Cylindrical work piece end surface hopping detection device

A columnar workpiece, end face runout technology, applied in measuring devices, mechanical measuring devices, mechanical devices, etc., can solve problems such as difficulty in adapting to mass production and rapid inspection, no cost and low end face inspection device, and expensive equipment, etc. Achieve fast positioning and flexible rotation, improve applicability and flexibility, and save detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below, the present invention will be described in detail with reference to the accompanying drawings and embodiments:

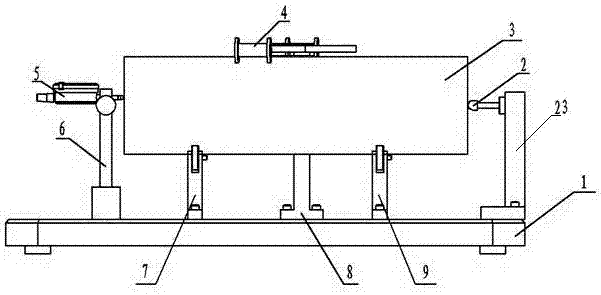

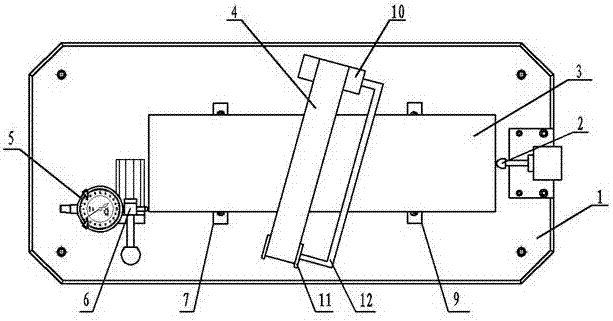

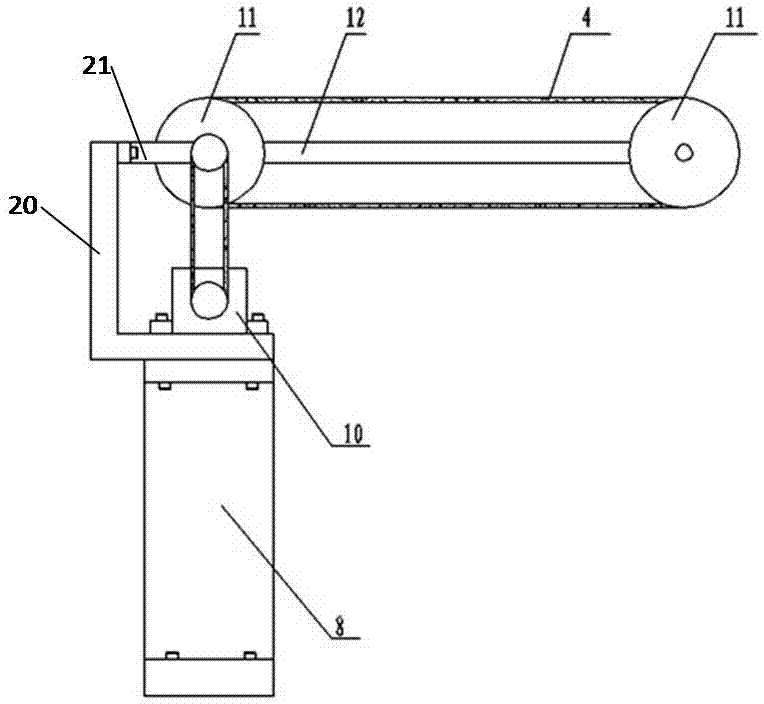

[0037] like Figures 1~7 As shown in the figure, a detection device for the end face jump of a columnar workpiece includes a bottom plate 1 placed on a horizontal plane. The bottom plate 1 is provided with a left support plate 7 and a right support plate 9 that support the rotation of the cylindrical workpiece 3. A support rod 23 is provided, the upper end of the support rod 23 is provided with a positioning head 2 for pressing the positioning end of the cylindrical workpiece 3, the upper end of the cylindrical workpiece 3 is provided with a transmission belt 4 that drives its rotation, and the bottom plate 1 is also provided with a measuring The indicator table 5 on the measuring end of the cylindrical workpiece 3, the axial included angle between the transmission belt 4 and the cylindrical workpiece 3 is an acute angle.

[0038] In the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com