Test device and test method for simulating soil arching effect

A technology for simulating test and soil arching effect, applied in soil material testing, material inspection products, etc., can solve problems such as inability to study soil arching effect, failure to study pipe culvert or box culvert soil arching effect, lack of soil arching effect test equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

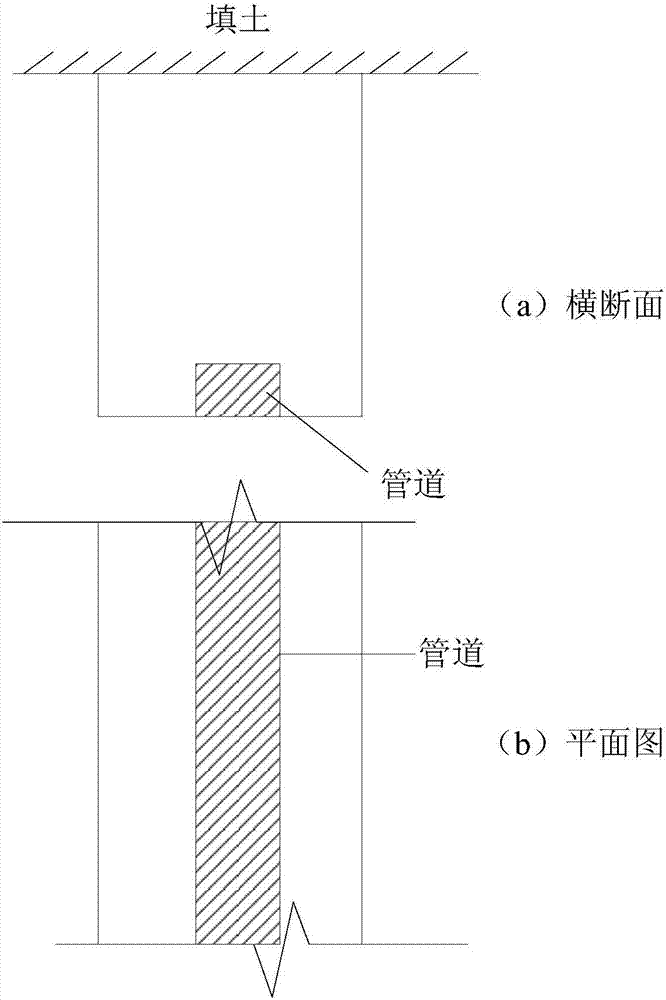

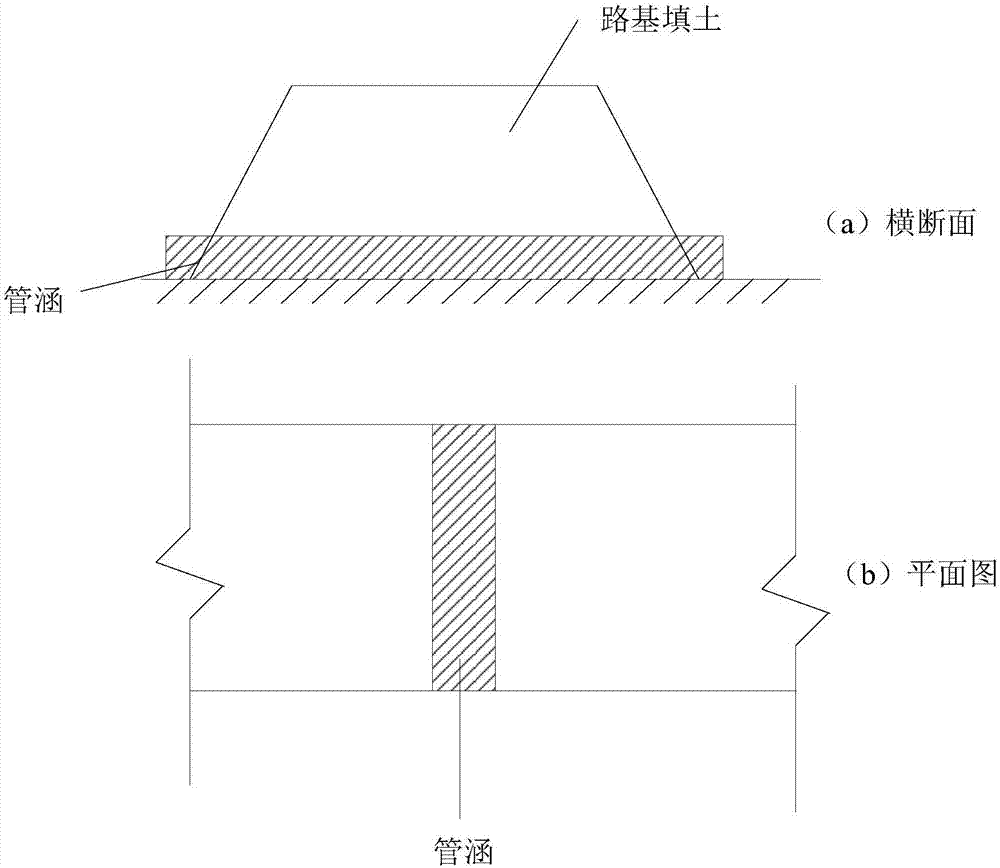

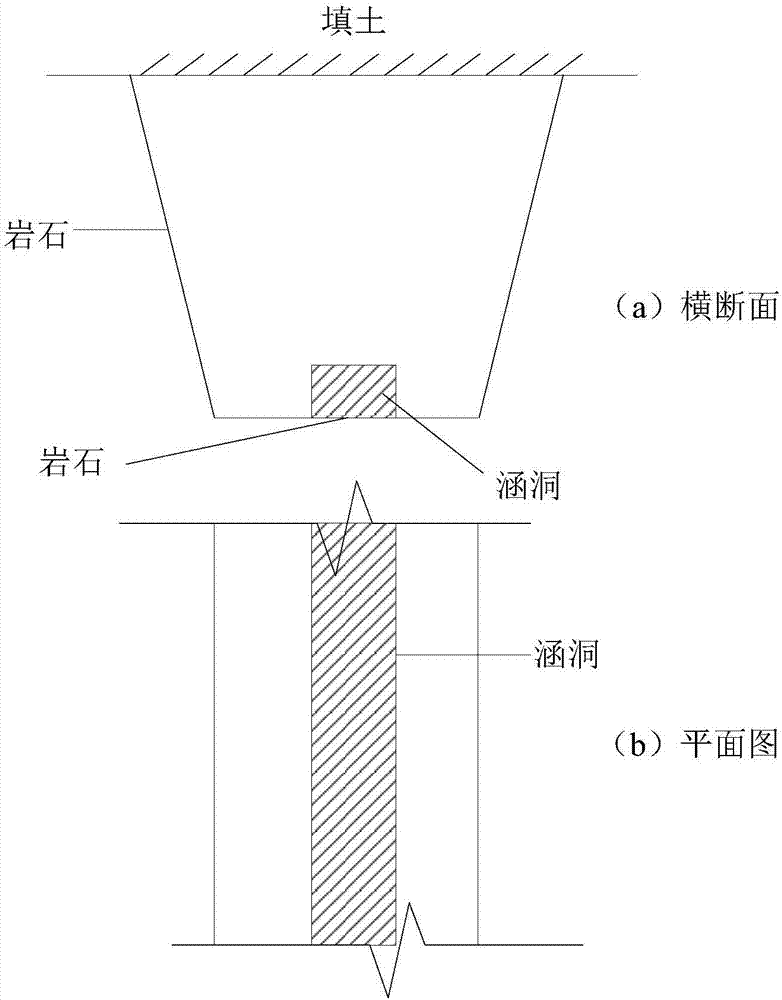

[0056] Example 1: Simulation of soil deformation of subgrade pipe culvert filling: pipe culvert / box culvert is perpendicular to the subgrade, and its foundation adopts cushion foundation;

[0057] As attached Figure 5-11 As shown, the soil arching effect simulation test device includes: a frame, a test box 4, and a lifting device 6;

[0058] Among them, the frame includes two upper beams 1-1, two lower beams 1-4, two platform beams 1-2, four columns 2, 6 longitudinal beams 1-3, platform beams 1-4 and longitudinal beam 1 -3 is provided with a load-bearing platform 3, and the test box 4 is fixed on the load-bearing platform 3; two longitudinal beams 1-3 are set at the positions of the upper beam 1-1 and the lower beam 1-4 to form a frame frame;

[0059] The test box 4 is composed of the main frame 4-1 of the box body and the surrounding plexiglass 4-2. The main frame 4-1 includes the upper beam, the lower beam and four columns. The lower beam and the four columns are provided with gla...

Embodiment 2

[0075] Embodiment two, combined with Figure 12-13 In the first embodiment, because there is a transverse keel below the settlement unit plate 5-4, the vertical displacement can only reach the height of the settlement unit plate higher than the non-settlement unit plate (equivalent to the height of the culvert higher than the original ground fill), Therefore, the first embodiment cannot simulate the situation where the culvert is located below the original ground height, which is equivalent to the situation where the surface of the settlement unit plate 5-4 is lower than the non-settlement unit plate 6-3.

[0076] Attached Picture 12 It can be seen that the settlement unit plate 5-4 is an integral plate. Compared with the original embodiment 1, the transverse keel under the settlement unit plate 5-4 is eliminated; this setting method can simulate the settlement of the settlement unit plate when it undergoes greater settlement deformation. Soil arching effect.

[0077] In order to ...

Embodiment 3

[0078] Embodiment 3: Combination Figure 14-16 Understand, single pipe culvert simulation under plane strain conditions: as attached Figure 14 As shown, the diameter of the pipe culvert is 1m, the total width of the backfilled soil is 2m, and the backfill height is 2m. According to the simulation of the ratio of 1:2, the settlement unit plate 5-4 is set in the middle with a width of 0.5m. Set a 0.25m non-settlement unit plate on each side, the length of the settlement unit plate and the non-settlement unit plate are both 2m and both are integral plates, and the non-settlement unit plate is directly fixed on the side wall of the box by screws or other methods;

[0079] By the attachment Figure 15-16 It can be seen that a row of jacking pipes 6-3 is uniformly distributed along the settling unit plate, the number of jacking pipes is 4, and the distance between the jacking pipes is 0.5m;

[0080] The cross-sectional graphics of the settlement unit plate 5-4 are: the upper semicircle a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com