Powdery coating with electrostatic repellent effects and preparation method thereof

A powder coating, electrostatic technology, applied in powder coatings, conductive coatings, polyester coatings, etc., can solve the problems of inability to color, large pollution, high relative density, etc., to achieve good electrostatic discharge effect, uniform texture appearance, resistance low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

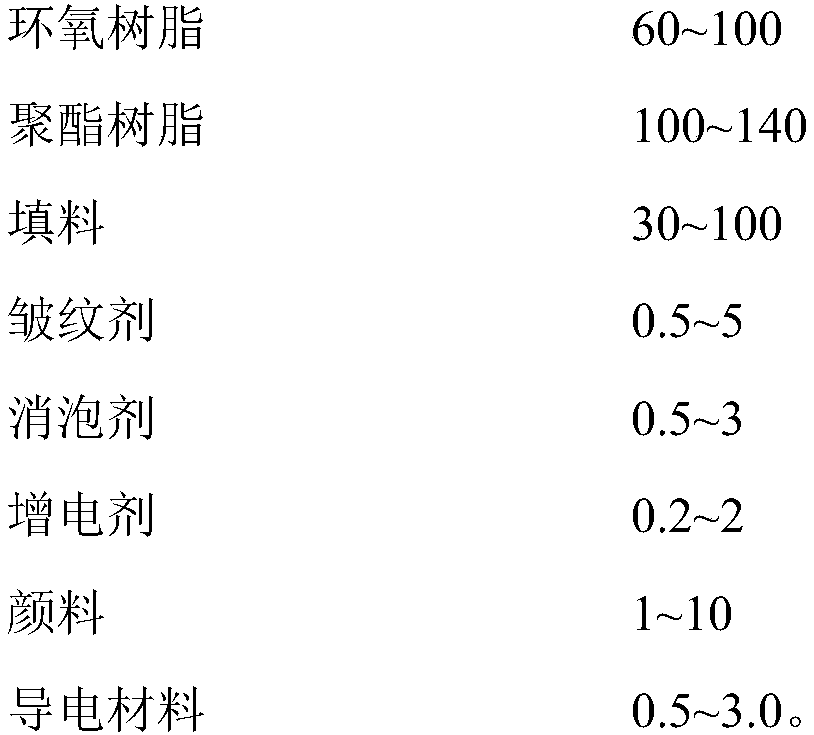

[0030] The powder coating with anti-static effect provided in this embodiment includes the following components by mass ratio:

[0031]

[0032] Wherein the epoxy resin is a bisphenol A epoxy resin, and the epoxy equivalent of the bisphenol A epoxy resin is 600-900 g / eq.

[0033] The polyester resin is a saturated carboxyl-terminated polyester resin with an acid value of 45-75 mgKOH / g and a softening point of 85-95°C.

[0034] The fillers are titanium dioxide and barium sulfate, 30 parts and 50 parts respectively.

[0035] Wrinkle agents are acrylates.

[0036] The defoaming agent is benzoin (benzoin) with a melting point of 137°C.

[0037] The booster is a quaternary ammonium salt.

[0038] The pigment is an inorganic pigment, and the inorganic pigment is iron yellow.

[0039] The conductive material is a high-conductivity chopped carbon fiber material, and its resistivity is less than 0.0014Ω.cm.

[0040] The preparation method of the powder coating with the effect o...

Embodiment 2

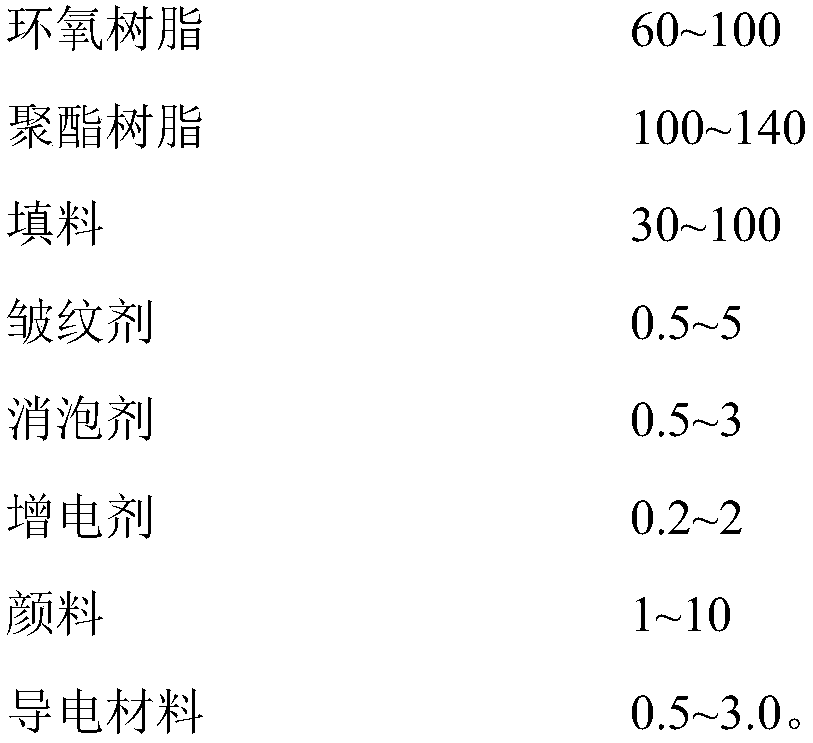

[0048] The powder coating with anti-static effect provided in this embodiment includes the following components by mass ratio:

[0049]

[0050] Wherein the epoxy resin is a bisphenol A epoxy resin, and the epoxy equivalent of the bisphenol A epoxy resin is 600-900 g / eq.

[0051] The polyester resin is a saturated carboxyl-terminated polyester resin with an acid value of 45-75 mgKOH / g and a softening point of 85-95°C.

[0052] The fillers are titanium dioxide and mica powder, 30 and 50 parts respectively.

[0053] The wrinkling agent is cellulose acetate.

[0054] The defoaming agent is benzoin (benzoin) with a melting point of 137°C.

[0055] The booster is a quaternary ammonium salt.

[0056] The pigment is carbon black.

[0057] The conductive material is chopped carbon fiber with high conductivity, and its resistivity is less than 0.0014Ω.cm.

[0058] The preparation method is the same as in Example 1.

Embodiment 3

[0060] The powder coating with anti-static effect provided in this embodiment includes the following components by mass ratio:

[0061]

[0062] The concrete kind of each component is with embodiment 1. Wherein the epoxy resin is a bisphenol A epoxy resin, and the epoxy equivalent of the bisphenol A epoxy resin is 600-900 g / eq.

[0063] The polyester resin is a saturated carboxyl-terminated polyester resin with an acid value of 45-75 mgKOH / g and a softening point of 85-95°C.

[0064] The filler is mica powder.

[0065] The wrinkle agent is polytetrafluoroethylene.

[0066] The defoaming agent is benzoin (benzoin) with a melting point of 137°C.

[0067] The booster is a quaternary ammonium salt.

[0068] Pigment iron red.

[0069] The conductive material is graphene

[0070] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com