Suction disc adjusting device for paper and plastic packaging machine

A suction cup adjustment and packaging machine technology, applied in the direction of packaging, transportation and packaging, packaging/bundling items, etc., can solve the problems of difficult placement of operating tools, troublesome adjustment of suction nozzles, wear and tear of sequence guide rails, etc., to achieve simple structure and eliminate cylinders Easy to damage and the stroke is not in place, the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

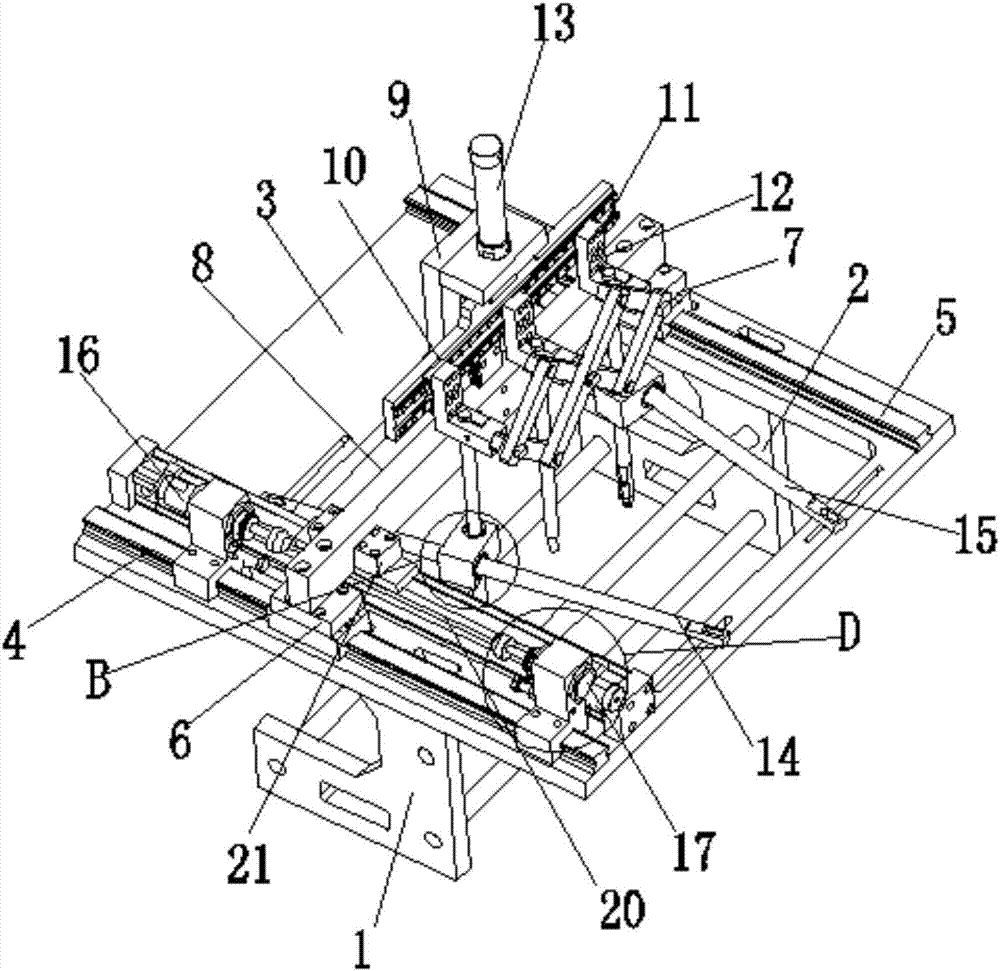

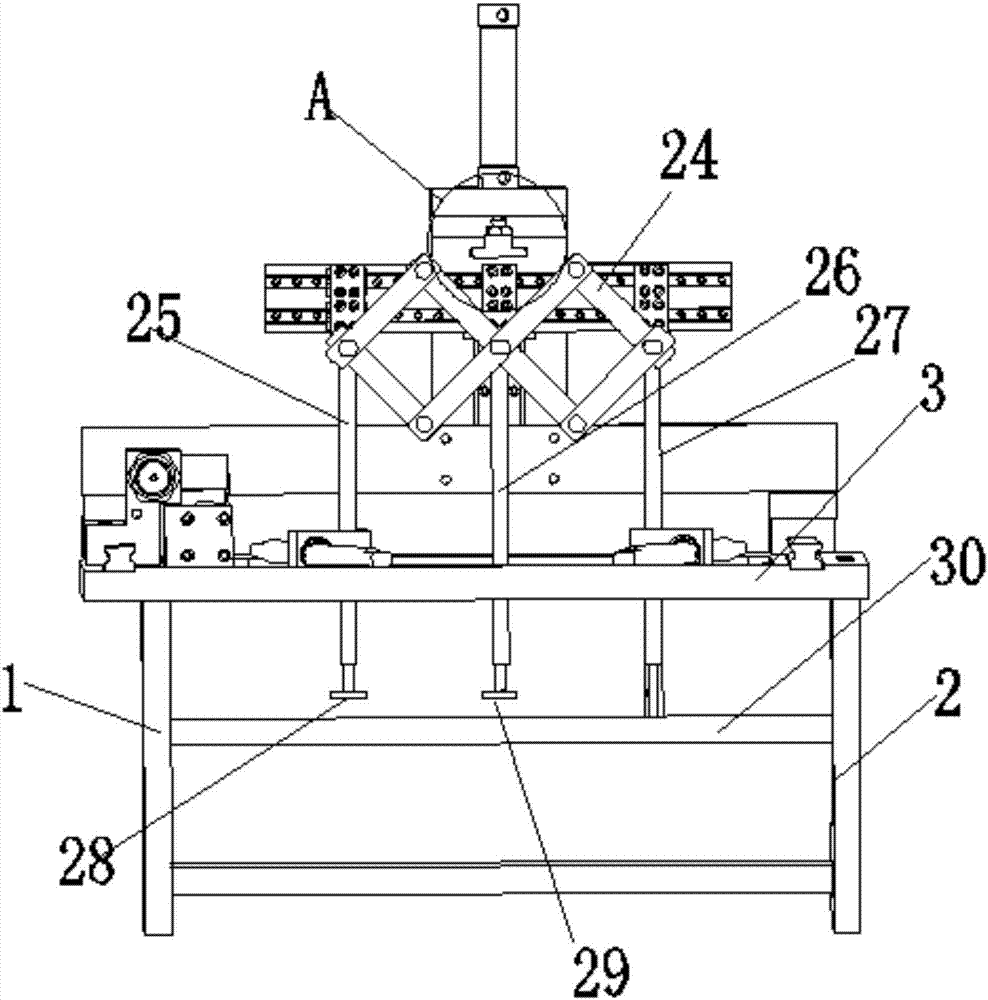

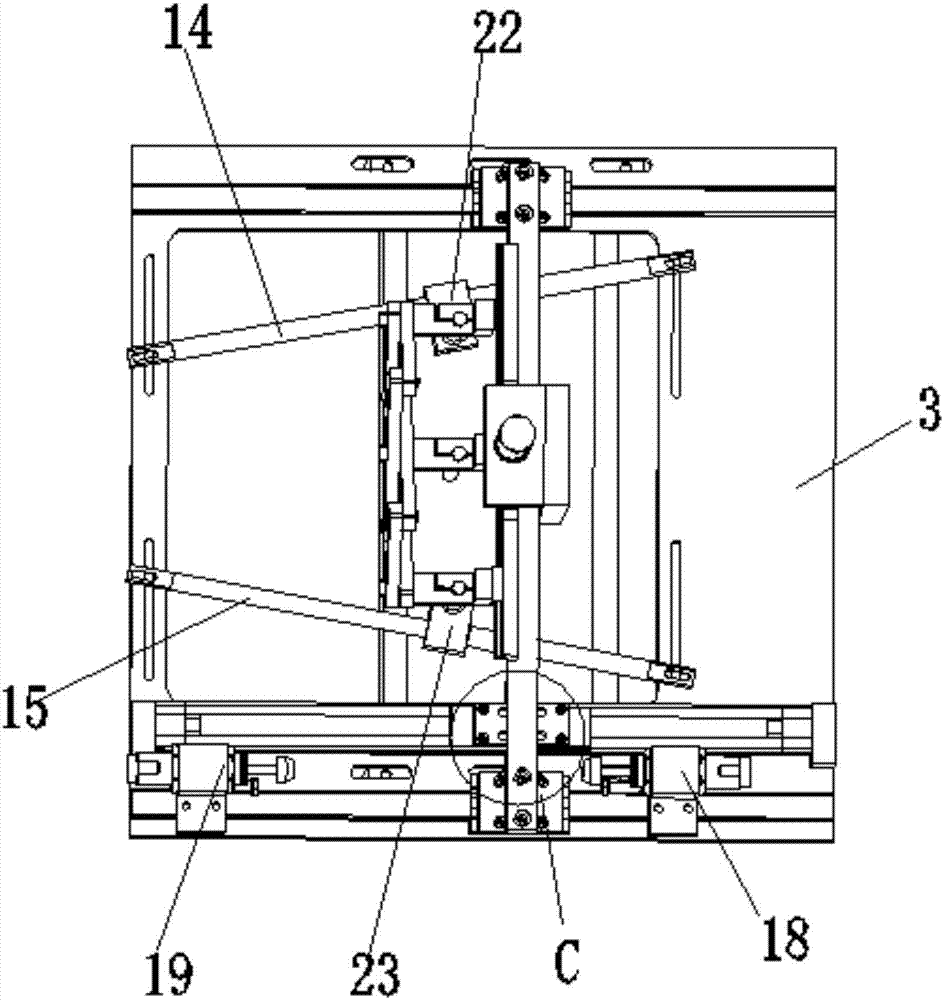

[0022] Such as figure 1 and combine Figure 2 to Figure 4 As shown, a suction cup adjustment device for a paper-plastic packaging machine includes a first support 1, a second support 2 and a frame 3, and the left and right ends of the frame 3 are erected on the first support 1 and the second support respectively. The upper end of the seat 2, the upper left and right sides of the frame 3 are respectively provided with a first slide rail 4 and a second slide rail 5, and several guide rods are passed between the first support 1 and the second support 2 30 connection, the upper part of the first slide rail 4 is set with the first connecting rod 6, the upper part of the second slide rail 5 is set with the second connecting rod 7, the first connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com