High-flux combined material heat treatment system and heat treatment and detecting method thereof

A heat treatment system and a technology for combining materials, which are applied in the high-throughput combined material heat treatment system and its heat treatment and detection fields, can solve the problems of unstable quality of micro-area sample heating, and improve the accuracy of phase transition temperature, efficient heat treatment, and high-efficiency heat treatment. Stable quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solutions and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and implementation examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

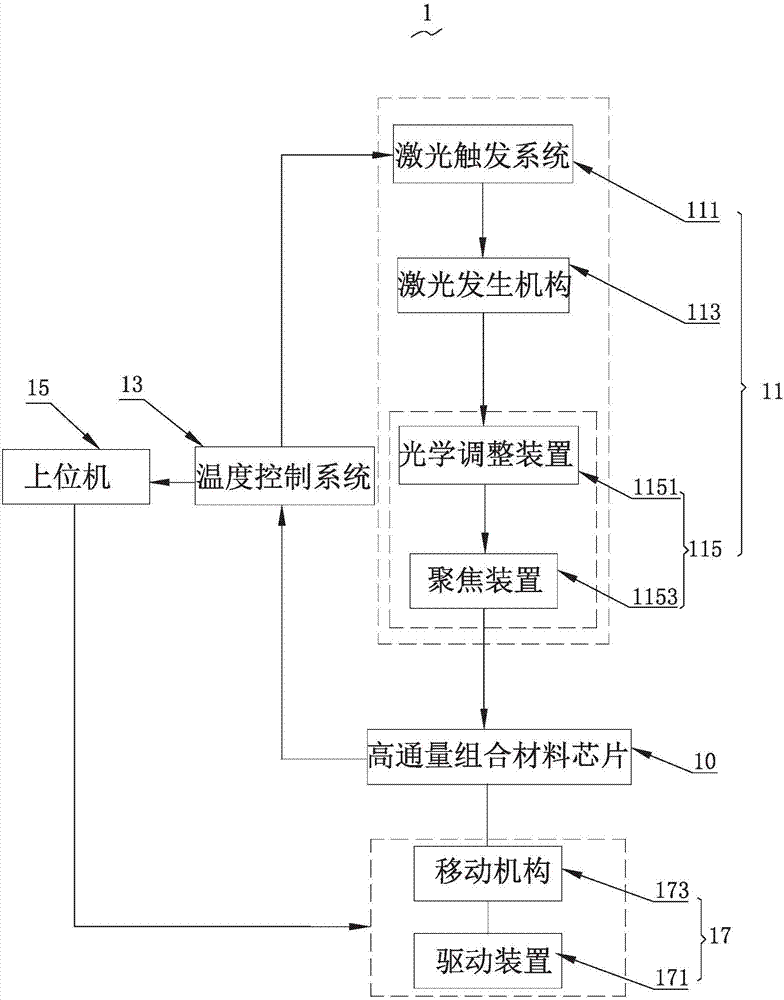

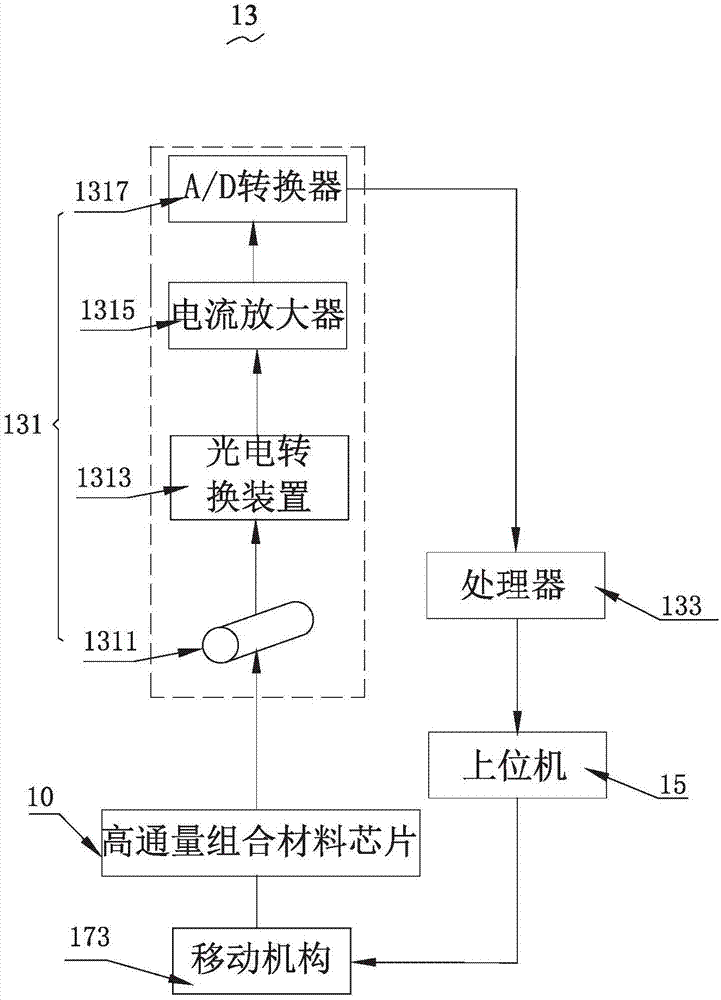

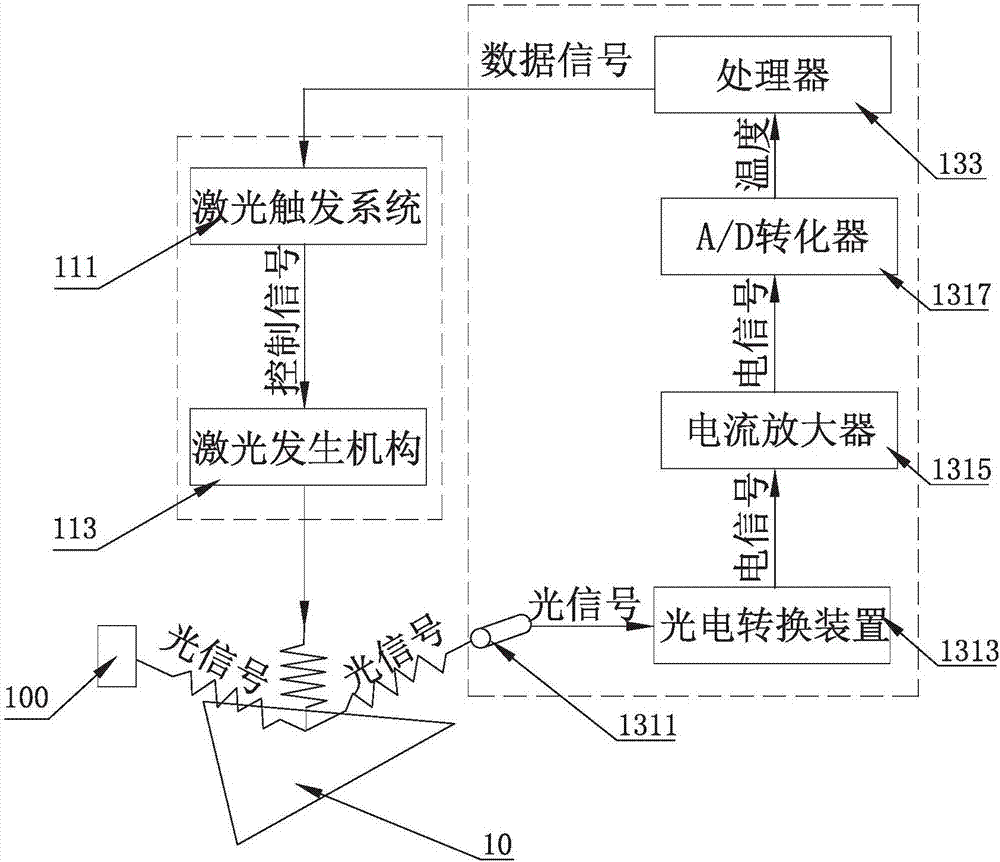

[0034] see figure 1 , the first embodiment of the present invention provides a high-throughput combined material heat treatment system 1, the high-throughput combined material heat treatment system 1 is used to heat-treat the high-throughput combined material chip 10, and the high-throughput combined material chip 10 includes multiple domain samples of different compositional materials. The high-throughput combined material heat treatment system 1 includes a laser heating system 11 , a temperature control system 13 , a host computer 15 and a displacement control system 17 . The h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com