High-speed train ballastless track bed concrete construction surface line-to-line transport device and method

A kind of transportation device and concrete technology, which is applied in the field of rail transportation device between surface lines of ballastless ballast bed concrete construction of high-speed railway, can solve the problems of narrow construction site of ballastless ballast bed pouring work surface, interference of concrete transportation and other processes, and achieve logistics solution Organizational issues, fast shipping, and highly operable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

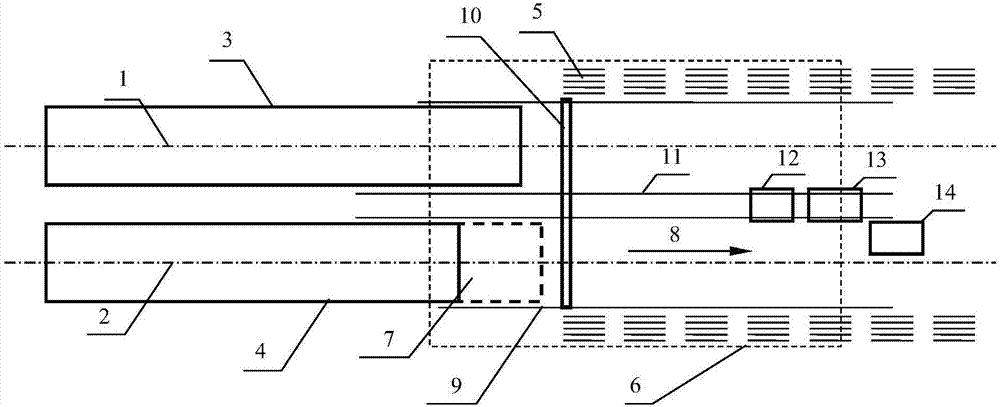

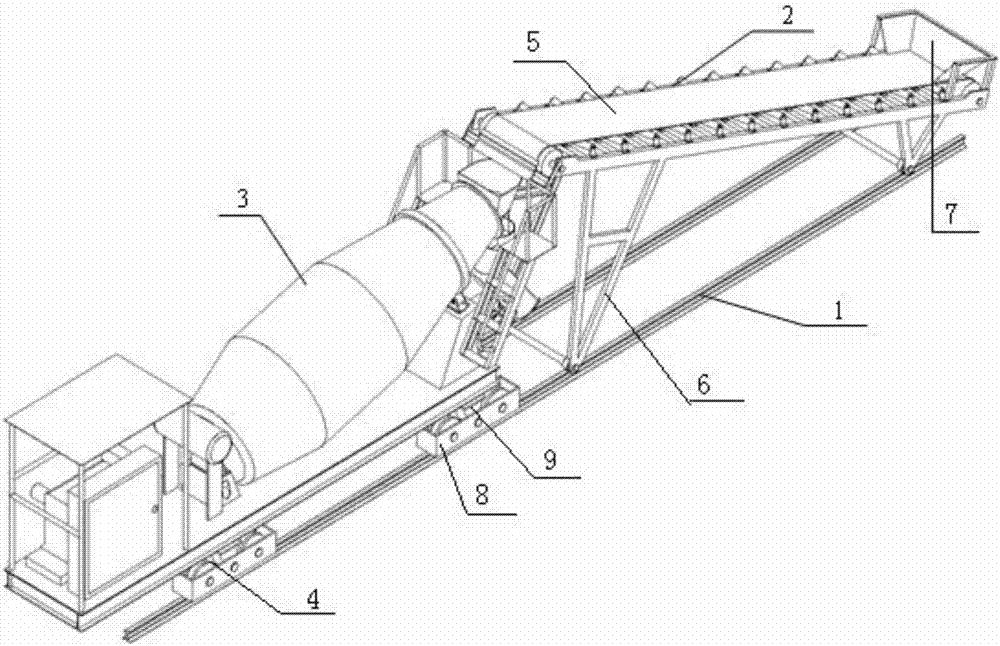

[0030] Embodiment 1: as figure 1 - image 3 As shown, a high-speed rail ballastless ballast bed concrete construction surface line rail transportation device, including two walking tracks 1, concrete mixer truck 3 and concrete belt conveyor 2, two walking tracks 1 are symmetrically installed on the left and right ballastless track beds Between them, the concrete mixer truck 3 is placed on the walking track 1 through the roller one 4, and one end is connected with the concrete belt conveyor 2, and the concrete belt conveyor 2 is placed on the walking track 1 through the roller two 4, and its concrete delivery outlet is facing the concrete mixer truck 3 feeding port.

[0031] Preferably, the concrete belt conveyor 2 includes a belt conveyor 5 and an inclined bracket 6, the belt conveyor 5 is installed obliquely on the inclined slope of the inclined bracket 6, the inclined slope is along the direction of the walking track 1, and the high end is the concrete delivery outlet.

[...

Embodiment 2

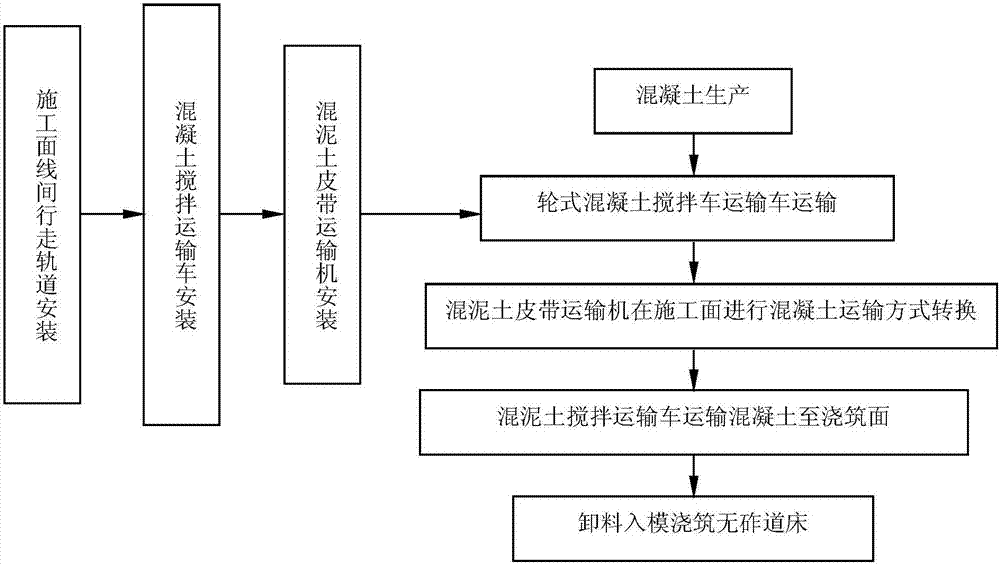

[0034] Embodiment 2: The above-mentioned method of using the rail transport device between the construction surface of the ballastless ballast bed concrete of the high-speed railway, the concrete belt conveyor for the construction surface of the ballastless ballast bed concrete is reversed from the wheeled concrete mixer truck to the concrete of the line rail type On the mixer truck, the trackless transportation mode outside the concrete construction surface is converted into the rail transportation mode between the inner lines of the construction surface, and the transportation between the ballastless ballast bed concrete construction surface lines is transported to the concrete pouring work surface by a rail-type concrete mixer truck, and poured The surface is directly discharged into the mold, and the specific method includes the following steps:

[0035] 1) Install and fix the running track between the lines: install two running tracks in the middle of the double-line balla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com