A kind of preparation method of ceramic wire drawing die

A wire drawing die and ceramic technology, applied in the direction of wire drawing die, etc., can solve the problems of high cost of ceramic wire drawing die, high polycrystalline production cost, die wear failure, etc., to avoid metal bonding phase, good dimensional stability, change wear and tear The effect of the mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

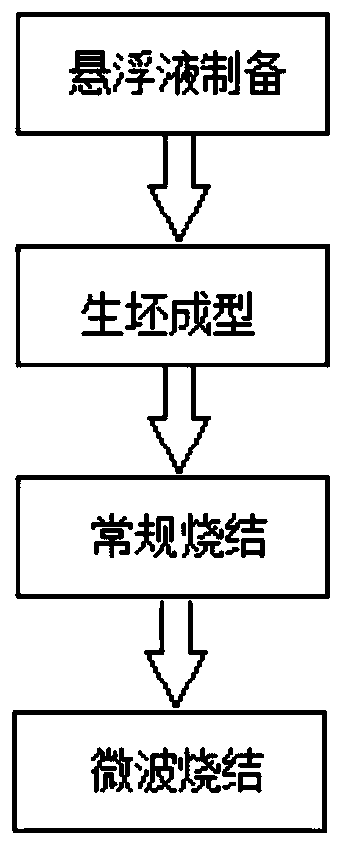

[0025] The technical process of the ceramic wire drawing die preparation method involved in this embodiment includes four steps of suspension preparation, green body forming, conventional sintering and microwave sintering:

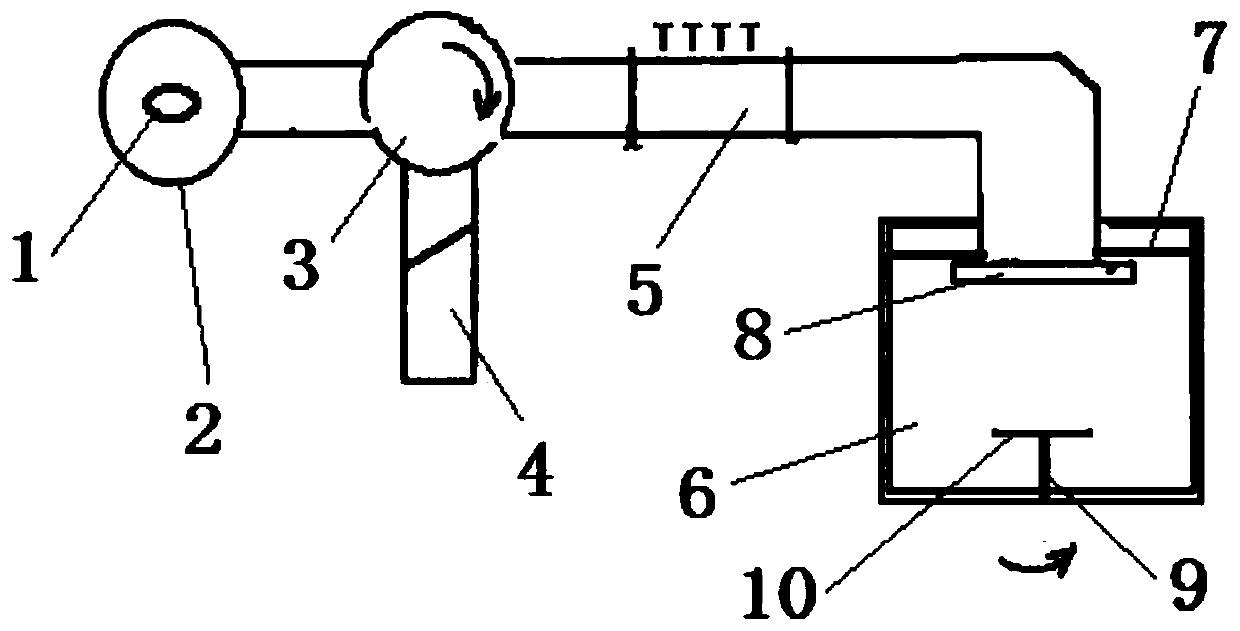

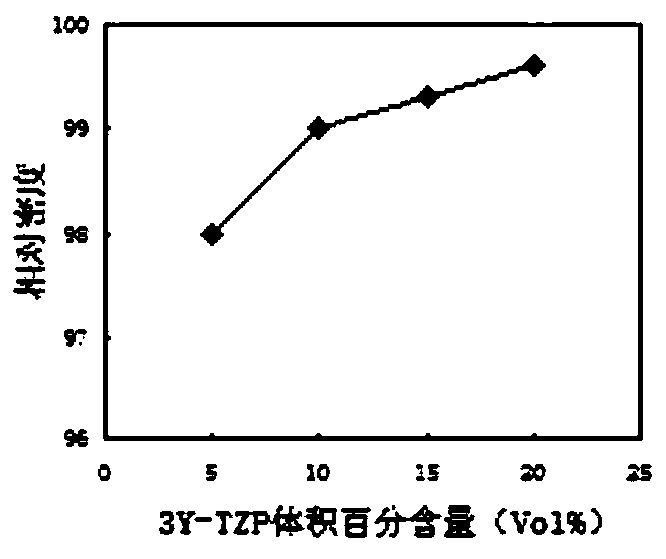

[0026] (1) Suspension preparation: Mix acrylamide monomer with N,N'methylenebisacrylamide at a mass ratio of 17:1 to prepare a mixture, and then mix the mixture with water at a mass ratio of 18:85 Prepare the pre-preparation solution by mixing, add 0.5% by mass of dispersant, powdery 3Y-TZP with a purity greater than 99% and a particle size of less than 0.5 μm, and powdered Al with a purity of 99% and a particle size of 1 μm in the pre-preparation solution 2 o 3 Prepare a suspension with a pH value of 9.5 and a solid phase volume fraction greater than 50%. Put the suspension in a ball mill and pulverize it for 12 hours to obtain a water system ceramic slurry suspension with a viscosity of less than 300mPa.S. The mixture is placed in a water system ceramic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com