Efficient stirring turbine of vertical stirrer

A vertical mixer, high-efficiency technology, applied in the turbine field, can solve the problems of increased power consumption of the mixer, poor mixing effect, uneven mixing, etc., to achieve the effect of eliminating sludge precipitation, increasing drainage, and enhancing mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

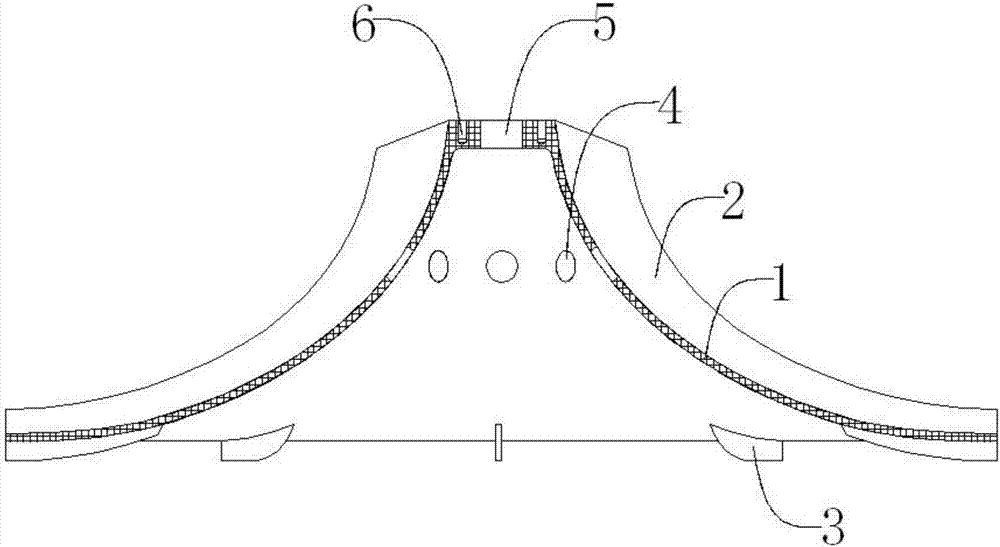

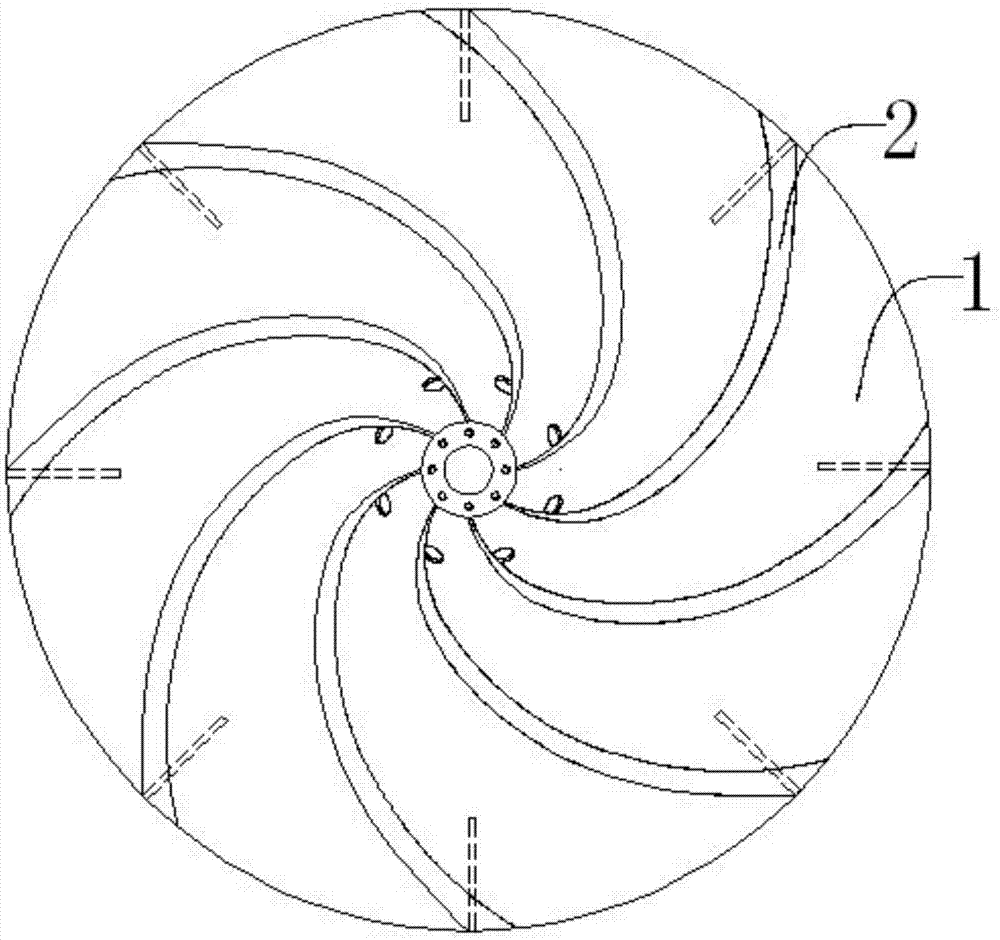

[0017] like figure 1 , figure 2 As shown, a high-efficiency stirring turbine of a vertical mixer includes an upper, small, lower, and large trumpet-shaped turbine body 1 formed by rotating a set curve around an arbitrary central axis, and no less than 3 pieces of turbines that are evenly arranged along the turbine body 1 The main blade 2, the number of auxiliary blades 3 uniformly arranged along the turbine body 1 is not less than 3, the number of guide holes 4 uniformly arranged along the turbine body 1 is not less than 3, the positioning hole 5, the installation Threaded hole 6, the main blade 2 is located outside the turbine body 1, the main blade 2 is integrally connected with the turbine body 1, and the main blade 2 extends from the bottom circumference of the turbine body 1 along the outer surface of the turbine body 1 to the At the top, the width of the main blade 2 gradually increases from bottom to top, the auxiliary blade 3 is located inside the turbine body 1, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com