Sealed fixing structure of vehicle leading up wire and sealed fixing method thereof

A technology for sealing, fixing and leading wires, applied in vehicle parts, circuits or fluid pipelines, electrical components, etc., can solve problems such as high cost, inconvenient maintenance and disassembly, poor sealing, etc., and achieve broad application prospects and economic value, The effect of convenient post-maintenance and easy post-maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

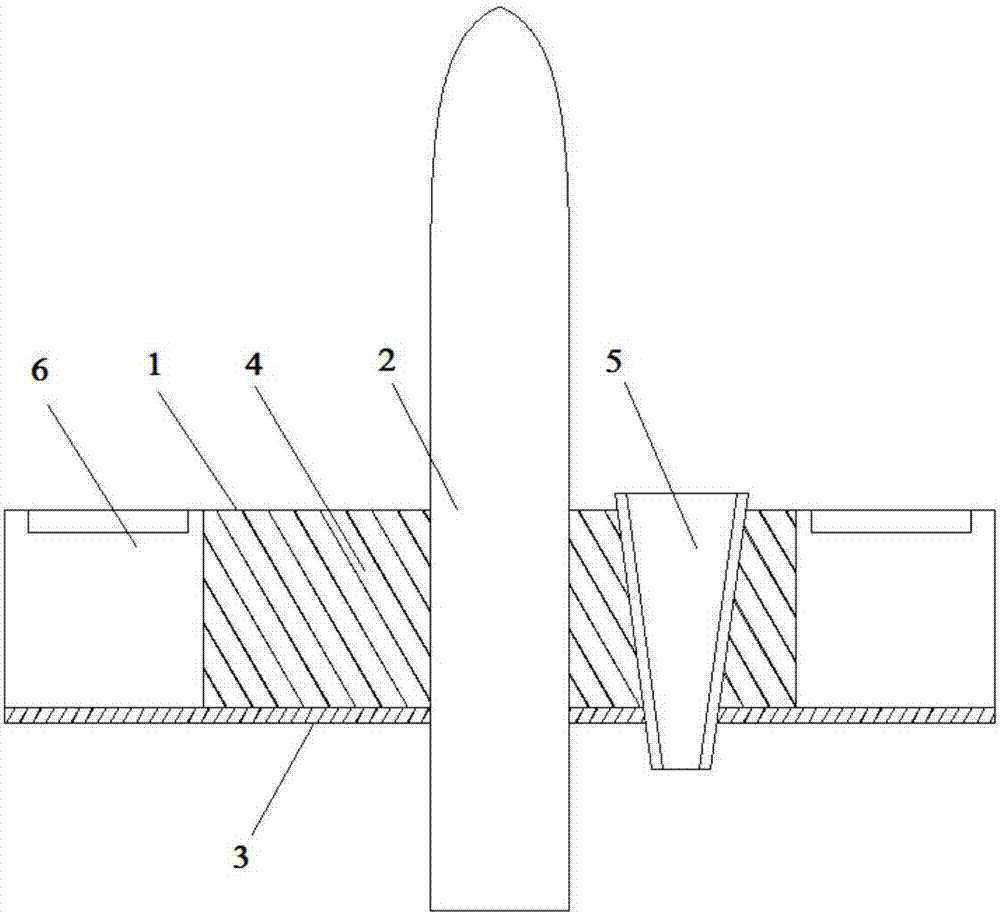

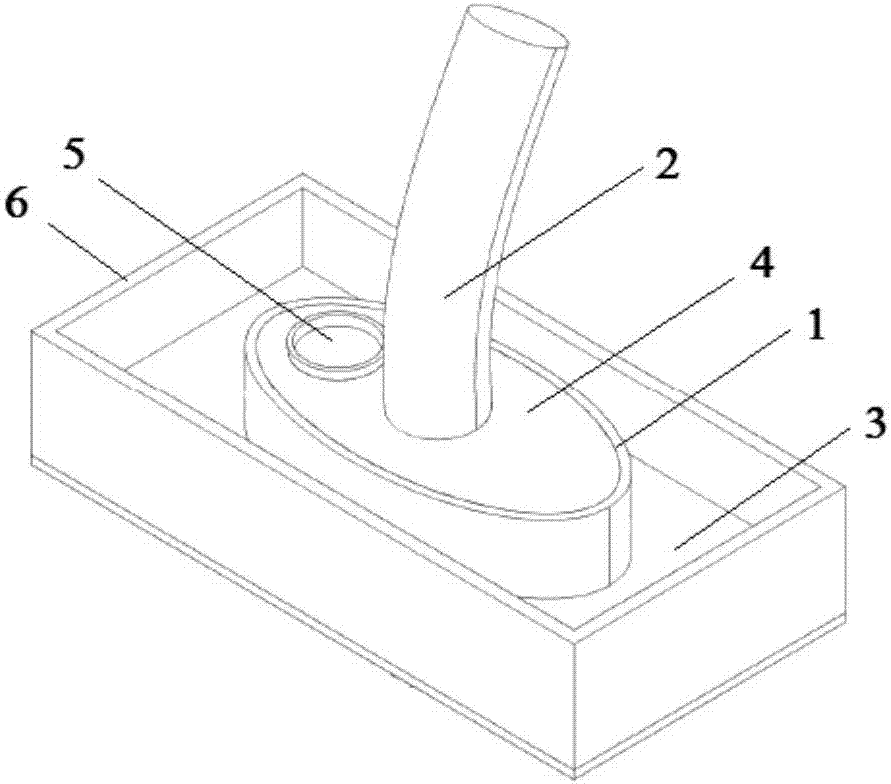

[0036] For the lead wires of vehicles in the field of automobiles and rail transit, the following processes are used for sealing and fixing:

[0037] 1. Clean the bottom of the metal frame of the lead-in hole of the vehicle body, seal the bottom of the metal frame of the lead-in hole with butyl sealing tape, and then use a narrower butyl sealing tape at the gap between the cable and the metal frame of the lead-in hole Winding is performed, thereby forming a sealing portion. When the cable in the lead-through hole is affected by external vibrations, the butyl sealing tape can be well adhered to the surface of the cable, and it is not easy to fall off from the cable to form a complete sealing system.

[0038] 2. Insert the embedded pipe, penetrate the butyl sealing tape, and expose a little, so that the position of the embedded pipe is easy to find. Pre-embedded pipes fall off during vibration.

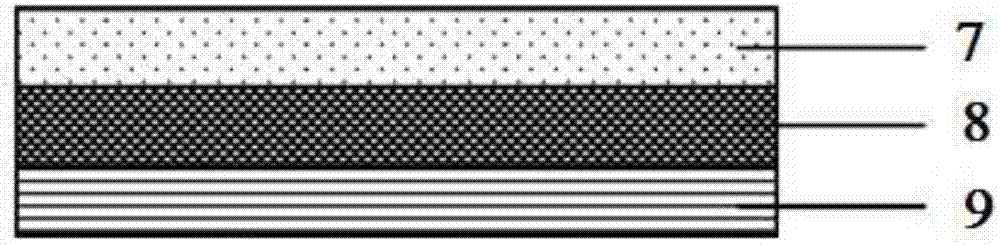

[0039] 3. Pour MF962 silicone electronic sealant (self-leveling) (purchased from Zh...

Embodiment 2

[0042] For the lead wires of vehicles in the fields of automobiles and rail transit, the following processes are used for sealing and fixing:

[0043] 1. Clean the bottom of the metal frame of the lead wire hole of the vehicle body, seal the bottom of the metal frame of the lead wire hole with butyl sealing tape, and use a narrower butyl sealing tape at the gap between the cable and the bottom of the lead wire hole metal frame Winding is performed, thereby forming a sealing portion. When the cable in the lead wire hole is shaken by external influences, the butyl sealing tape can be well adhered to the surface of the cable, and it is not easy to fall off the cable to form a complete sealing system.

[0044] 2. Insert the embedded pipe, penetrate the butyl sealing tape, and expose a little, so that the position of the embedded pipe is easy to find. Pre-embedded pipes fall off during vibration.

[0045] 3. The MF850 airport runway self-leveling sealant (purchased from Zhengzhou...

Embodiment 3

[0048] Other processing steps are the same as those in Example 1, except that no pre-embedded pipe is provided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com