Waterproof and breathable single-yarn drill composite fabric

A technology of waterproof, breathable and composite fabrics, which is applied in the field of composite fabrics, can solve the problems of single fabric functions, etc., and achieve the effect of comfortable wearing and excellent waterproof and breathable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments listed in the present invention are only used to help understand the present invention, and should not be interpreted as limiting the protection scope of the present invention. For those of ordinary skill in the art, they can also Improvements and modifications are made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

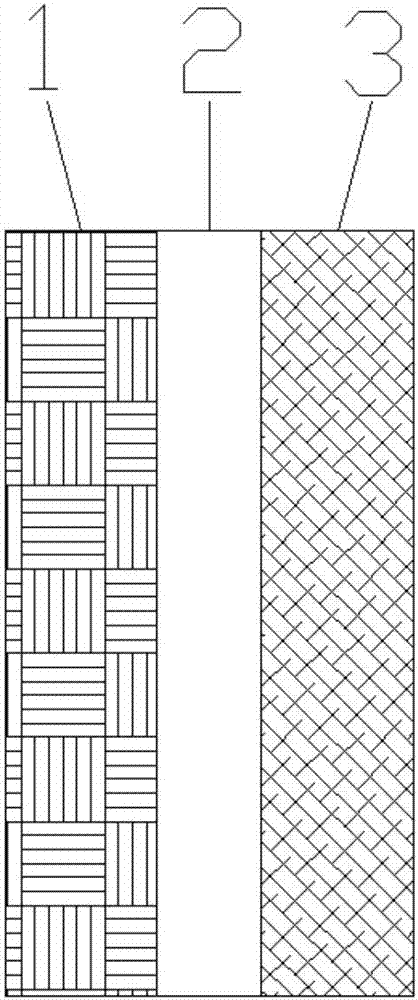

[0020] Such as figure 1 As shown, a waterproof and breathable gauze composite fabric introduced in the present invention includes: Telico fabric 1, waterproof and moisture-permeable membrane 2, and gauze fabric 3 arranged in sequence from outside to inside are fixed and bonded with glue. The composite glue can be one or more of epoxy resin adhesives, phenolic resin adhesives, acetal resin adhesives, shellac resin adhesives, epoxy-phenolic resin adhesives, and phenolic-acetal resin adhesives. The gauze fabric 3 can be one of full gauze, elastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com