Airbag-assisted pipeline sliding and floating down the ditch method

A technology for auxiliary pipelines and pipelines, applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as undiscovered pipeline trench construction methods, solve on-site coordination and command problems, and reduce construction costs , high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] An embodiment is illustrated in conjunction with the accompanying drawings:

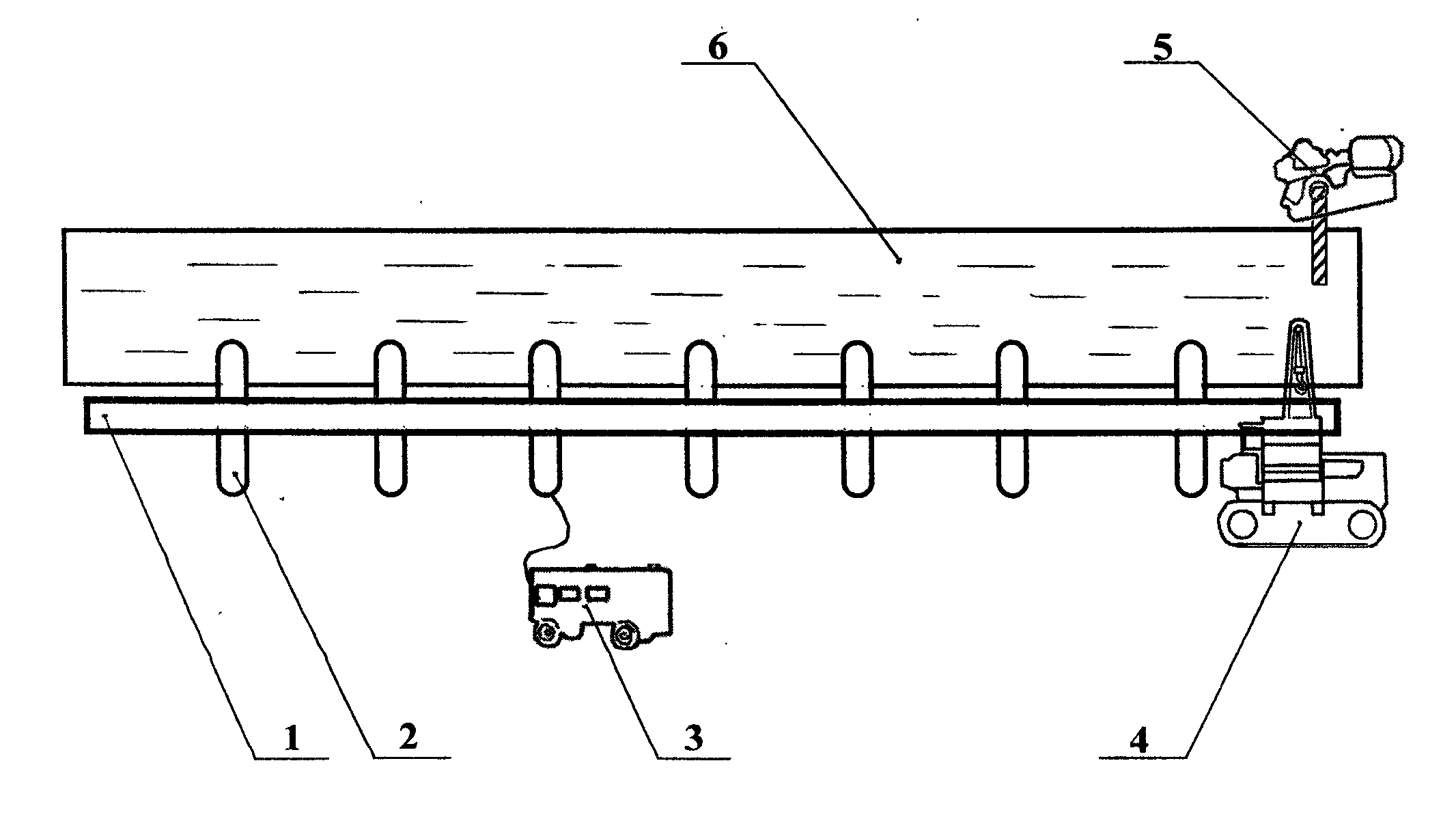

[0017] attached figure 2 Among them, 1 is a pipeline, 2 is an air bag, 3 is an air compressor, 4 is a pipelayer, 5 is a water pump, and 6 is a trench filled with water.

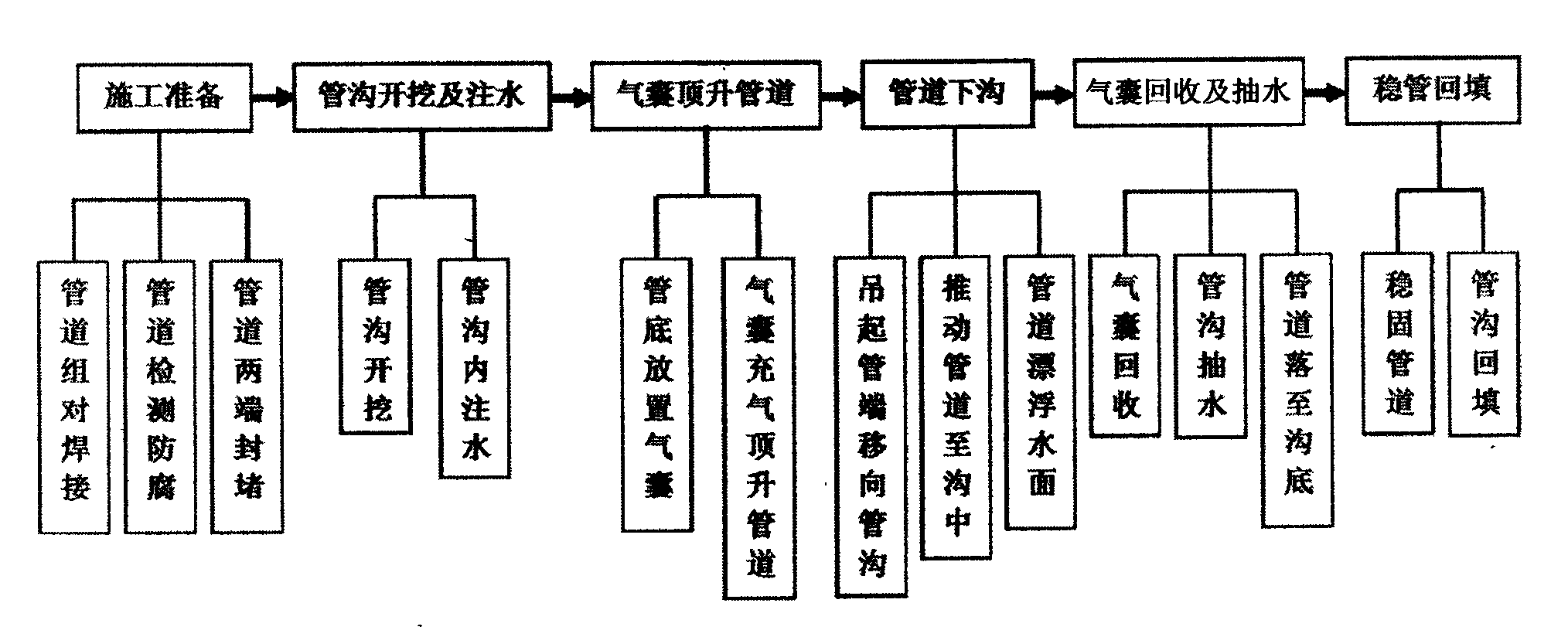

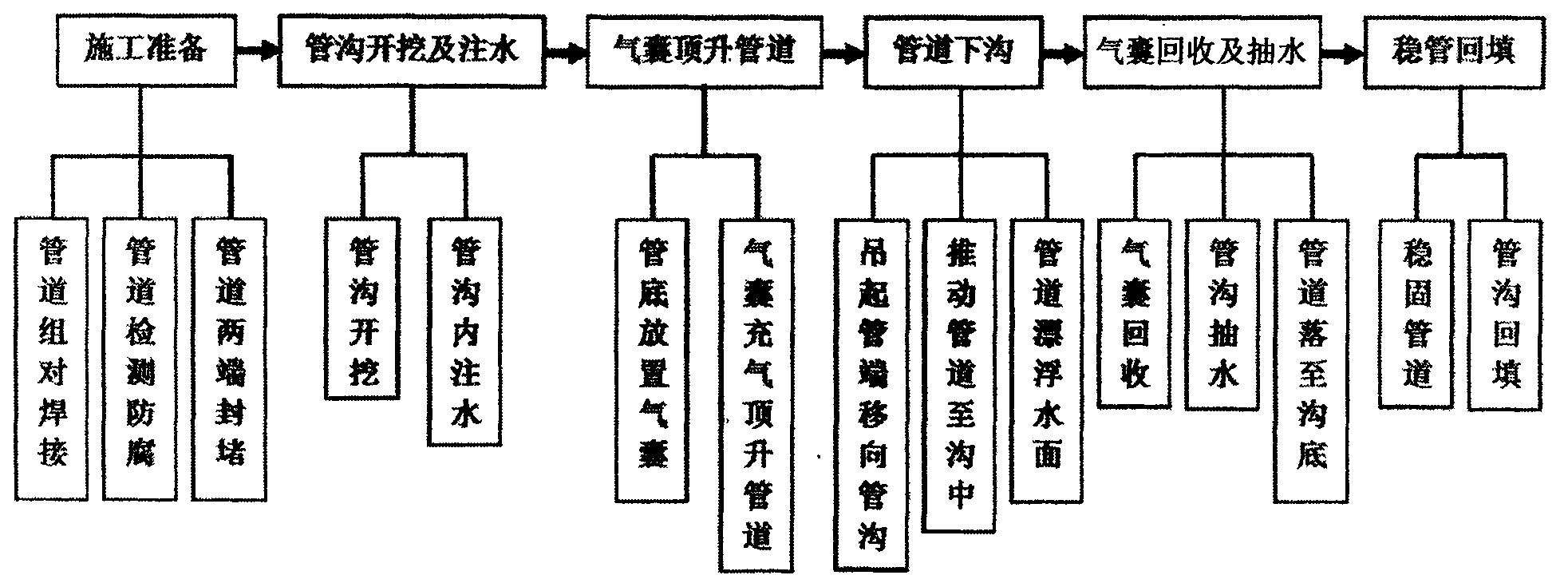

[0018] Depend on figure 1 As shown, the basic construction procedure and the brief technical content of each process of the ditching method are:

[0019] Construction preparation: pipeline assembly, welding, welding joint detection and anti-corrosion treatment, welding blind plate sealing at both ends of pipeline 1.

[0020] Trench excavation and water injection: Excavate the pipe trench 6 on one side of the pipeline 1, and fill the pipe trench 6 with water from the river. The groundwater level in the water network area is relatively high, and half ditch water can seep out in the pipe ditch 6 sometimes.

[0021] Air bag jacking pipeline: Place a plurality of air bags 2 with a diameter of 1 meter and a length of 6 meters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com