Pipe water-pressure detecting equipment

A technology for hydraulic testing and pipes, applied to measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems of large axial water sealing area, complex body structure, and high cost of use, and achieve water injection Less quantity, simple equipment structure and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

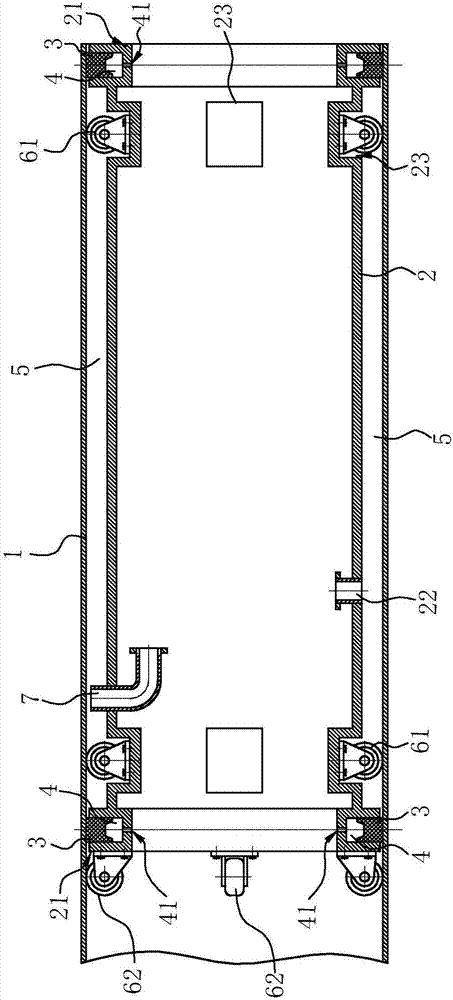

[0019] Such as figure 1 As shown, the pipe water pressure detection equipment of the embodiment of the present invention includes a cylinder 2 and a tensioning mechanism, wherein the cylinder 2 can be built into the pipe 1 to be tested, the inside of the cylinder 2 is hollow, and the two ends of the cylinder 2 are arranged There is an annular groove 21 with an opening facing outward, and a seal 3 is arranged in the annular groove 21; there are many ways to connect the cylinder body 2 and the annular groove 21, and the cylinder body 2 and the annular groove 21 can be integrally formed. The cylinder body 2 and the annular groove 21 can also be connected together by means of welding. In this embodiment, preferably, both ends of the cylinder body 2 are fixedly connected to an outer wall of the annular groove 21 by welding. structure.

[0020] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com