Cutting and sewing process of suit collar

A process method and technology for suits, which are applied in the field of cutting and sewing technology of suit collars, can solve the problems of difficulty in grasping the material properties of collar fabrics, long process route of edging, and large area of collar fabrics, so as to increase the difficulty of cutting and the number of processes. , The effect of reducing the area of the collar and shortening the route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

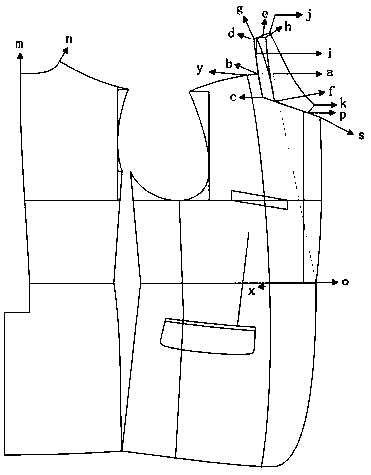

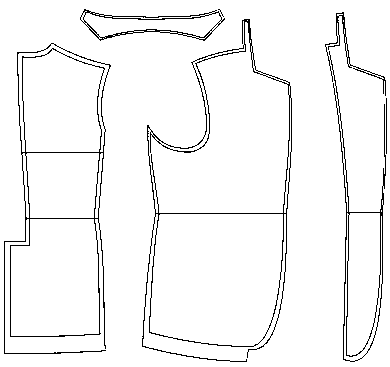

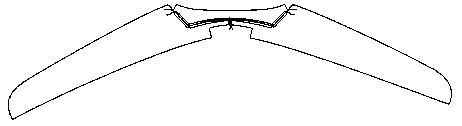

[0035] like figure 1 , image 3 , Figure 5 , Image 6 , Figure 8 Shown, the present invention provides a kind of suit collar cutting and the new technological method of sewing, concrete steps;

[0036] 1) Draw the collar structure graphics based on the neckline of the suit piece, which mainly includes the drawing of the bottom collar and lapel;

[0037] 2) According to the drawn collar structure diagram, draw the bottom collar piece ( / or vermicelli) and tailor it;

[0038] 3) Cut the lapel of the suit according to the collar structure diagram, including the tailoring of the collar and the collar;

[0039] 4) Make the collar process sequentially according to the sequential sewing process.

[0040] like figure 1 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com