Automatic punching device of cup body of temperature limiter

A technology of stamping equipment and temperature limiter, which is applied in the field of automatic stamping equipment for temperature limiter cups, can solve the problems of high cost, potential safety hazards, low work efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

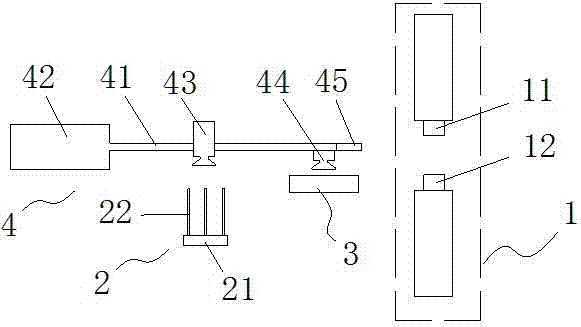

[0016] As shown in the figure, the automatic punching equipment for the temperature limiter cup body of this embodiment includes a punching table 1 provided with a punch 11 and a mold 12, and a feeding mechanism 4 for sending the raw material plate to the punching table 1, and the punching table 1 is provided with a raw material storage rack 2 on the side, and a flat raw material buffer table 3 is provided between the raw material storage rack 2 and the punch table 1, and the top surface of the raw material buffer table 3 is at the same level as the top surface of the mold 12 Above; the raw material plate storage rack 2 is composed of a base 21 and a plurality of magnetic rods 22 vertically arranged on the base 21, and the area between the magnetic rods 22 is the area for placing the raw material plate.

[0017] The feeding mechanism 4 includes a horizontal rod 41 and a horizontal reciprocating drive mechanism 42 connected to the horizontal rod 41 (a cylinder placed horizontall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com