Automatic weighing and material supplementing device for tobacco flake finished products

An automatic weighing and feeding technology, which is applied in the fields of tobacco, tobacco preparation, and cigarette manufacturing, can solve the problems of increasing the packing and binding speed, shorten the packing time of tobacco leaves, reduce potential safety hazards, and improve the automation of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

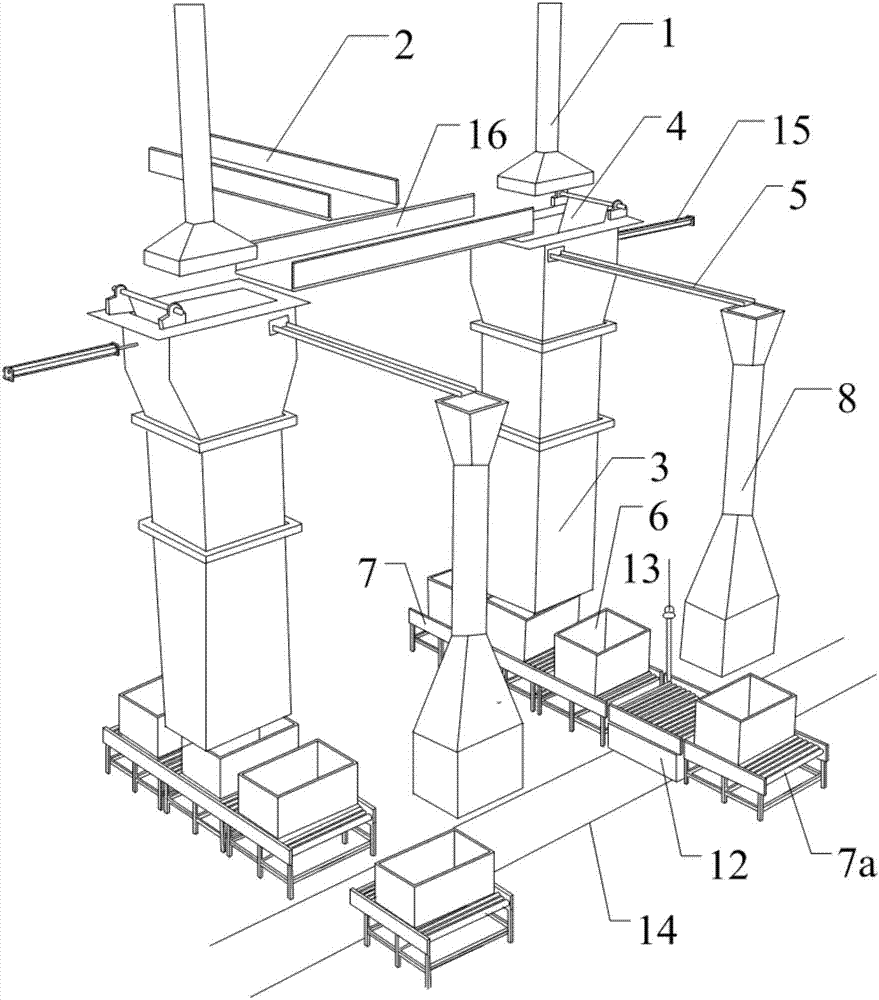

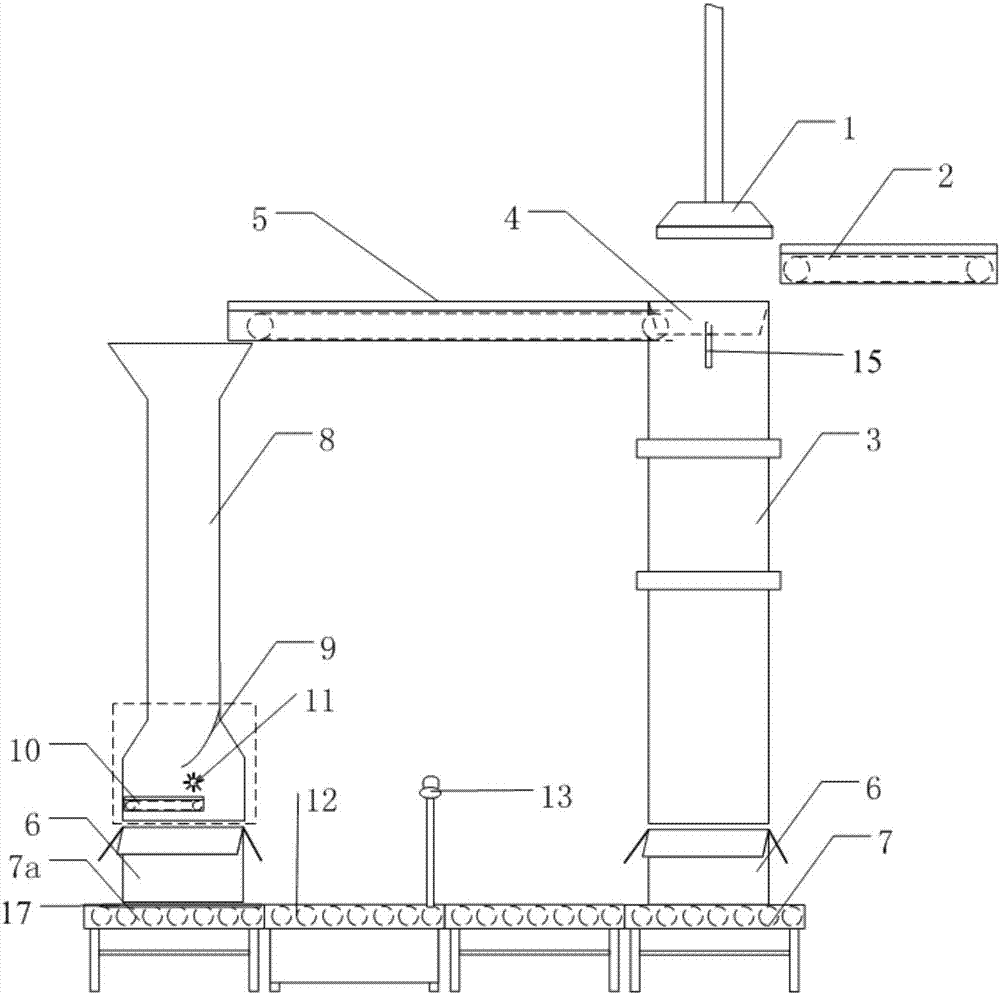

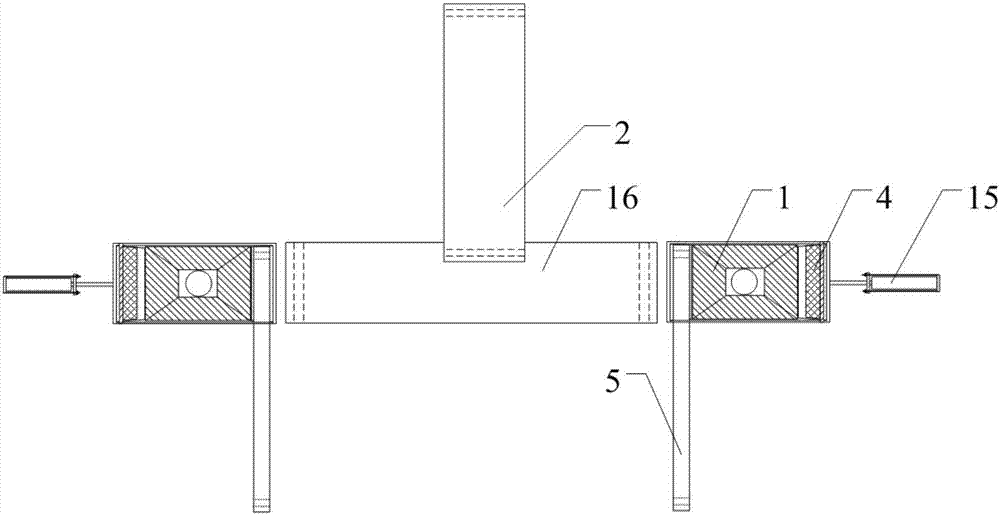

[0026] Such as Figure 1-Figure 4 As shown, the feeding device includes a conveyor belt 2, the discharge end of the conveyor belt 2 is equipped with a cross-feeding belt 16, and the vertical direction at the two ends of the cross-feeding belt 16 is respectively equipped with a pre-pressing pipeline 3, and the cross-feeding The material belt 16 is bidirectional feeding, and the motor can drive the conveyor belt 16 to rotate forward and reversely.

[0027] The side direction of each pre-pressing pipeline 3 is provided with replenishing bin 8, and the bottom of each pre-pressing pipeline 3 is provided with the first conveying roller 7, and the smoke box 6 that packs finished product is used is positioned on the first conveying roller 7, so The bottom of the replenishment bin 8 is provided with a second transport roller 7a, a track 14 is arranged between the first transport roller 7 and the second transport roller 7a, a transfer trolley 12 is arranged on the track 14, and the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com