Multi-camera vision detection system and detection method

A multi-camera vision and detection system technology, applied in the direction of optical testing defects/defects, can solve the problems of slow acquisition speed and high cost, and achieve the effect of reducing the process, reducing the detection cost and improving the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

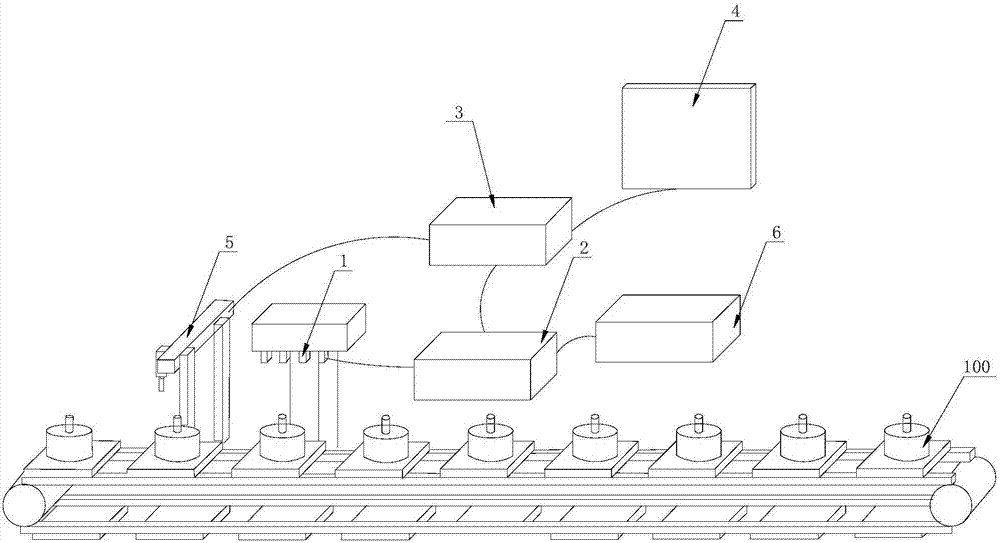

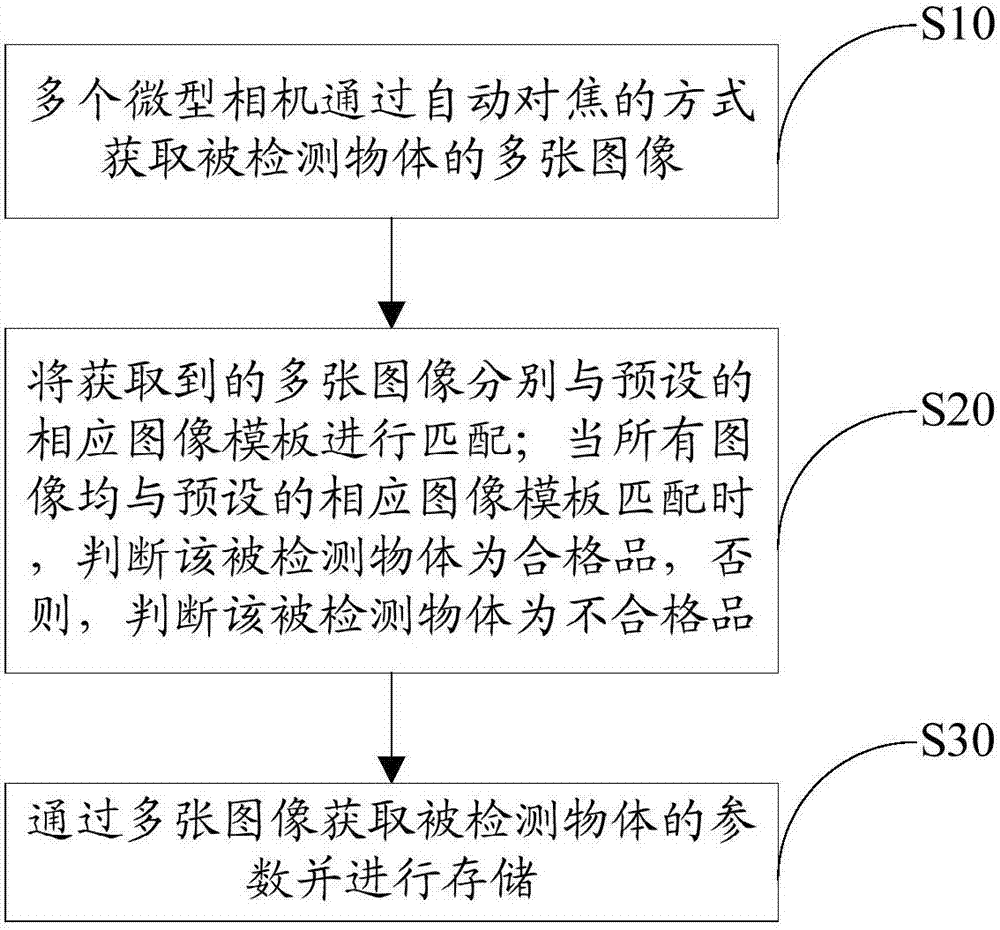

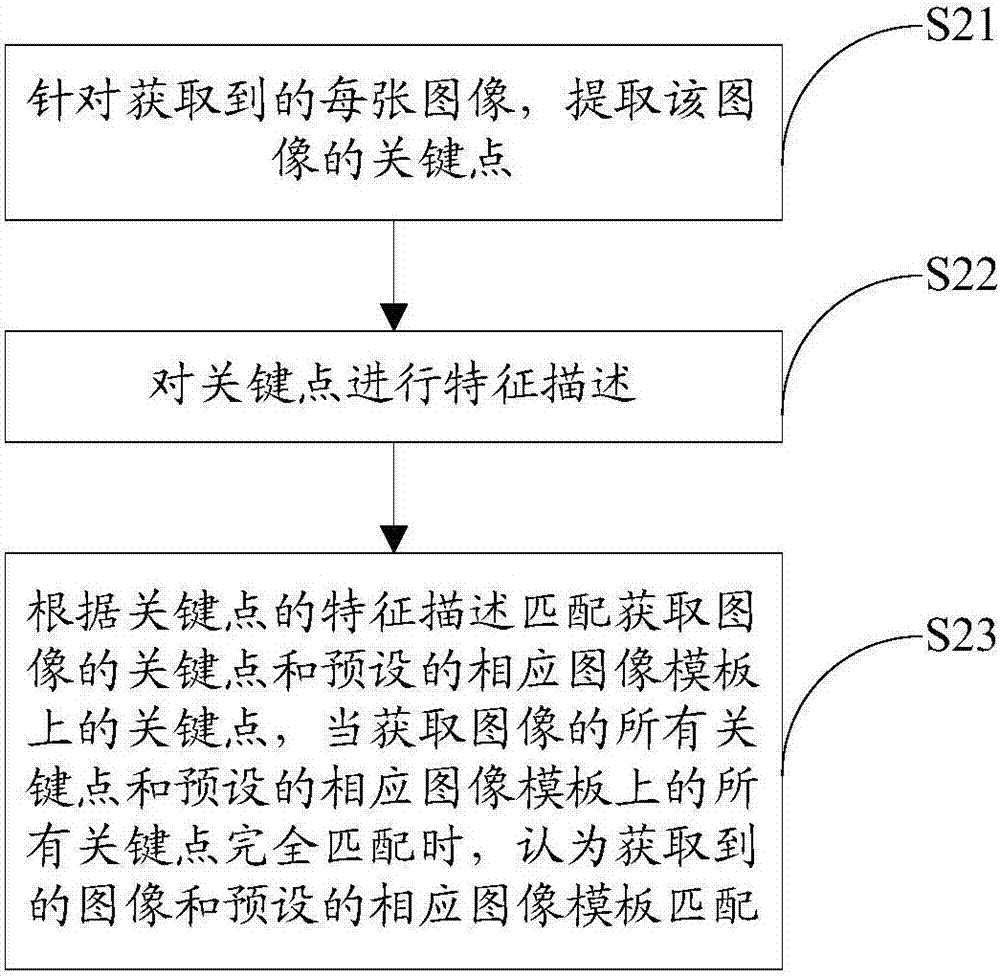

[0028] Such as figure 1 As shown, the multi-camera visual inspection system provided in this embodiment includes a plurality of miniature cameras 1 and an image processing unit 2 . Multiple micro-cameras 1 are arranged around the detected object 100 , and the multiple micro-cameras 1 acquire multiple images of the detected object 100 by auto-focusing. The image processing unit 2 is electrically connected to a plurality of miniature cameras 1, and matches the acquired images with the preset corresponding image templates; when all the images match the preset corresponding image templates, it is judged that the detected object It is a qualified product, otherwise, it is judged that the detected object is a non-conforming product.

[0029] The multi-camera visual inspection system provided in this embodiment is provided with a plurality of miniature cameras 1, and each miniature camera has an auto-focus function. When the detected object has multiple planes with different height...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com