Prefabricated mushroom-shaped pile cap for pile-supported reinforced embankment

A reinforced embankment and mushroom-shaped technology, which is applied in the field of geotechnical engineering foundation treatment, can solve the problems of poor quality controllability, easy damage, and long maintenance time, so as to improve the pile-soil load ratio and increase the pile-soil settlement difference , Improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments.

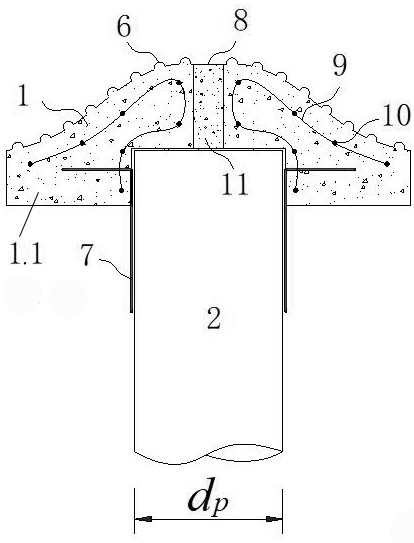

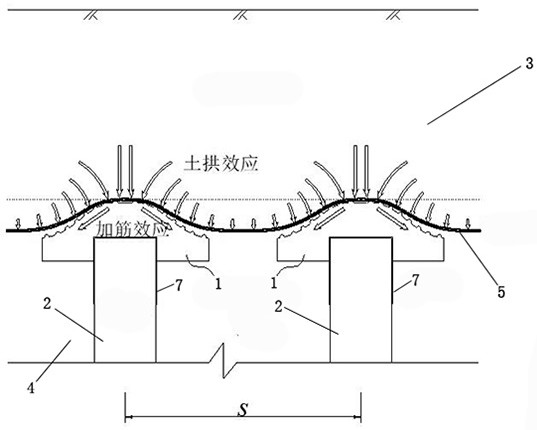

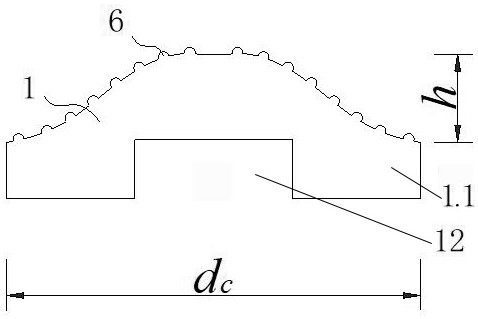

[0030] Such as figure 1 As shown, an assembled mushroom-shaped pile cap of a pile-supported reinforced embankment is characterized in that: the prefabricated pile cap 1 includes an abutment 1.1, and the upper surface of the abutment 1.1 protrudes upwards to form an arc surface, and the described The curved surface evenly extends from the top of the upper surface of the abutment 1.1 to the edge of the upper surface of the abutment 1.1;

[0031] The lower surface of the abutment 1.1 is provided with a reserved pile hole 12, and the top of the rigid pile 2 is embedded in the reserved pile hole 12 to be detachably connected with the prefabricated pile cap 1;

[0032] The upper surface of the abutment 1.1 is in close contact with the geotechnical reinforcement 5 .

[0033] After the upper surface of the prefabricated pile cap 1 protrudes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com