Cartesian optical assembly assembling and tuning method

A technology for optical components and assembling and adjusting methods, applied in optical components, optics, installation and other directions, can solve the problem of high accuracy of assembly and adjustment, and achieve the effect of ensuring symmetry and reducing processing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further elaborated below by describing a preferred specific example in detail in conjunction with the accompanying drawings.

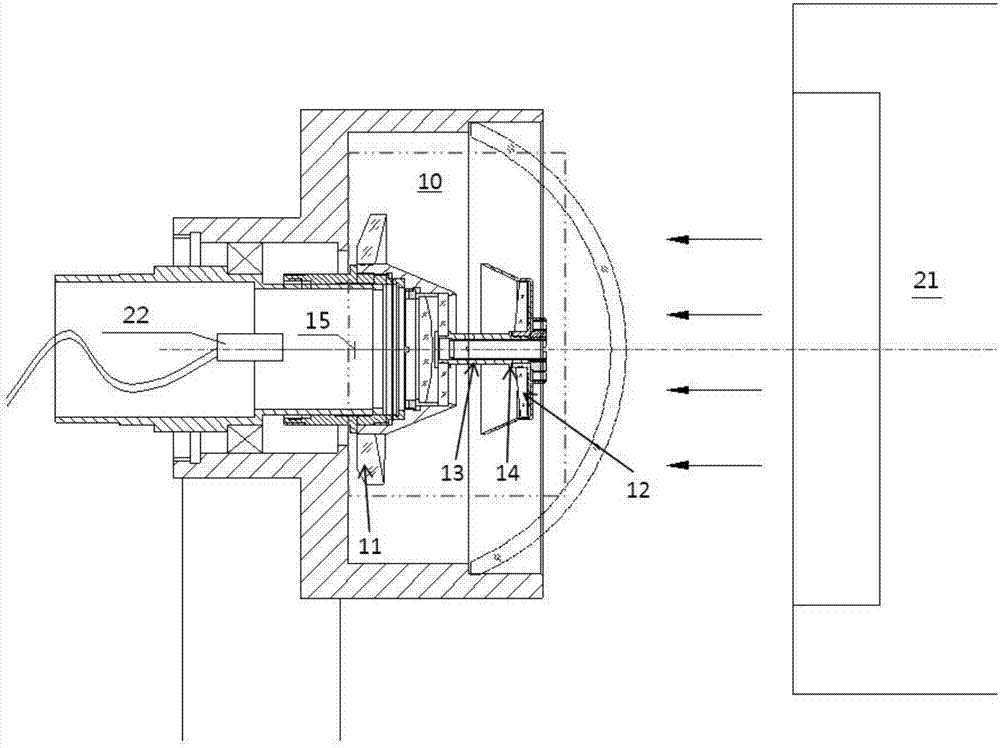

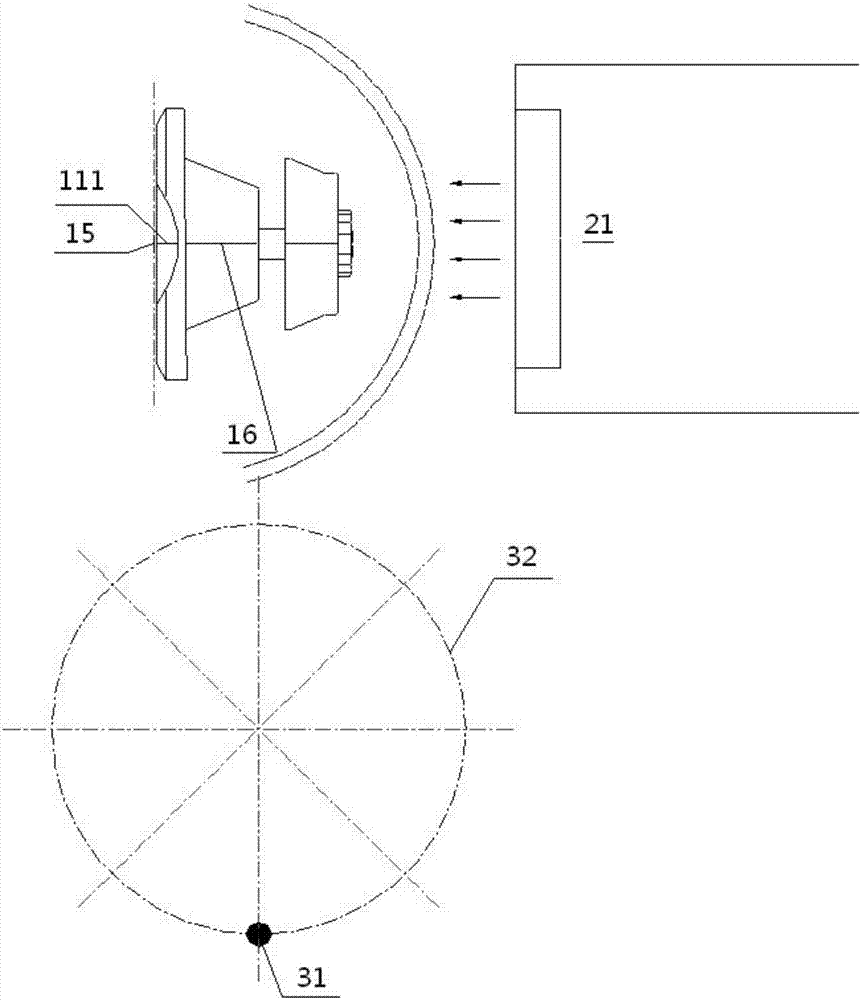

[0034] like figure 1 As shown, it is a schematic diagram of the debugging device of the present invention; the part inside the dotted line box is the Karl Fischer optical assembly 10 . The debugging equipment includes an infrared collimator 21 and a detection system capable of measuring the size of the spot and the diameter of the scanning circle, which can display the conditions of the spot and the scanning circle in real time. Among them, the spot 31 is formed by the infrared energy detected by the Karl Fischer optical component 10, and the scanning circle 32 is formed by the rotation of the Karl Fischer optical component 10 around the central axis. Both are detected by the detection system and displayed on the screen.

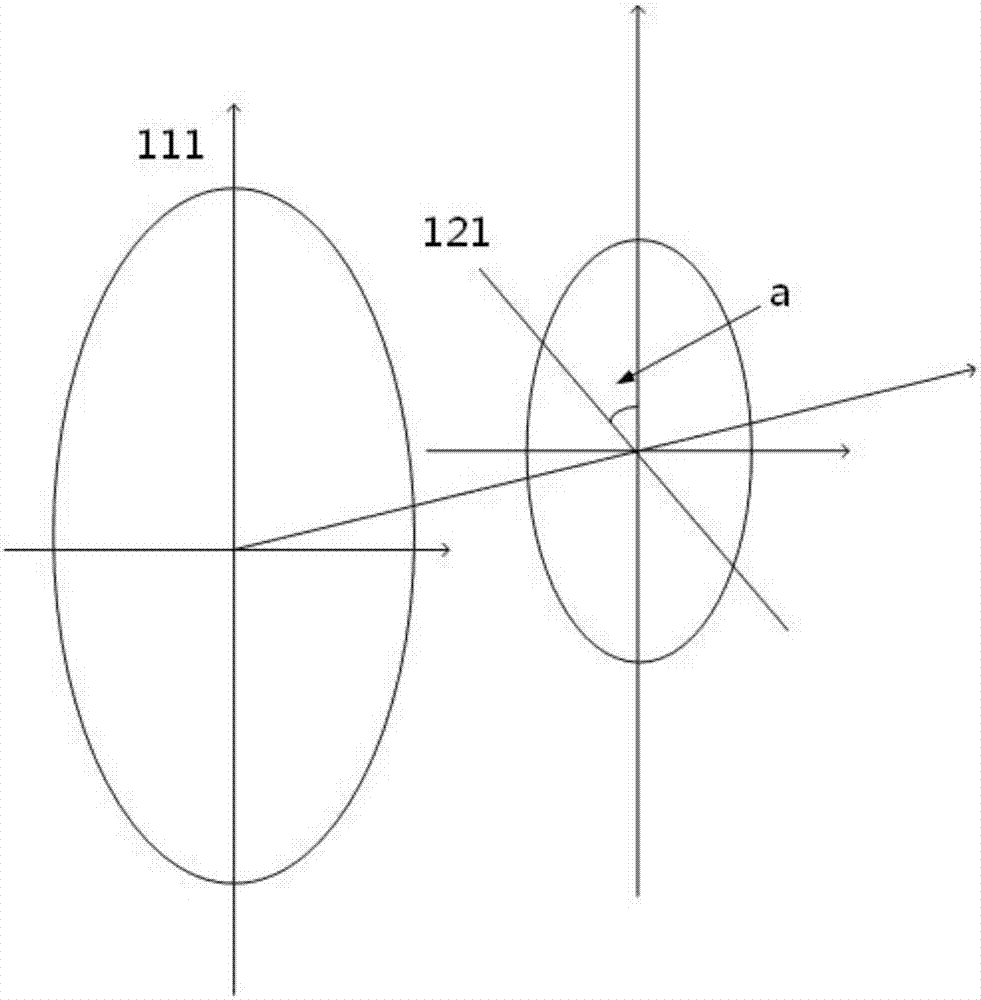

[0035] Specifically, the Karl Fischer optical assembly 10 receives the infrared parallel ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com