Soil arching test box and method

A test box and soil arch technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of complex structure, inconvenient use, and many parts, and achieve simple operation, easy observation, The effect of simplifying the structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

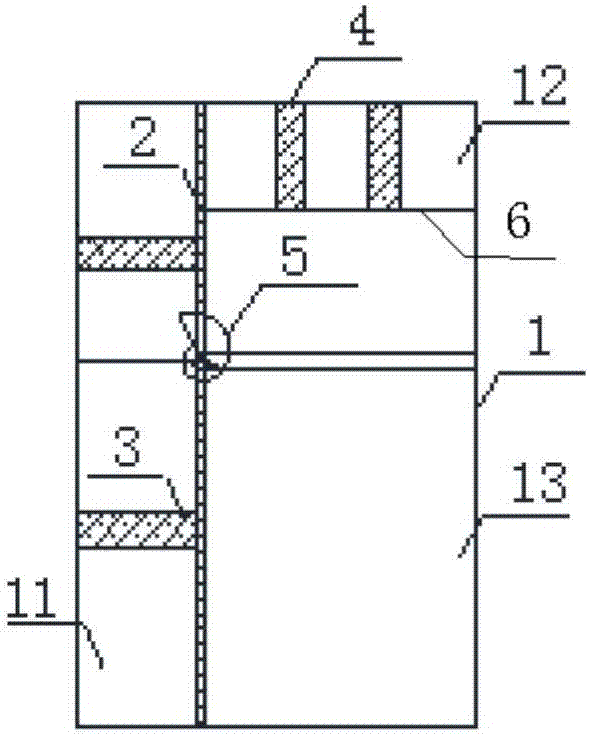

[0043] Such as figure 1 As shown, a soil arch test box includes a box body 1 , a soil arch test chamber 13 arranged in the box body 1 , a variable-diameter arch tool 5 , a horizontal pressurization system 3 and a vertical pressurization system 4 .

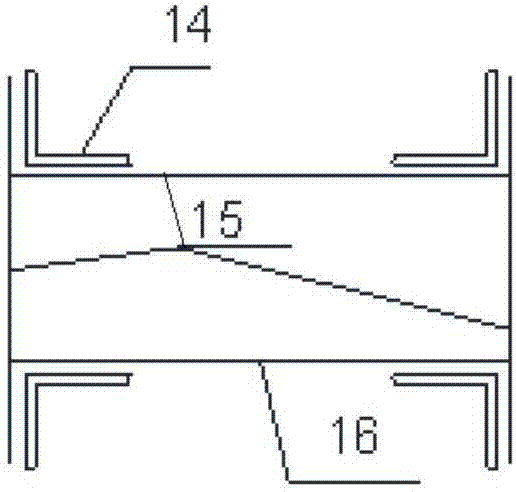

[0044] The box body 1 is a prism with an open lower end. In this embodiment, the box body 1 is a cuboid with a length of 1000 mm, a width of 300 mm and a height of 1500 mm. The side wall of the box body 1 adopts steel plates 15, and the two connected steel plates 15 are fixedly connected by equilateral angle steel 14 and bolts. The connection relationship between each steel plate 15 is as follows figure 2 As shown, the two sides of each equilateral angle steel 14 are respectively attached to two adjacent steel plates 15, and the bolts passing through the angle steel 14 and the steel plates 15 are fixedly connected, and the joints of the two steel plates 15 are sealed with engineering glue.

[0045] Each side wall of the box body...

Embodiment 2

[0067] A kind of test method that adopts the soil arch test box that embodiment 1 provides to measure soil arch effect, comprising:

[0068] Step 1, adjust the position of the horizontal movable plate 2 according to the pile spacing. That is, the horizontal movable plate 2 is pushed to a suitable position along the horizontal guide rail by the horizontal pressurization system 3 to obtain different pile spacings.

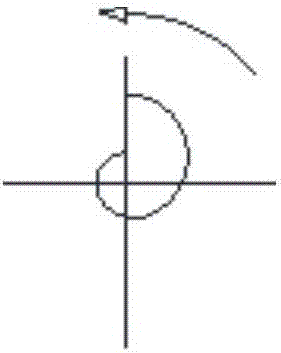

[0069] Step 2, setting the rotation angle of the variable-diameter arch 5 according to the size of the pile diameter. Through the different rotation angles of the variable-diameter arch 5, the side of the deformed arch facing the soil sample has different pile diameters.

[0070] In step 3, soil samples are filled into the soil arch test chamber 13 in layers from top to bottom, and the soil samples of each layer are separated by thin layers of heterogeneous soil samples. The shape of the soil arch structure is reflected by the texture of the heterogeneous soil samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com