Zinc-based alloy material, preparation method of zinc-based alloy material, high-resistance thin film and preparation method of high-resistance thin film

An alloy material, high resistance technology, applied in non-adjustable metal resistors, metal material coating processes, resistors, etc., can solve problems such as affecting touch sensitivity and affecting touch effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

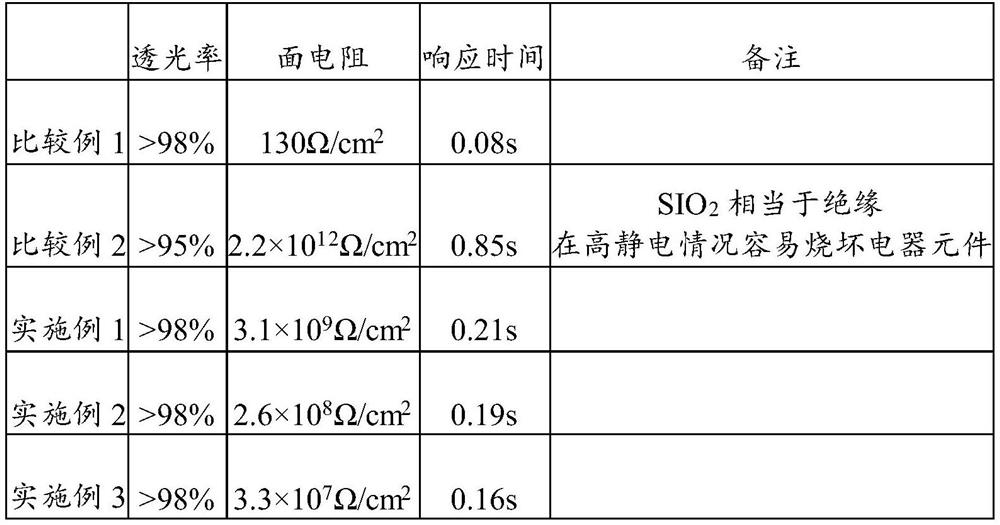

Examples

preparation example Construction

[0028] The invention provides a preparation method of a zinc-based alloy material, comprising the following steps:

[0029] A) Under the oxygen atmosphere, heat treatment and deoxidize the zinc-based alloy in a rough billet container to obtain alloy material powder;

[0030] The zinc-based alloy includes 60-99wt% zinc and 1-40wt% aluminum;

[0031] The temperature of the heat treatment is 1100~1350℃; the time of the heat treatment is 60~120min;

[0032] B) The alloy material powder is sequentially subjected to cold isostatic pressing and hot isostatic pressing to obtain a zinc-based alloy material.

[0033] In the present invention, the composition of the zinc-based alloy is 60-99% zinc and 1-40% aluminum, and the mass content of zinc in the zinc-based alloy is preferably 60-99%, more preferably 65-95% %, most preferably 70-90%, specifically, in the embodiment of the present invention, it can be 70%, 76% or 94%; the mass content of aluminum in the zinc-based alloy is prefera...

example 1

[0074] 70 g of silicon and 30 g of aluminum were mixed, and the mixture was centrifugally stirred for 70 min at a speed of 2300 rpm to obtain a mixed powder.

[0075] The mixed powder was poured into a rough container, and treated at 1200° C. for 90 min under an oxygen atmosphere to obtain high-temperature deoxidized powder.

[0076] The high-temperature deoxidized powder was subjected to cold isostatic pressing, the pressure was 200MPa, and the pressure holding time was 15min, and the obtained rough billet had a density of 35%.

[0077] Put the preformed material blank into a container of corresponding size, encapsulate the container with the rough blank, and vacuumize the container to 0.4pa. The above-mentioned container was placed in a hot isostatic pressing furnace, and hot isostatic pressing was carried out at 1150° C., the holding time was 2.5 hours, and the pressure of argon was 160 MPa to obtain ZnO:Al, ZnO or ZnN:AlN composition target.

[0078] The substrate is clea...

example 2

[0082] 76g of silicon and 24g of aluminum were mixed, and the mixture was centrifugally stirred for 80min at a speed of 2400 rpm to obtain a mixed powder.

[0083] The mixed powder was poured into a rough container, and treated at 1250° C. for 110 min under an oxygen atmosphere to obtain high-temperature deoxidized powder.

[0084] The high-temperature deoxidized powder was subjected to cold isostatic pressing, the pressure was 230MPa, and the pressure holding time was 18min, and the obtained rough billet had a density of 42%.

[0085] Put the preformed material blank into a container of corresponding size, encapsulate the container with the rough blank, and vacuumize it to 0.3pa. The above container was placed in a hot isostatic pressing furnace, and hot isostatic pressing was carried out at 1200° C., the holding time was 4 hours, and the pressure of argon was 180 MPa to obtain a target of ZnO:Al, ZnO or ZnN:AlN composition.

[0086] The substrate is cleaned by water sprayin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com