Continuous melting furnace capable of highly precisely controlling partial wall of tubular product

A high-precision, continuous furnace technology, used in continuous furnaces and quartz furnaces, can solve problems such as affecting product quality and inconsistent tube wall thickness, and achieve the effect of simple structure, uniform tube wall thickness and uniform gap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] like Figure 1-3 shown.

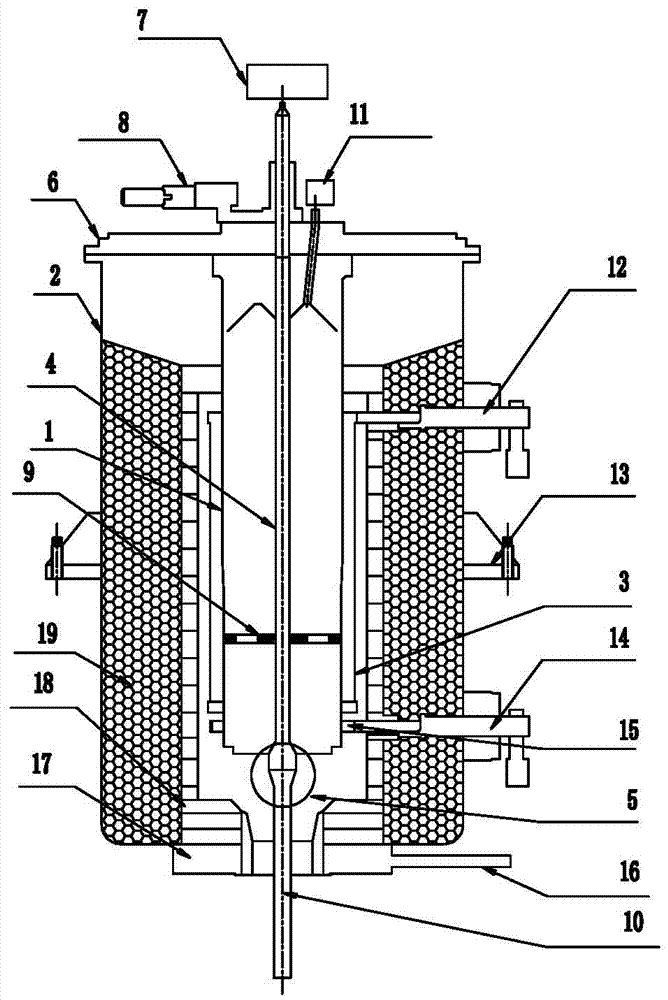

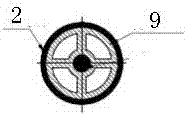

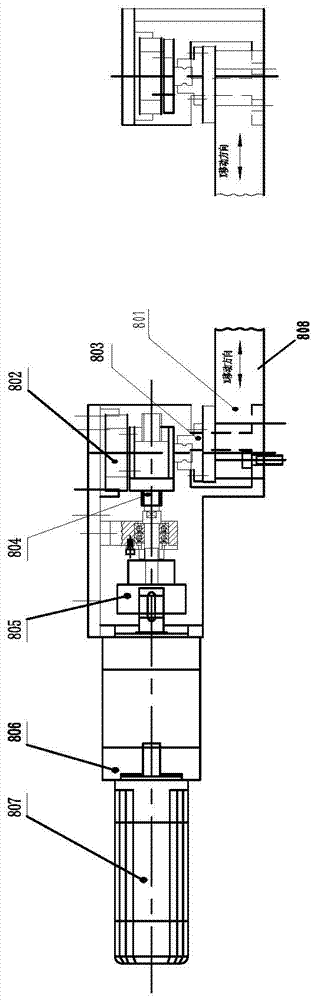

[0024] A continuous melting furnace capable of controlling the partial wall of pipes with high precision. It includes a crucible 1, a furnace body 2, a heater 3, a core rod 4 and a forming mold 5. The length of the core rod 4 is generally between 2 and 2.8 meters, such as figure 1 As shown, the crucible 1 is installed in the furnace body 2, and the heater 3 is powered by the main electrode and wrapped around the outer ring of the crucible 1, so that the temperature of the crucible 1 is distributed in steps from top to bottom (preheating zone-melting zone-exhaust zone—the temperature in the forming zone is different), the lower end of the core rod 4 extends into the crucible 1 through the furnace cover 6 and is opposite to the forming mold 5 installed at the lower end of the crucible 1, the core rod 4 is a hollow structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com