Pipe inner circumferential weld pressure test tool and pressure test method

A technology of girth weld and pressure test, which is applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, measuring devices, etc. The effect of work efficiency, water injection reduction, and enhanced safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. And the features in the embodiments can be combined with each other.

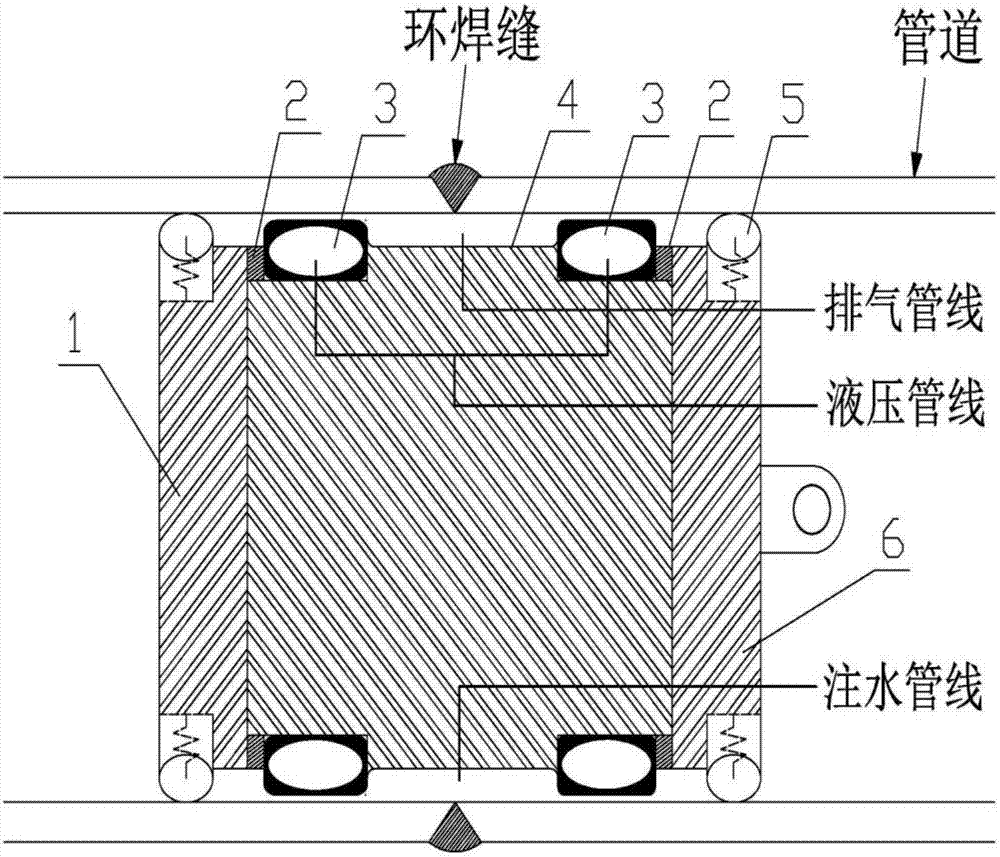

[0030] Such as figure 1 As shown, the embodiment of the present invention provides a pressure test tool for inner girth welds in pipes, including a cylindrical pressure test body 4, and the outer peripheries of both ends of the pressure test body 4 are respectively provided with several pulley blocks 5 at intervals along the circumferential direction. The outer circumference of the pressure test body 4 is provided with two rubber sealing rings 3 at intervals along the axial direction. The distance between the two rubber sealing rings is slightly larger than the width of the girth weld and its heat-affected zone. The positioning error of the pressing tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com