Static release gear for production of flexible composite insulating material

An electrostatic discharge device and composite insulation technology, which is applied to static electricity, electrical components and other directions, can solve the problems of loose composite insulation materials, difficulty in picking and placing, handling, and transportation, and affect the quality of soft composite insulation material coil products. Short release path, easy to use, good electrostatic discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further specifically described below through embodiments and in conjunction with the accompanying drawings.

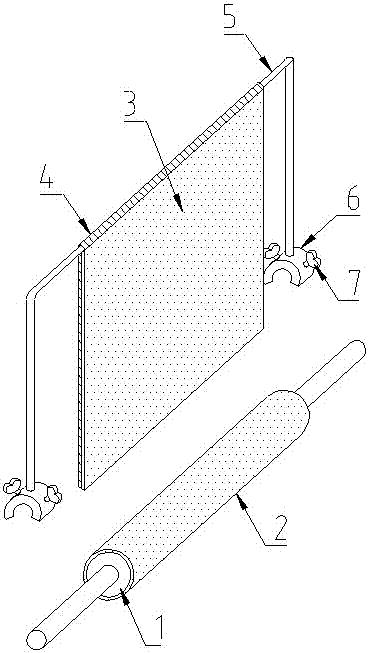

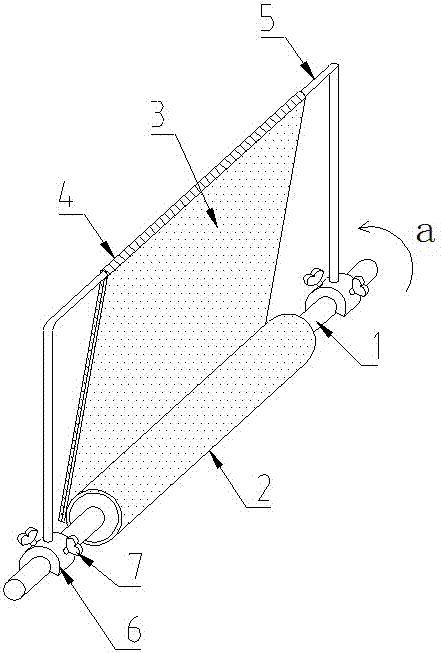

[0017] like figure 1 As shown, an electrostatic discharge device for producing soft composite insulating materials provided by the present invention includes a guide roller 1. Generally, a winding core is set on the guide roller 1, and then the soft composite insulating material is wound on the winding core, which is convenient Transport and storage. Guide roller 1 is an aluminum alloy guide roller. The aluminum alloy guide roller has good electrical conductivity, is convenient for electrostatic discharge, and has a stable structure, high strength, and high cost performance. The outer surface of the guide roller 1 is provided with an antistatic rubber layer 2 for collecting static electricity from the inside of the soft composite insulating material coil. Also included is an antistatic rubber sheet 3 for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com