Automatic installation system for transformer magnetic ring shell

An automatic installation and transformer technology, applied in assembly machines, metal processing equipment, metal processing, etc., can solve the problems of restricting production efficiency, difficulty in meeting the needs of mass production, and prone to slag in magnetic ring coils, so as to avoid jamming The effect of reducing the risk of injury and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

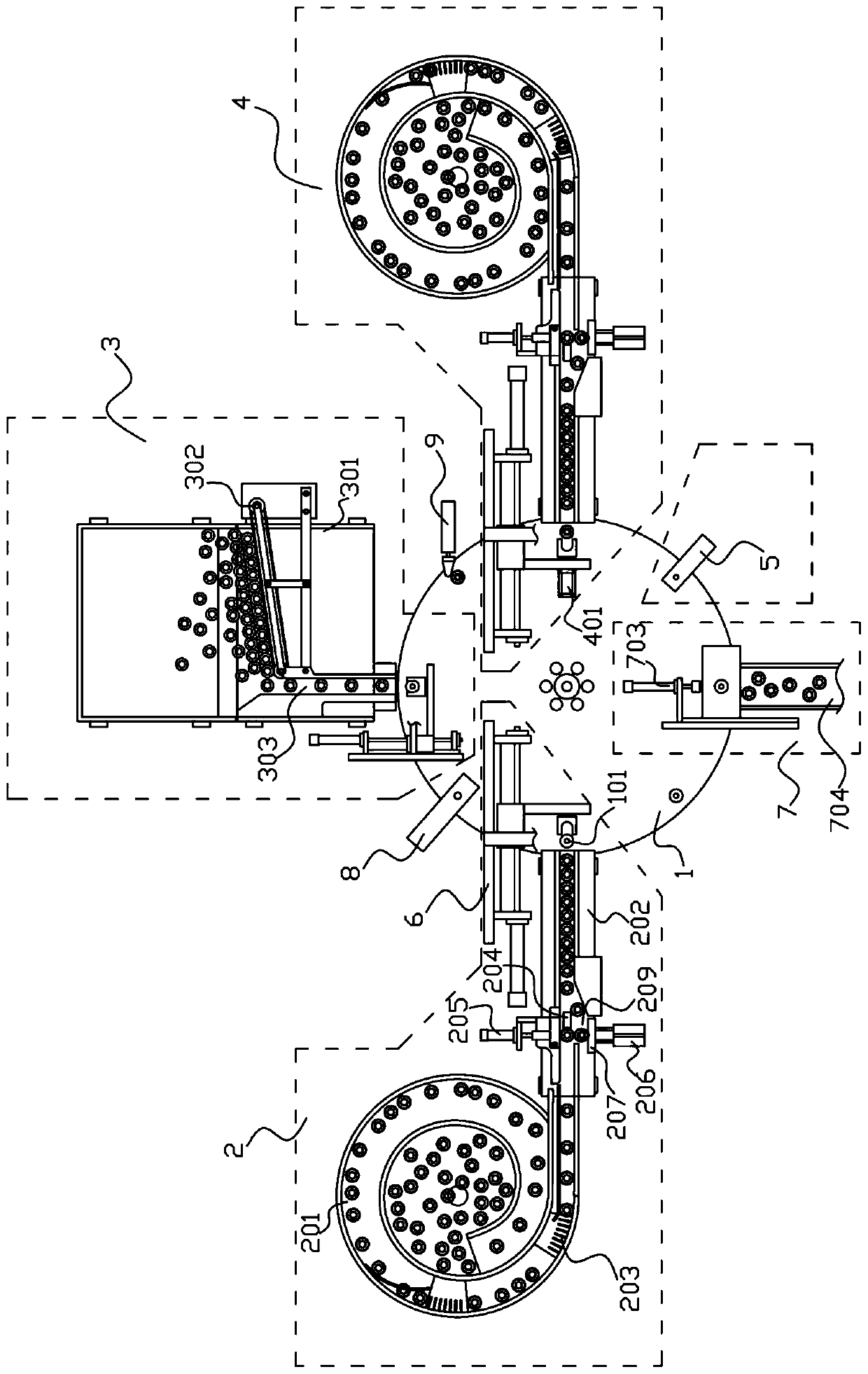

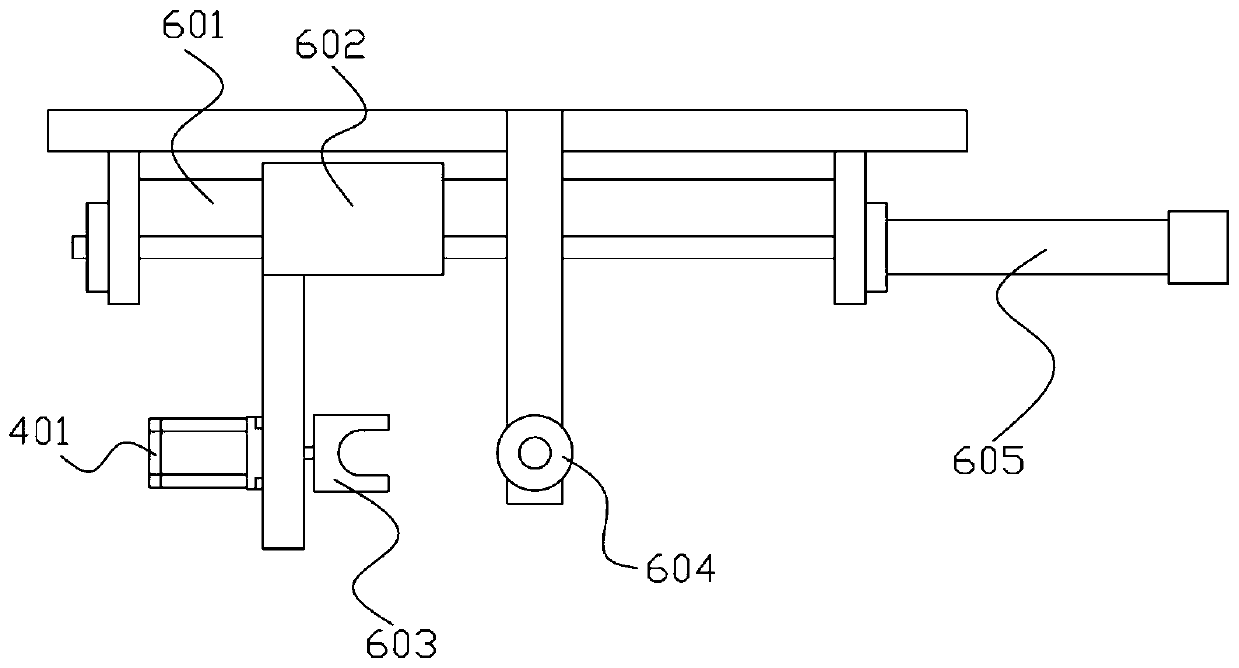

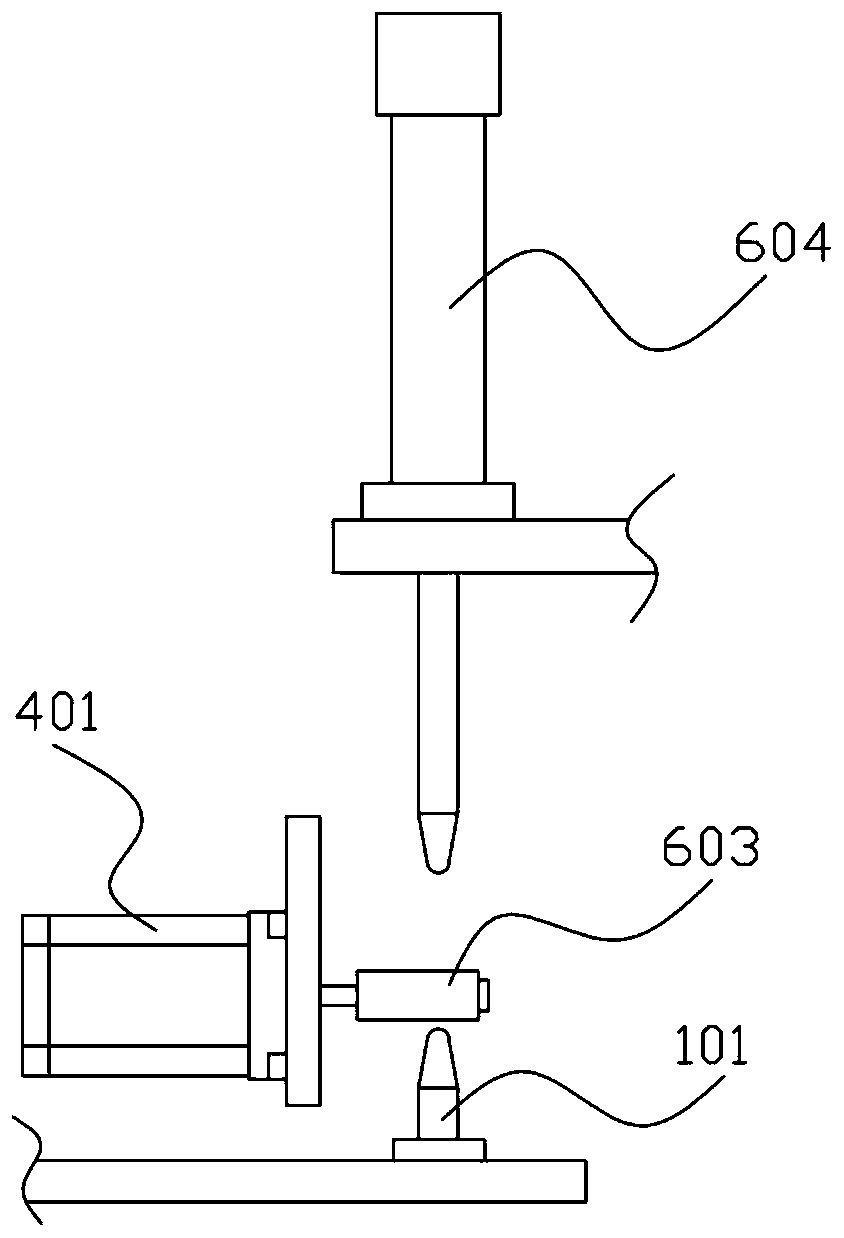

[0036] Specific examples figure 1 As shown, the present invention is an automatic installation system for the magnetic ring shell of a transformer, which includes an assembly tray 1 and feeding equipment around the side of the assembly tray 1. The lower cover feeding device 2, the magnetic ring feeding device 3, the upper cover feeding device 4, the assembly crimping device 5 and the discharge device 7, a group of limit posts 101 are arranged on the disk surface of the assembly disk 1, and the feeding equipment follows the The rotation of the assembly plate 1 puts the lower cover, the magnetic ring coil and the upper cover on the limit post 101 in turn, and assembles and crimps to form a fastened whole, so that the limit post 101 passes through the feeding equipment in turn with the rotation of the assembly plate 1 And complete the magnetic ring ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com