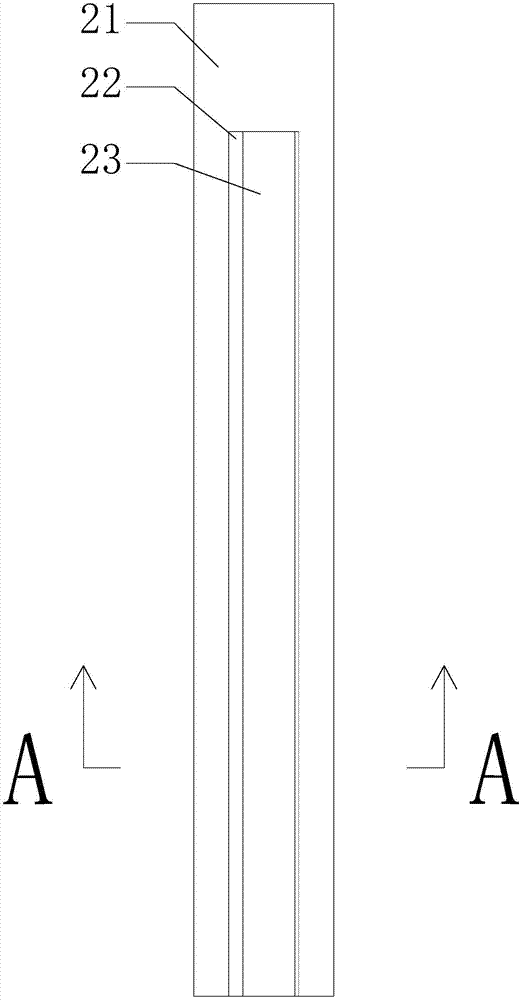

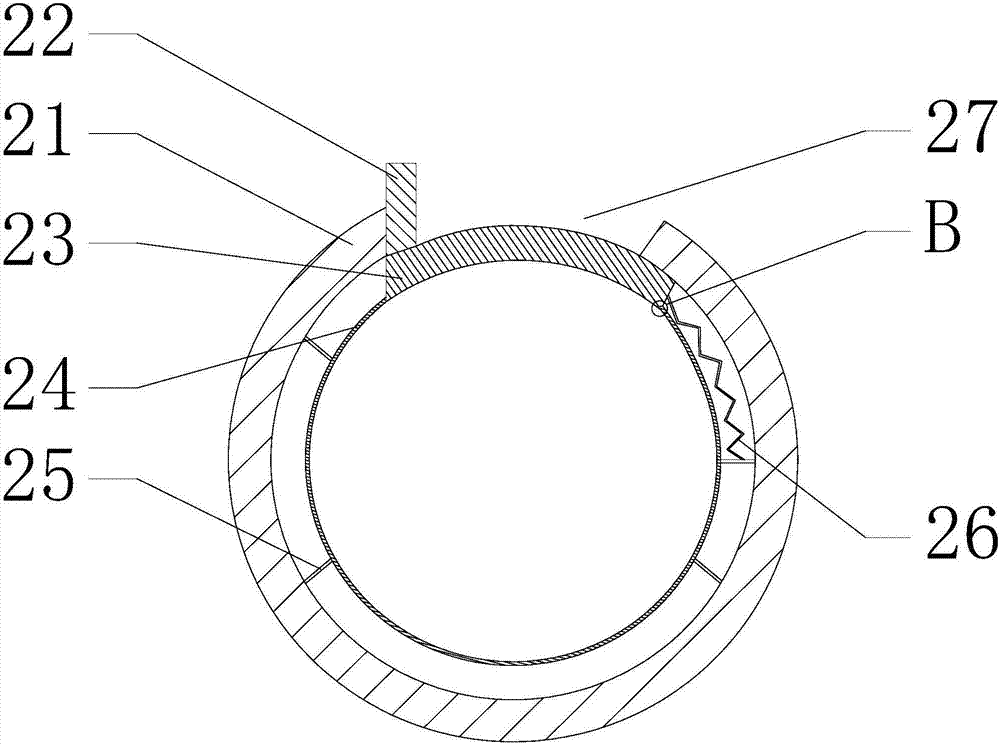

[0039] Embodiment: a kind of needle cap that is applicable to syringe, its structure is as Figure 2-6 shown, including:

[0040] The cap body 21, the cap body 21 is a hollow cylindrical structure;

[0041] The top of the cap body 21 is a closed structure, and the bottom is an open structure;

[0042] The side of the cap body 21 has a first through groove 27;

[0043] The inner wall of the cap body 21 is fixedly connected with the sleeve 24 through four connecting plates 25;

[0044] The top of the sleeve 24 is a closed structure, and the bottom is an open structure;

[0045] The side of the sleeve 24 has a second through groove 28;

[0046] The first through-slot 27 and the second through-slot 28 together become a channel for the needle piercing part to enter the inside of the cap body 21 .

[0047] An arc-shaped baffle 23 for closing the first through groove 27 is arranged between the sleeve 24 and the cap body 21, and one side (exposed side) of the arc-shaped baffle 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com