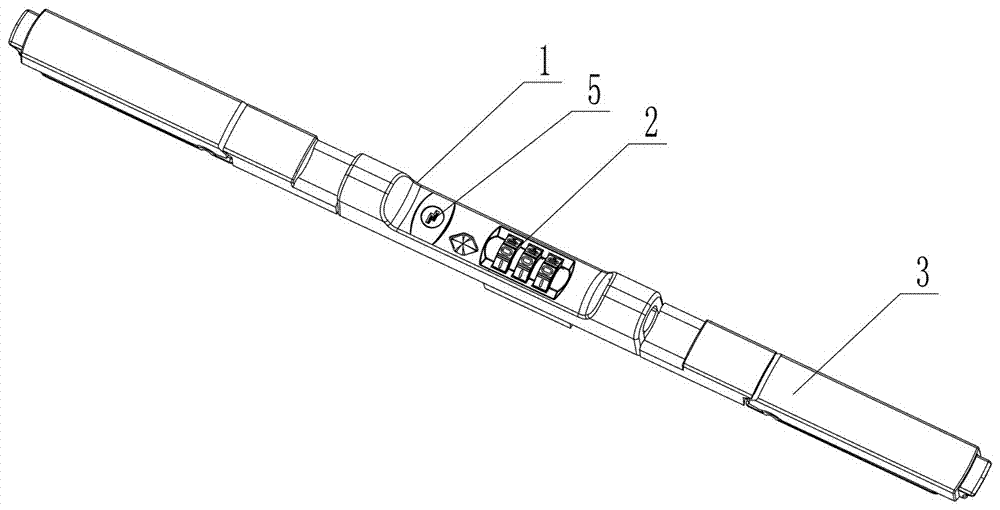

Double-channel luggage central control lock

A dual-channel, luggage technology, applied in building locks, buildings, building structures, etc., can solve problems such as low structural reliability, unreliability, and difficult production and installation, and achieve simple and reliable structure, small effective length, and space saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

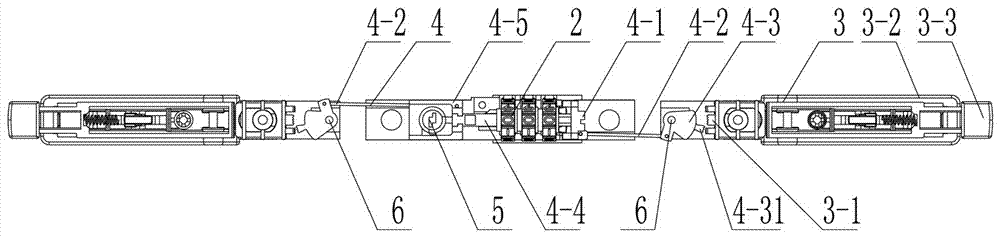

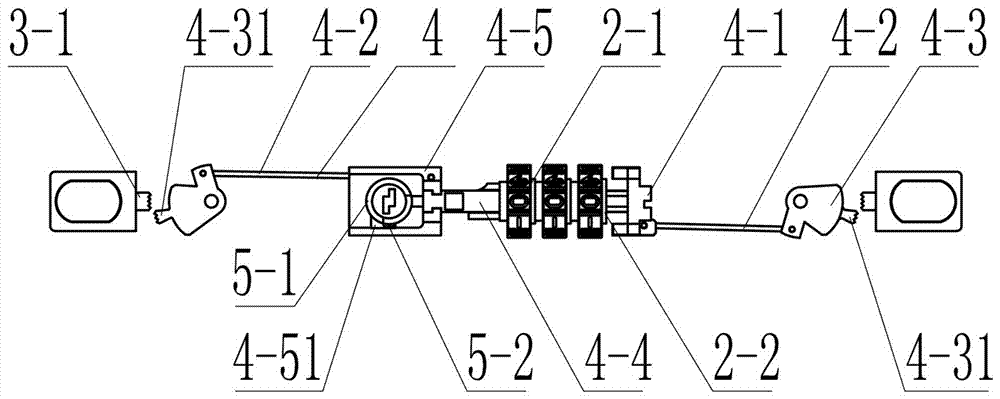

[0022] Such as Figure 1-10 As shown, a dual-channel luggage central control lock provided by the present invention includes a lock case 1, a central control lock group 2, a customs lock group 5, a side lock 3 and a linkage mechanism 4, a central control lock group 2 and a customs lock group 5 At the same time, when locking, the side lock 3 is restricted by the linkage mechanism 4, and when the central control lock group 2 or the customs lock group 5 is opened, the restriction on the side lock 3 is released by the linkage mechanism 4. The linkage mechanism 4 includes a left connector 4-5. , the right connector 4-1, the left and right transmission connecting rods 4-2, the left and right limit blocks 4-3 and the lock bar 4-4, the lock bar 4-4 cooperates with the central control lock group 2, and with the central control The lock group 2 is opened and locked to move left and right, the left connector 4-5 and the right connector 4-1 are respectively connected to the two ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com