Tie-rod structure and construction method of tunnel cover excavation method of soil arch tire formwork in mountainous area

A technology for road tunnels and tie-rod structures, which can be used in infrastructure engineering, underwater structures, artificial islands, etc., and can solve problems such as potential safety hazards, high costs, and difficult control of slope soil deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0111] The embodiments of the present invention will be described in detail below according to the above-mentioned drawings.

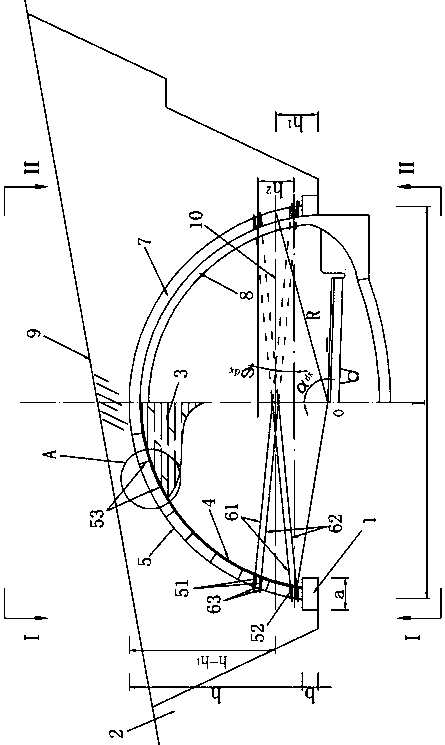

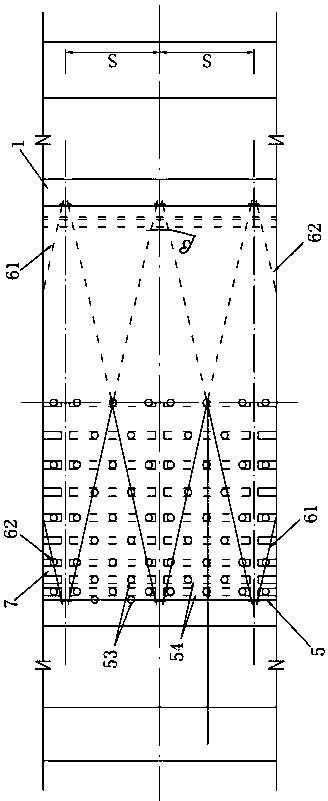

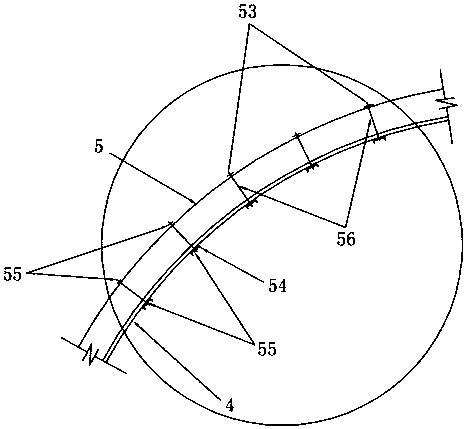

[0112] Such as Figure 1~Figure 5 As shown, 1. Arch foundation, 2. Slope, 3. Soil arch tire, 4. Wood formwork, 5. Steel formwork, 51. Two rows of reserved holes, 52. Tie rod casing, 53. Steel formwork tie rod , 54. Channel steel backing plate, 55. Tie rod bolt, 56. Tie rod sleeve, 61. Upper tie rod, 62. Lower rod, 63. Wedge-shaped backing plate, 64. Tie rod bolt, 7. Arch concrete, 8 .Secondary lining concrete, 9. Ground, 10. Equivalent tie rod axis, 11. Expansion settlement joint, 12. Settlement amount.

[0113] The earth arch tire formwork tie rod structure and its construction method of mountain road tunnel cover excavation method belong to the construction field of mountain road tunnel cover excavation method, and are mainly composed of foundation, side slope 2, soil arch tire 3, cover arch foundation 1, and cover arch concrete 7 and secondary lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com