Green compact and method for producing same

A manufacturing method and powder technology, which is applied in the field of powder compaction and its manufacturing, can solve problems such as inability to reduce costs, and achieve the effects of preventing damage, reducing costs, and avoiding manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] An embodiment of the present invention will be described below based on specific examples.

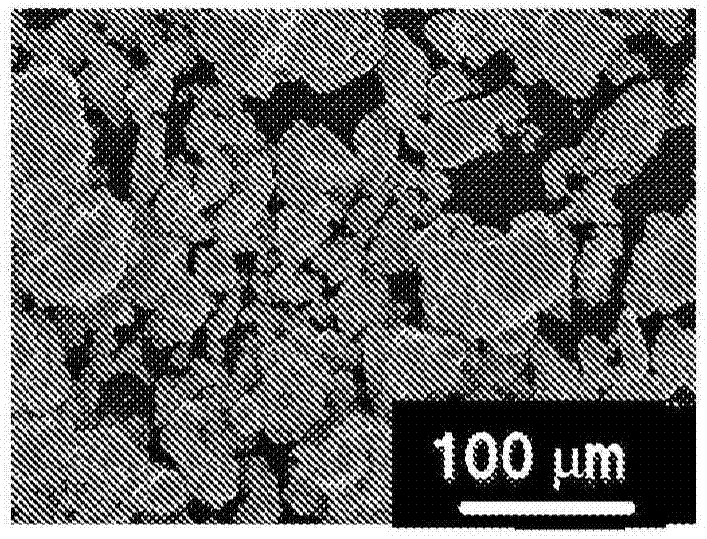

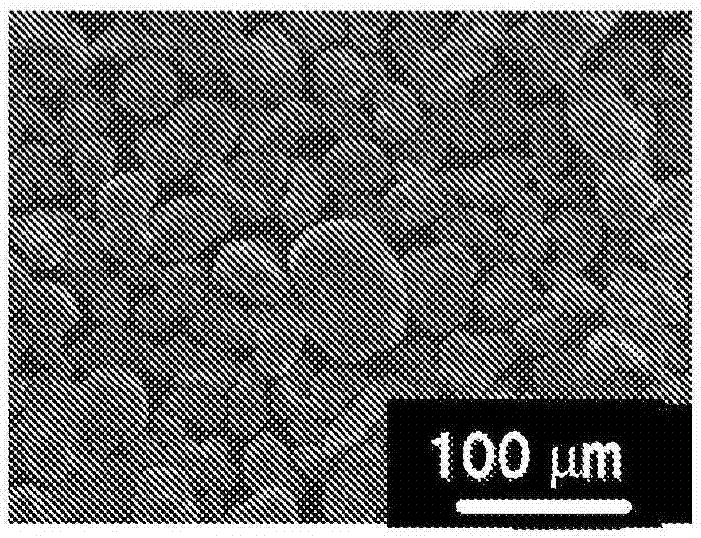

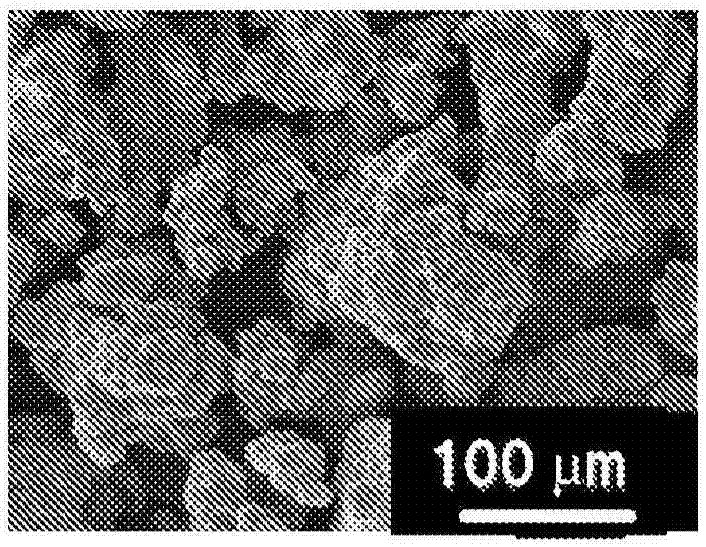

[0047] First, test pieces of Examples 1 and 2 and Comparative Examples 1 to 4 were prepared using six types of pure iron powders having mutually different shapes as the base metal powder serving as the main raw material of the raw material powder. Here, in Examples 1 and 2 and Comparative Example 1, the pure iron powder produced by the water atomization method was used, and in Comparative Examples 2 to 4, the pure iron powder produced by the reduction method was used. For all powders, only powders with a sieve size of 250 μm or less are used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com