Partially oxidized graphene and preparation method therefor

A technology of graphene and graphite, which is applied in the field of partial graphene oxide and its preparation, can solve the problems of small graphene, difficult to obtain, insufficient peeling yield, etc., and achieve improved sheet resistance, excellent dispersibility, and excellent dispersibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0076] step 1

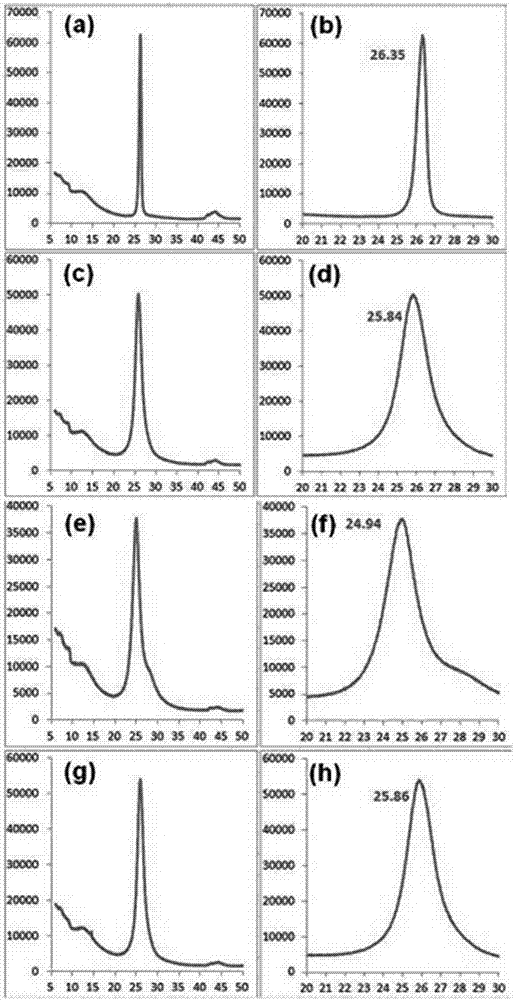

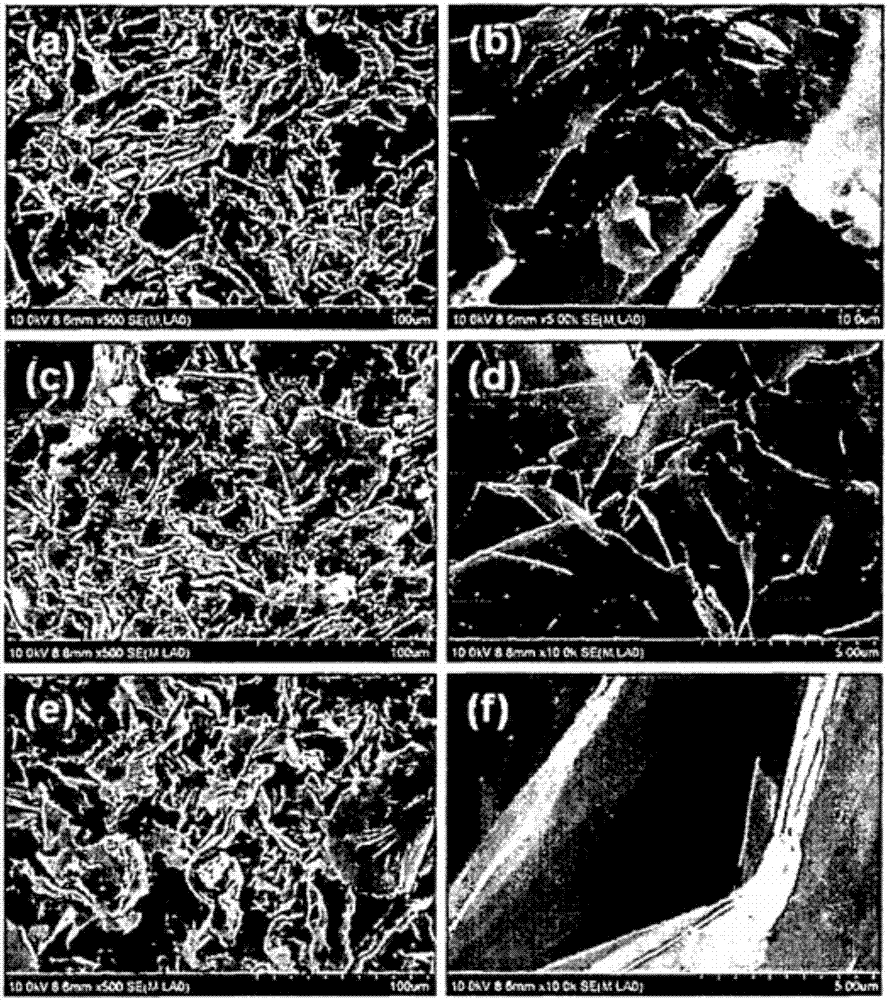

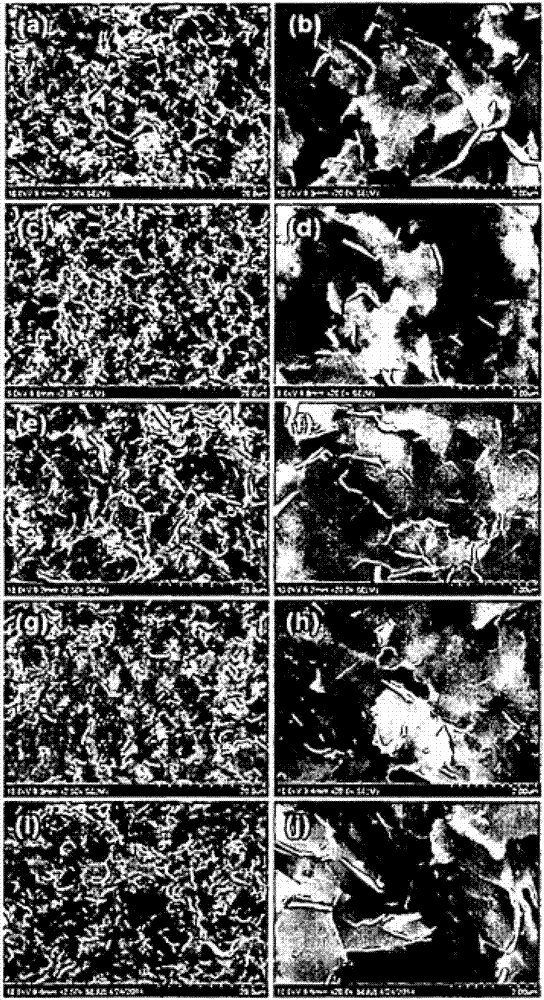

[0077]2.5 g of raw graphite (BNB90) was added to 262.5 mL of ice-cooled mixed solution of sulfuric acid and nitric acid (volume ratio of sulfuric acid to nitric acid=3:1), and stirred at about 500 rpm. They were reacted in an oil bath at the temperature and time shown in Table 1 below, thereby partially oxidizing the original graphite. After the reaction, the reaction mixture was cooled to room temperature, and slowly added to 1 L of ice-cooled distilled water. The reaction solution diluted with distilled water was filtered under vacuum to recover part of the graphite oxide, and dried overnight in an oven at 100°C. The partially oxidized graphite prepared according to the reaction temperature and reaction time was named "poGF-(reaction temperature)-(reaction time)", as shown in Table 1 below.

[0078] [Table 1]

[0079] Example temperature reflex Reaction time poGF-75-20 75℃ 20 hours poGF-85-20 85℃ 20 hours poGF-90-16 90℃ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com