Component clamping device

A clamping device and component clamping technology, applied in vices, manufacturing tools, etc., can solve the problems of reduced processing efficiency and long time, and achieve the effects of improving processing efficiency, low manufacturing cost, and preventing falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

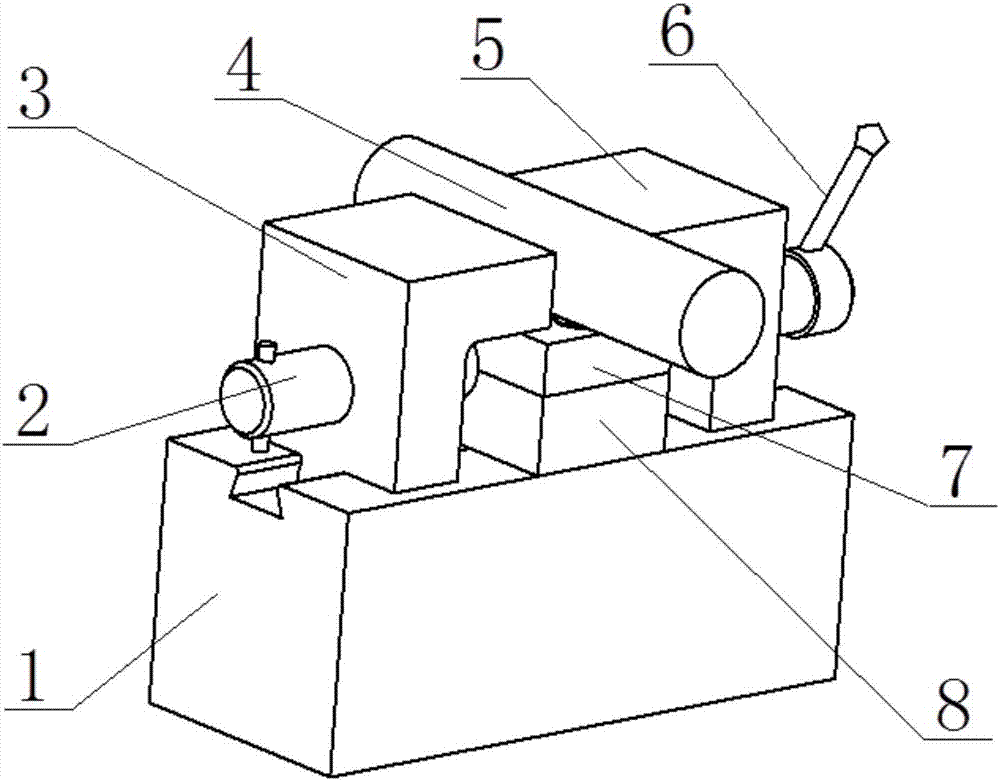

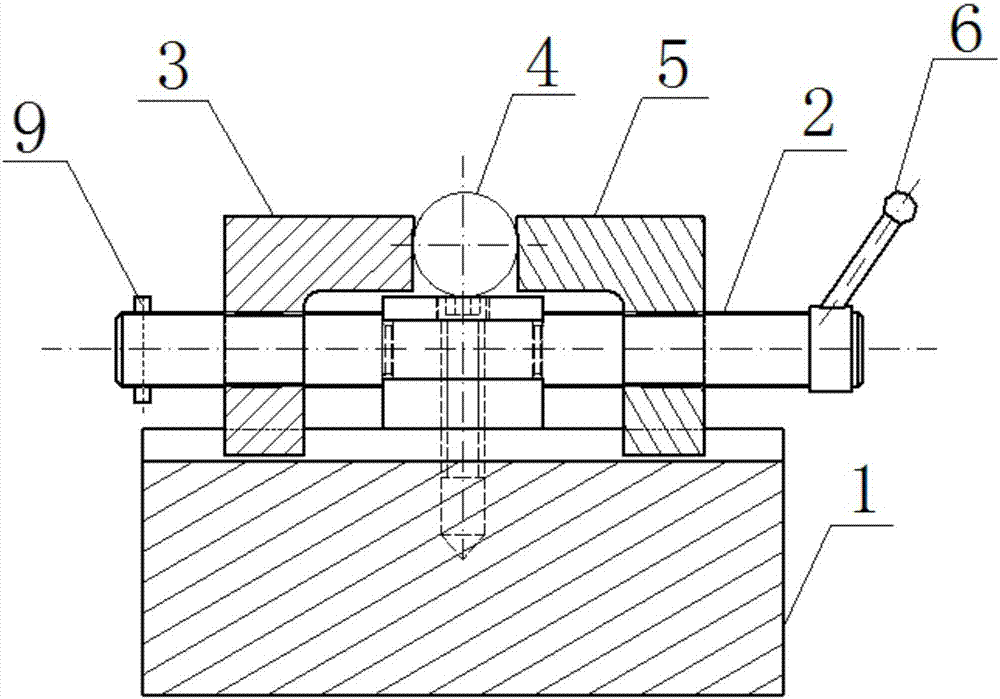

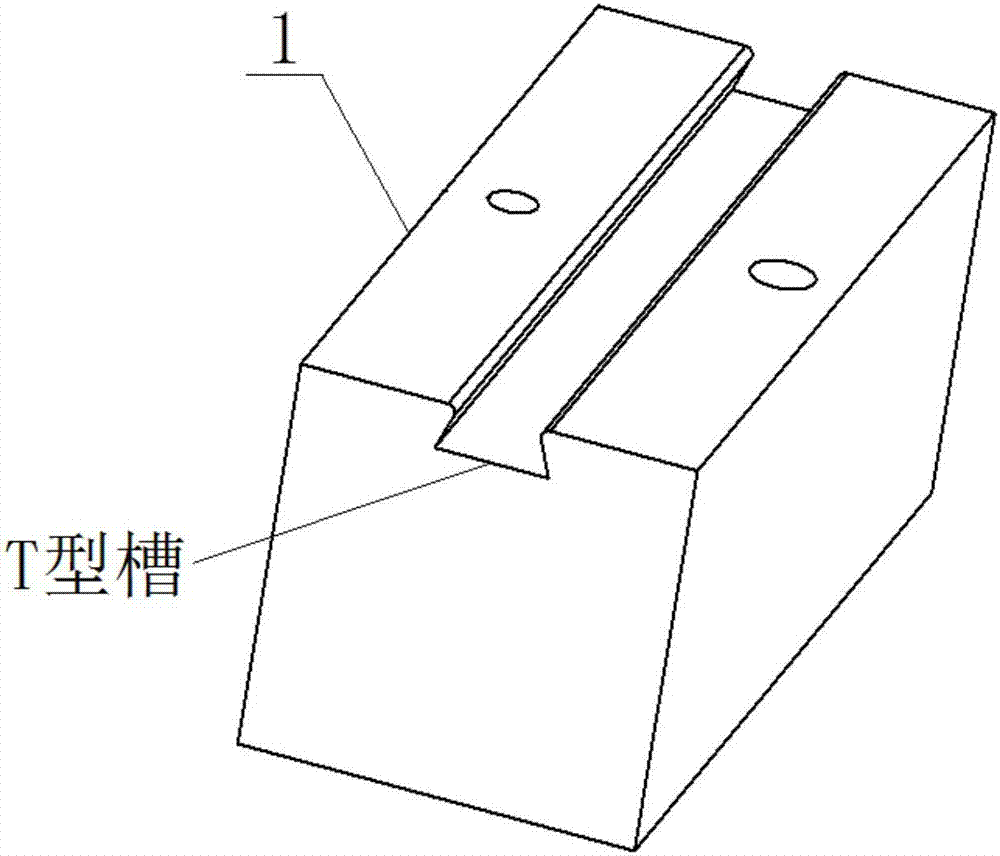

[0030] One of the embodiments of the mounting member clamping device is as follows: first place the lower clamp block 8 on the upper surface of the base 1, then place the middle part of the threaded rod 2 on the lower clamp block 8, and then place the upper clamp block 7 is placed on the lower clamp block 8. At this time, the threaded rod 2 is clamped between the upper clamp block 7 and the lower clamp block 8, and because the diameter of the middle part is smaller than that of the two ends, the diameter of the threaded rod 2 is limited. Move axially; then insert the left clamping block 3 and the right clamping block 5 into the two ends of the threaded rod 2 respectively, at this time the T-shaped grooves at the bottom of the left clamping block 3 and the right clamping block 5 all enter the base 1 In the T-shaped boss 10 in the middle; finally, the handle 6 and the pin 9 are installed on the two ends of the threaded rod 2 respectively.

[0031] When using the component clampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com