Automatic packaging method and device for standard bricks

A standard and automatic technology, applied in the direction of packaging and binding machinery parts, etc., can solve the problems of large manpower consumption, low degree of automation, labor intensity, and difficulty in improving the economic benefits of enterprises.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

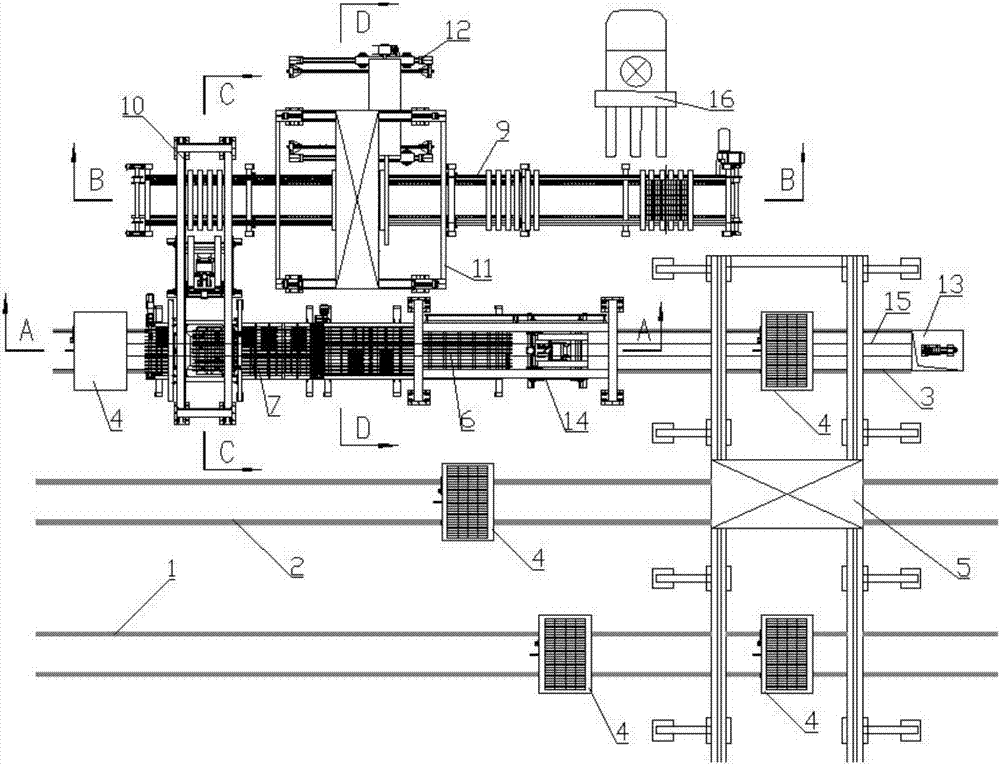

[0031] The preferred embodiments of the present invention are described in further detail below, so that those skilled in the art can understand more clearly. As the method of the present invention, the standard bricks produced are automatically packaged through the cooperation of a series of devices, so that To achieve the purpose of saving human resources and automating the packaging process, the method includes the following steps:

[0032] The clamping machine picks up the steam curing car with brick stacks on the track behind the kettle and transfers it to the return track;

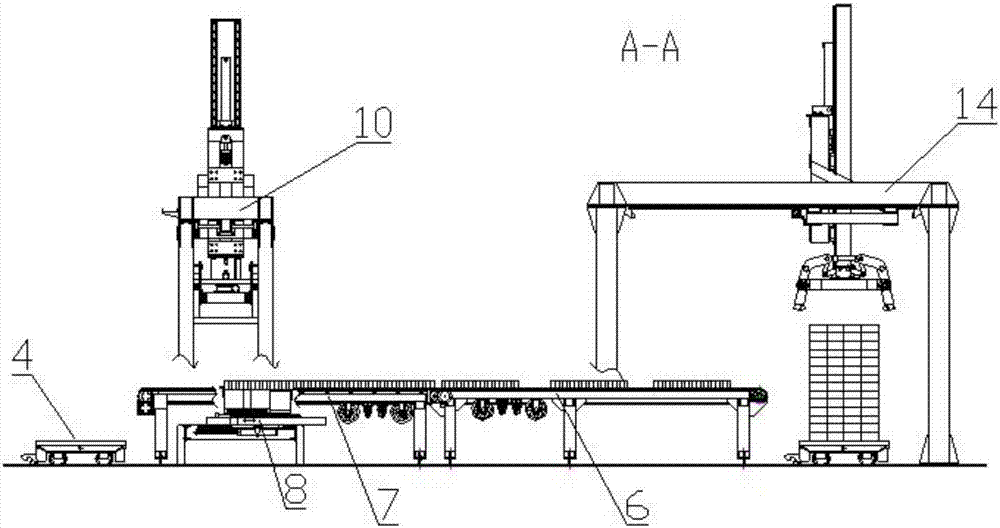

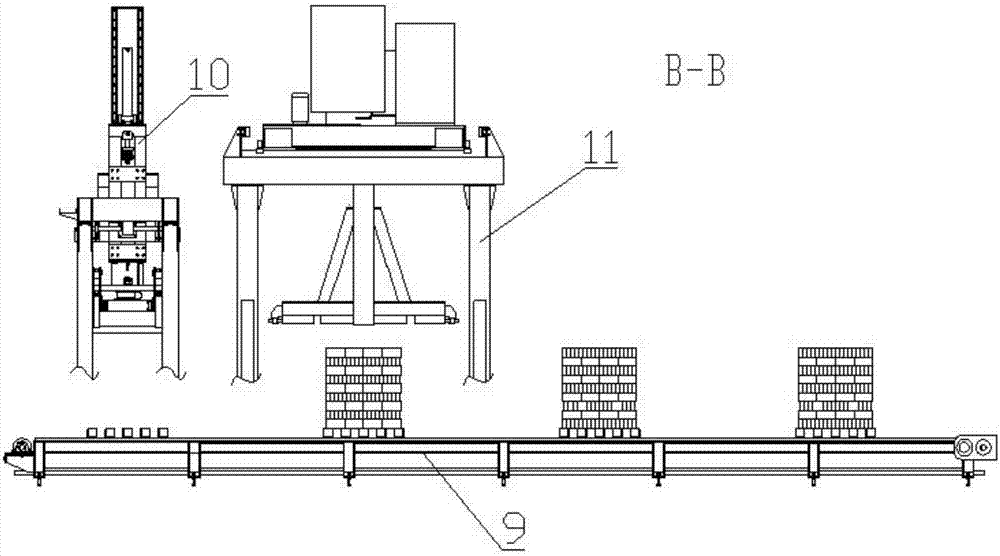

[0033] The push cart pushes the top of the steam curing cart loaded with brick stacks to the bottom of the depalletizer;

[0034] The depalletizer clamps the stacks of bricks on the steam curing car layer by layer and rotates them 90 degrees, and then places them in a single layer on the running first chain conveyor, so that the large surface of each standard brick is perpendicular to the first chain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com