Microscopic scanning automatic focusing compensation system and compensation method

An automatic focus and compensation system technology, applied in microscopes, optics, instruments, etc., can solve problems such as low efficiency and time wasting, and achieve the effect of reducing deviation and moving efficiently and quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

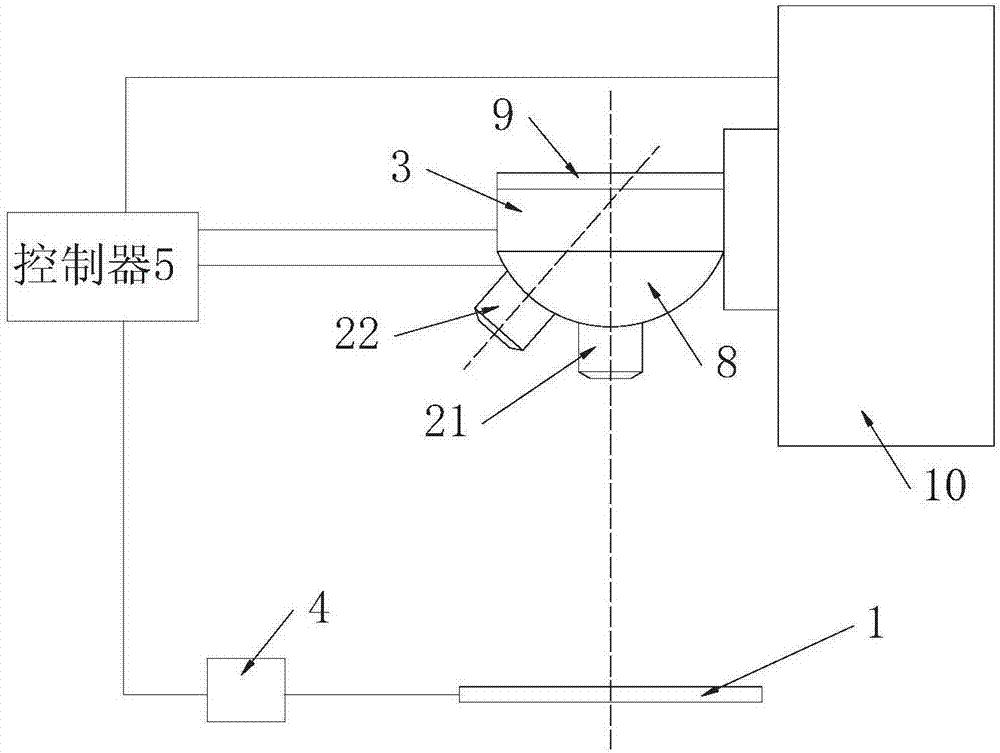

[0025] see figure 1 The microscopic scanning autofocus compensation system shown includes a stage 1 that can be along the x-axis direction and the y-axis direction in the horizontal plane, and objective lenses 21 and 22 for imaging objects on the stage are arranged above the stage , a fast focus module 3 and a position detection device 4 for real-time detection of the position of the stage on the x-axis and y-axis, a controller 5, an electric nose wheel 8, a bracket 9, and a bracket lifting electric drive device 10.

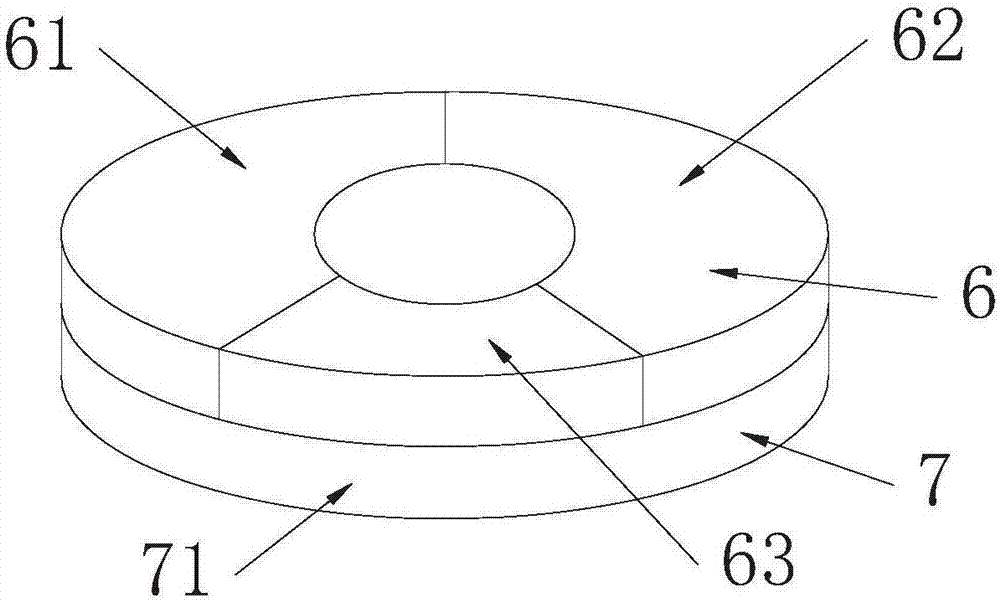

[0026] The fast focusing module 3 includes an optical axis tilt compensation module 6 and a focus z-axis deviation compensation module 7 .

[0027] The optical axis inclination compensation module 6 is three sector-shaped piezoelectric ceramics 61, 62, 63 that have an inverse piezoelectric effect and can be extended or shortened in the z-axis direction, and are used to respectively supply power to the three sector-shaped piezoelectric ceramics to Three tilt comp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap