Silicon carbide-hypereutectic silicon aluminum alloy composite material powder, preparation method and product

A composite material, silicon-aluminum alloy technology, applied in the field of powder metallurgy, can solve the problems of restricting the application of ordinary aluminum or aluminum alloy, easy to cause wear, etc., and achieve the effect of eliminating hard phase segregation, reducing contact probability, and lowering melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

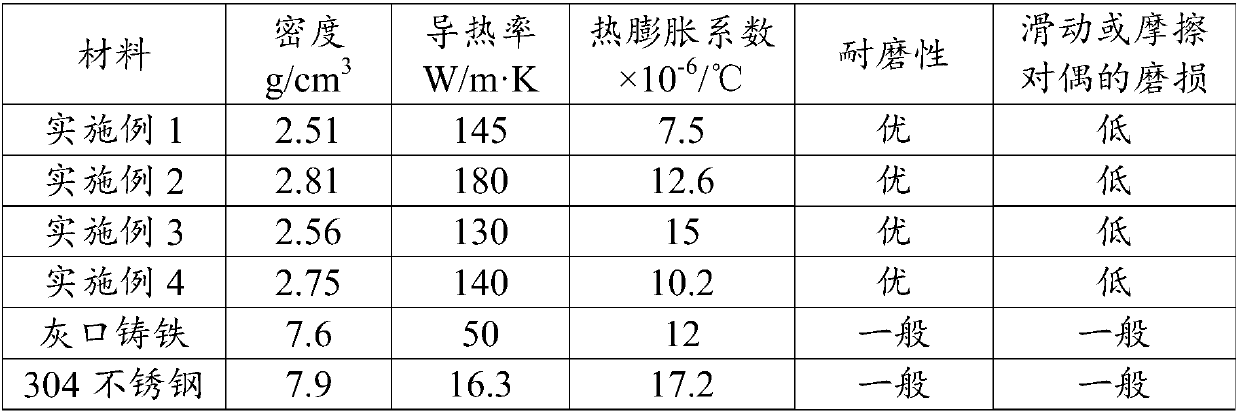

Embodiment 1

[0054] The invention provides a silicon carbide-hypereutectic silicon-aluminum alloy composite material powder. The raw materials include the following components according to weight percentage: 5% silicon carbide;

[0055] And alloy composition: 60% silicon, 0.5% iron and 34.5% aluminum.

[0056] The silicon carbide in the composite material powder has a particle size of 1-20 μm;

[0057] The grain size of primary silicon grains precipitated in the composite material powder is 1-10 μm.

[0058] The thermal expansion coefficient of the silicon carbide-hypereutectic silicon aluminum alloy composite powder is 7.5×10 -6 / °C.

[0059] The particle size of the silicon carbide-hypereutectic silicon aluminum alloy composite material powder is 10-200 μm.

[0060] The preparation method of described silicon carbide-hypereutectic silicon aluminum alloy composite material powder, comprises the following steps:

[0061] (1) Melting the alloy components to obtain an alloy melting beam,...

Embodiment 2

[0068] The invention provides a silicon carbide-hypereutectic silicon-aluminum alloy composite material powder. The raw materials include the following components according to weight percentage: 50% silicon carbide;

[0069] And alloy composition: 20% silicon, 1.0% copper, 2.0% magnesium and 27% aluminum.

[0070] The silicon carbide in the composite material powder has a particle size of 1-20 μm;

[0071] The grain size of primary silicon grains precipitated in the composite material powder is 1-10 μm.

[0072] The thermal expansion coefficient of the silicon carbide-hypereutectic silicon aluminum alloy composite powder is 12.6×10 -6 / °C.

[0073] The particle size of the silicon carbide-hypereutectic silicon aluminum alloy composite material powder is 10-200 μm.

[0074] The preparation method of described silicon carbide-hypereutectic silicon aluminum alloy composite material powder, comprises the following steps:

[0075] (1) Melting the alloy components to obtain an a...

Embodiment 3

[0083] The invention provides a silicon carbide-hypereutectic silicon-aluminum alloy composite material powder. The raw materials include the following components according to weight percentage: 5% silicon carbide;

[0084] And alloy composition: 20% silicon, 12% copper, 3.0% magnesium, 10% iron and 50% aluminum.

[0085] The silicon carbide in the composite material powder has a particle size of 1-20 μm;

[0086] The grain size of primary silicon grains precipitated in the composite material powder is 1-10 μm.

[0087] The thermal expansion coefficient of the silicon carbide-hypereutectic silicon aluminum alloy composite powder is 15×10 -6 / °C.

[0088] The particle size of the silicon carbide-hypereutectic silicon aluminum alloy composite material powder is 10-200 μm.

[0089] The preparation method of described silicon carbide-hypereutectic silicon aluminum alloy composite material powder, comprises the following steps:

[0090] (1) Melting the alloy components to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com