Device for injection of high chlorine gasoline and diesel oil into coking heating furnace for high temperature reaction for dechlorination

A high-temperature reaction, gasoline and diesel technology, applied in the field of oil refining equipment, can solve the problems of limited resources not being fully utilized, no elimination methods, equipment corrosion, etc., to reduce the amount of water injection in the heating furnace, ensure long-term operation, and increase safety The effect of the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

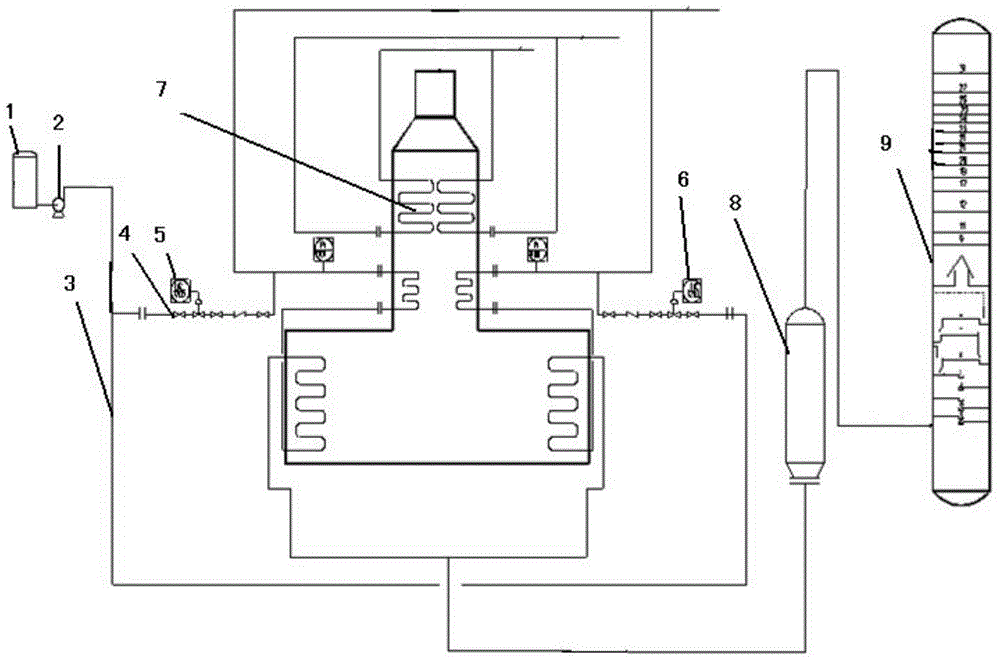

[0010] According to the accompanying drawings of the description, the high-chlorination gasoline and diesel oil of the present invention is injected into the high-temperature reaction dechlorination device of the coking heating furnace and is further explained as follows: figure 1 As shown, the high-chlorine gasoline and diesel are stored in the high-chloride oil tank 1, and the high-chloride gasoline and diesel are extracted from the tank through the low-temperature high-pressure oil pump 2, and then go through the oil pipeline 3 to the heating furnace 7, and the oil pipeline 3 is provided with a pressure sensor 5 and a flow sensor. 6. Regulating valve 4 and other instrumentation equipment control the pressure of the delivery pipeline and the flow rate of high-chlorine gasoline and diesel oil entering the heating furnace tube through the regulating valve 4. Inject high-chlorine gasoline and diesel instead of demineralized water into the heating furnace 7 and heat it to about 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com