Multifunctional fodder vibration screening machine

A vibrating sieving machine, multi-functional technology, applied in the direction of feed, filter screen, solid separation, etc., can solve the problems of poor dust prevention effect, inconvenient transportation of feed, poor shock absorption effect, etc., to achieve convenient installation and good ventilation , the effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

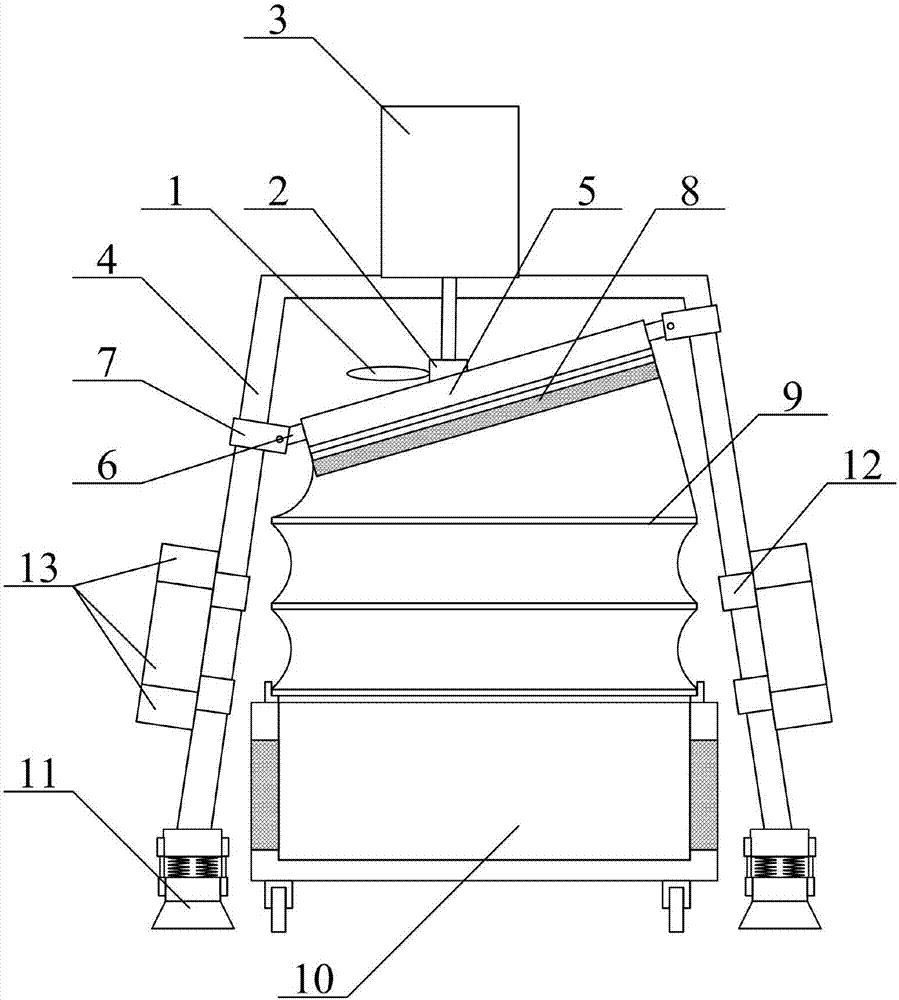

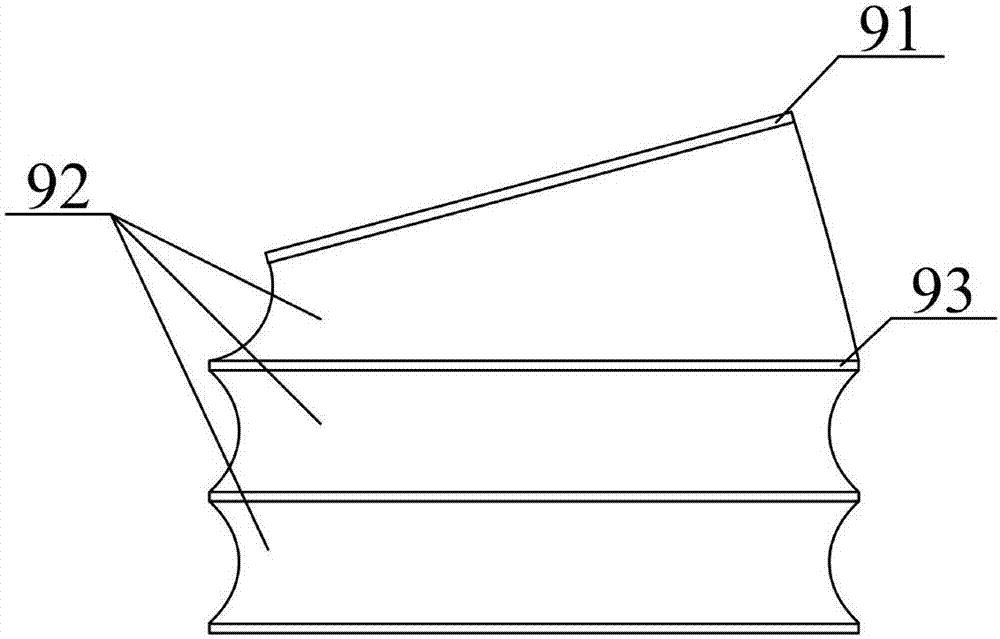

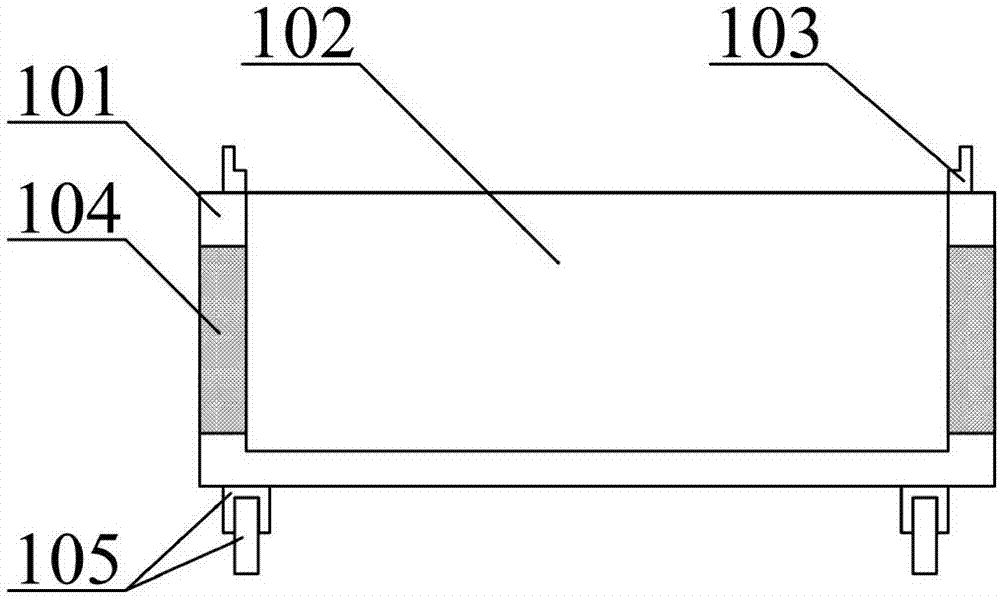

[0029] as attached figure 1 to attach Figure 4 shown

[0030] The present invention provides a multi-functional feed vibrating sieving machine, comprising a stirring paddle 1, a connecting block 2, a rotating motor 3, a bracket 4, a sieving box 5, a connecting rod 6, a hoop 7, a sieving net 8, and a dustproof Cover structure 9, feeding truck device 10, shock-absorbing base device 11, mounting block 12 and vibration motor 13, the stirring paddle 1 is respectively welded to the middle position of the left and right parts of the connecting block 2, and the connecting block 2 sets Connected to the output shaft of the rotating electrical machine 3, the rotating electrical machine 3 is bolted to the upper middle position of the support 4, and the connecting rod 6 is welded to the left and right parts of the screen box 5 respectively, and the connecting rod 6 The pins are respectively connected to the left and right parts of the hoop 7, the hoop 7 is clamped on the inner upper par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com